Forward and reverse walking multi-legged platform

A platform and walking part technology, applied in the field of forward and reverse walking multi-legged transport platforms, can solve the problems of easy overturning of the walking transport platform and the inability of the transport platform to work, and achieves optimized foot end trajectory, outstanding load performance, and improved adaptability and reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

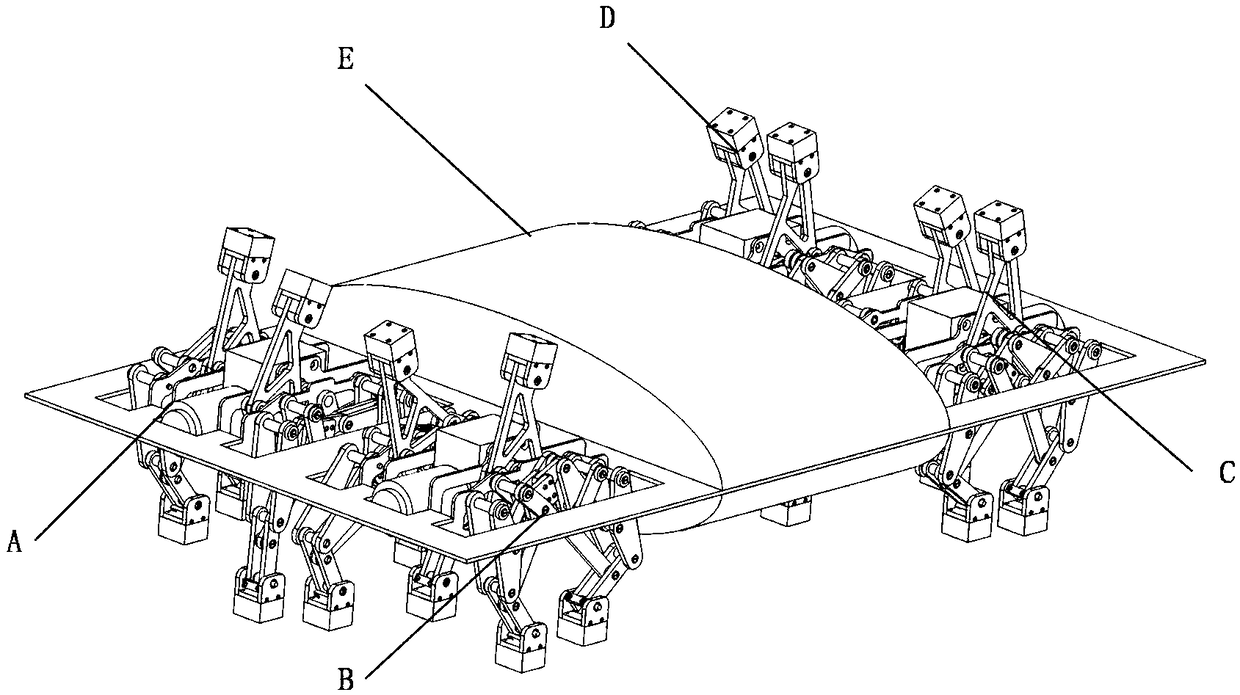

[0025] Such as figure 1 As shown, a forward and reverse walking multi-leg carrier platform is composed of first to fourth leg groups (A, B, C, D) and vehicle frame (E); the first to fourth leg groups (A, B, C, D) and the vehicle frame (E) are fixedly connected to realize the assembly of the whole machine; the first to fourth leg groups (A, B, C, D) are all driven by a single motor to walk; the second to the fourth leg groups The mechanical structure of the four-leg group (B, C, D) and the first leg group (A), the shape and size of the parts and the assembly method are completely consistent.

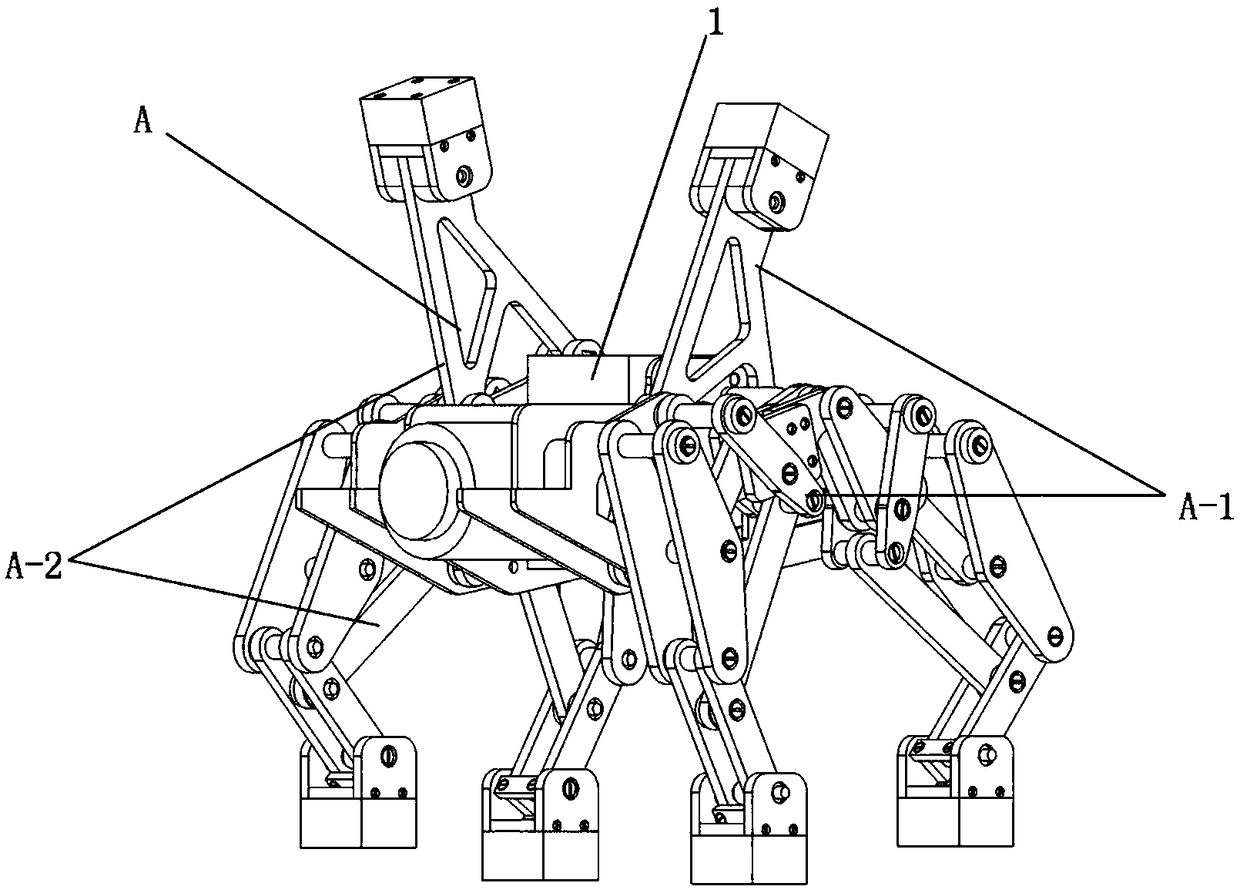

[0026] Such as figure 2 The first leg group (A) shown is composed of a left walking part (A-1), a right walking part (A-2) and a double output shaft motor (1); the left walking part (A-1 ), the right walking part (A-2) is respectively connected to the two ends of the double output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com