Spacecraft sinusoidal vibration test recessing condition formulation method

A sinusoidal vibration and spacecraft technology, applied in the field of spacecraft, can solve the problems of inability to do full-frequency comparison, heavy manual workload, hidden risks, etc., to avoid selective omissions, save waiting time, and optimize the test workflow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

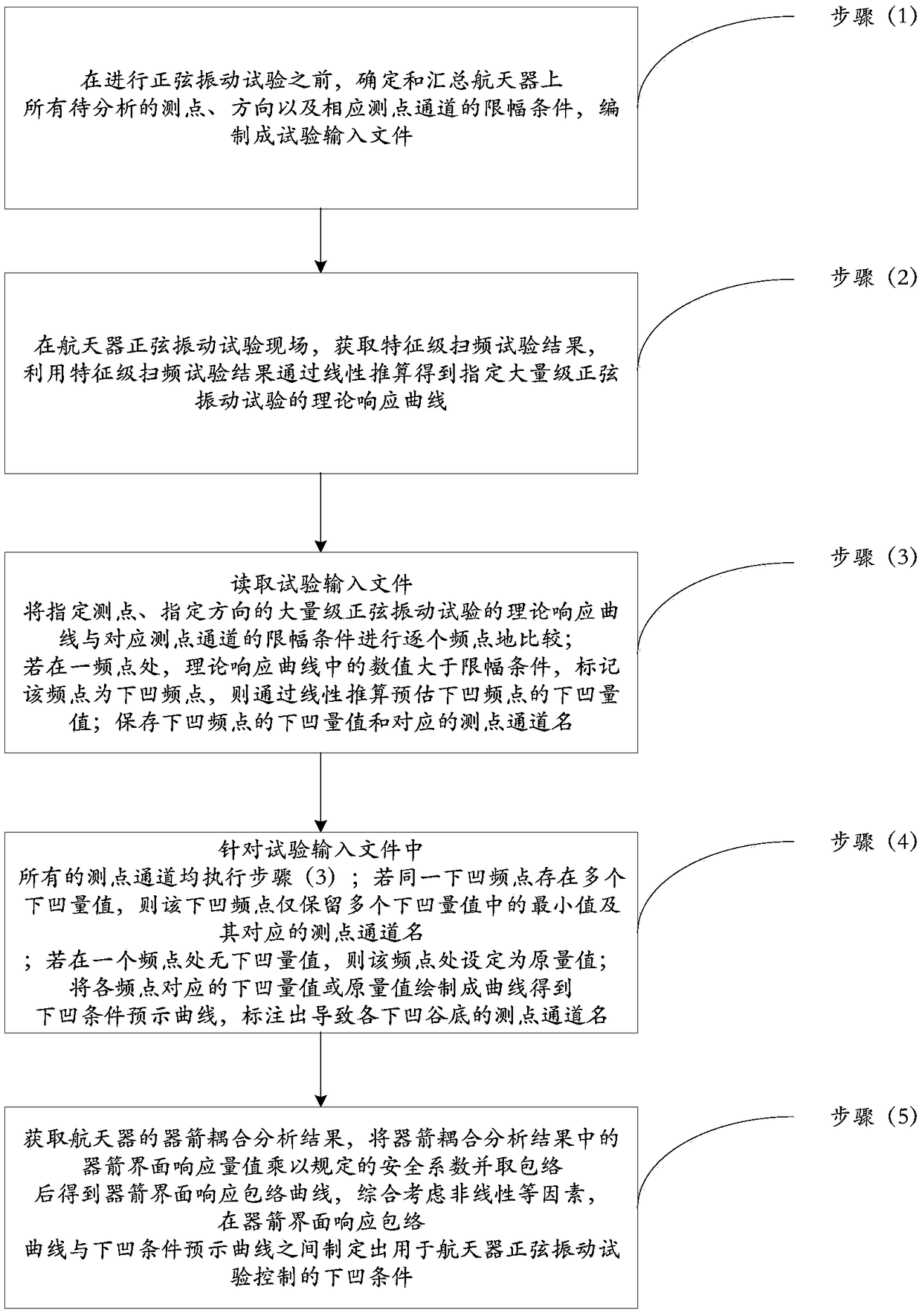

[0034] The present invention will be described in detail below with reference to the drawings and embodiments.

[0035] The invention provides a method for formulating the concave conditions of a spacecraft sinusoidal vibration test, which is strictly based on the concave control criterion of the spacecraft sinusoidal vibration test.

[0036] The sunken control criteria for spacecraft sine vibration test include:

[0037] Criterion 1: In the spacecraft sine vibration test, the maximum strain response of the main structure of the spacecraft shall not be greater than the maximum strain value of the main structure of the spacecraft in the static test.

[0038] Criterion 2: The acceleration response at the critical stand-alone equipment installation position on the spacecraft does not exceed the component-level sinusoidal vibration test conditions specified in the environmental test specification.

[0039] Criterion 3: The input vibration value of the entire spacecraft after the dent is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com