An apparatus and method for quickly regulating temperature and humidity of pipeline gas

A technology to adjust the temperature of pipelines and gases, applied in electrical components, fuel cell heat exchange, fuel cell additives, etc., can solve the problems of poor control accuracy, slow response to temperature and humidity changes, etc., and achieve small heat load and fast wall temperature change , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

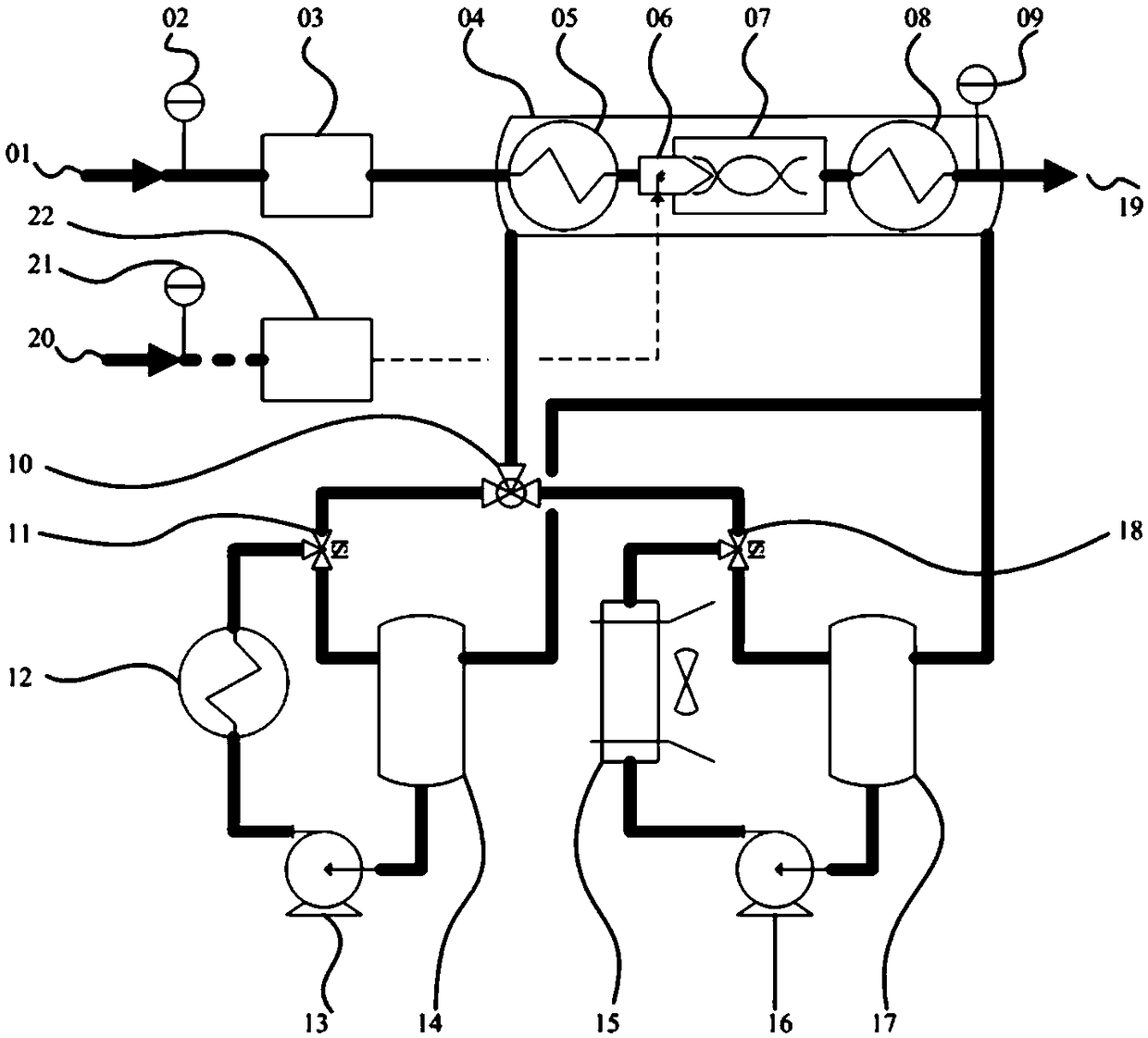

[0022] The gas and steam mixing system is sequentially connected by the gas source port 1, the temperature and humidity pressure detector A2, the gas flow controller 3, the preheater 5 and the nozzle 6, and the nozzle 6 is in contact with the mixer 7 and partially extends into the mixer 7 One end, the other end of the mixer 7 are sequentially connected with the thermostat 8, the temperature and humidity pressure detector B9 and the output port 19, and another branch is provided, the steam inlet 20, the steam temperature and pressure detector 21, the steam flow controller 22 and the nozzle 6 connected in sequence, the preheater 5, the nozzle 6, the mixer 7 and the thermostat 8 are covered with the same jacket 4, the inlet of the jacket 4 is connected with one end of the mixing valve 10, and the other two ends of the mixing valve 10 are respectively connected with One end of the thermal agent three-way valve 11 is connected with one end of the refrigerant three-way valve 18, and ...

Embodiment 2

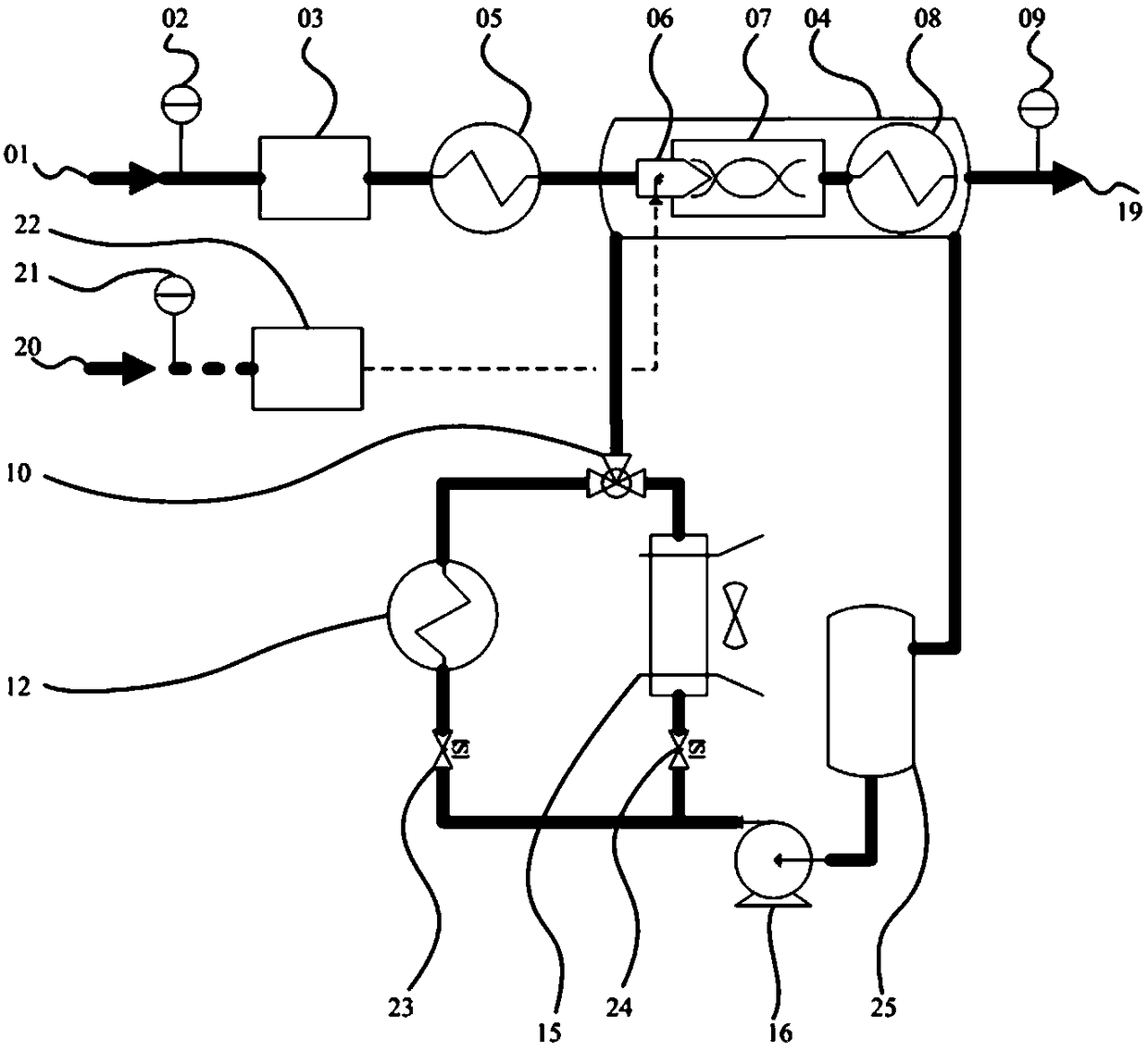

[0025] The gas and steam mixing system is connected in sequence by gas source port 1, temperature and humidity pressure detector A2, gas flow controller 3, preheater 5 and nozzle 6, nozzle 6, mixer 7, thermostat 8, temperature and humidity pressure detection The device B9 is connected to the output port 19 in sequence, and another branch is provided. The steam inlet 20, the steam temperature and pressure detector 21, and the steam flow controller 22 are connected to the nozzle 6 in sequence. The nozzle 6, the mixer 7 and the thermostat 8 are connected outside Covered with the same jacket 4, the inlet of the jacket 4 is connected to one end of the mixing valve 10 through a pipeline, and the other two ends of the mixing valve 10 are respectively connected to the thermal agent heater 12 and the chiller 15, and the thermal agent heater 12, the heater front Proportional regulating valve 23, refrigerant pump 16 are connected to circulating liquid storage pump 25, circulating liquid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com