Multi-material material discharging device for food 3D printer

A 3D printer and discharging device technology, applied in the field of food printers, can solve the problems of inconvenient nutrient ratio, color, taste and taste adjustment, less variety, etc., and achieve the effect of good fusion effect, taste adjustment, and taste adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

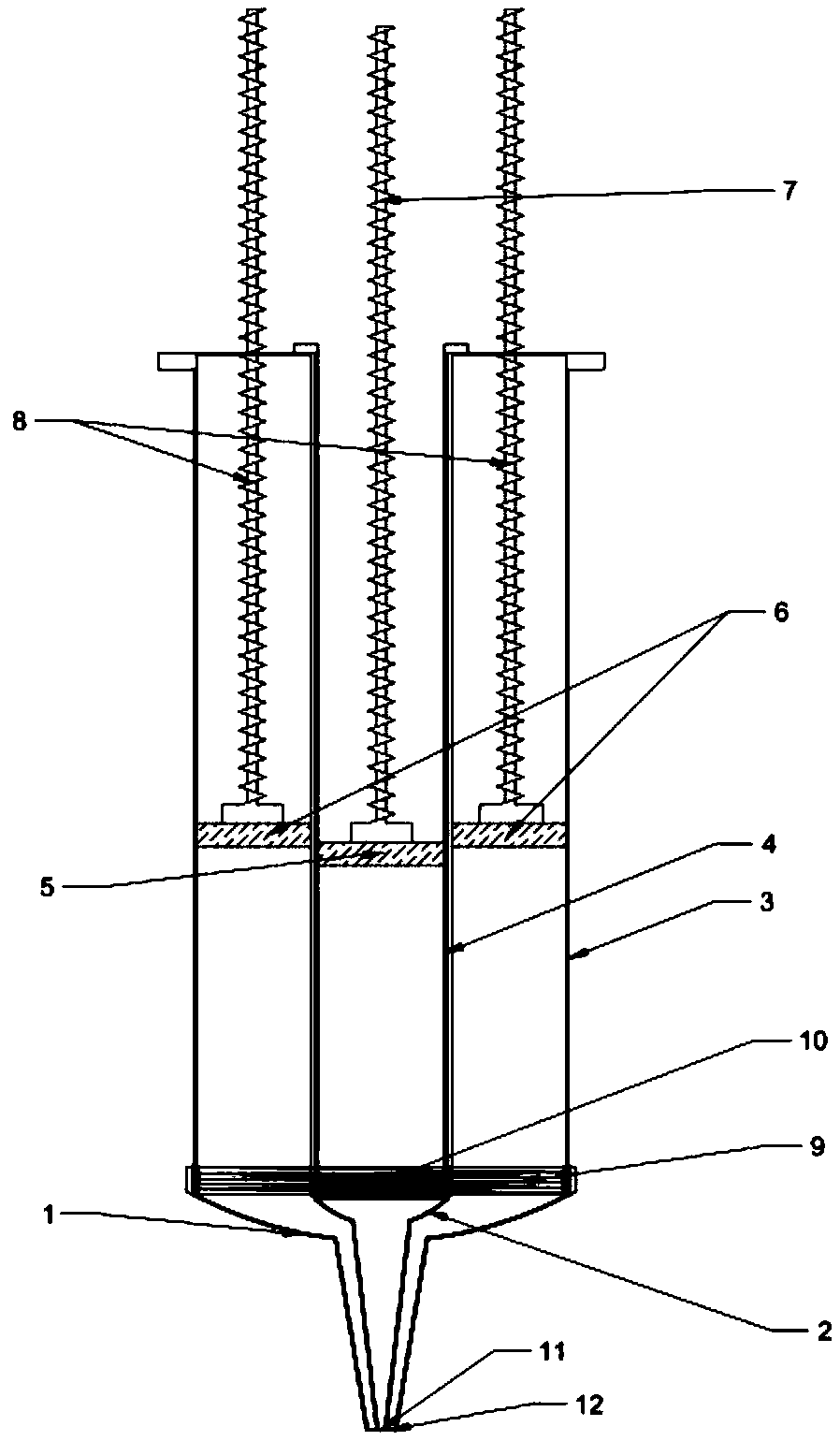

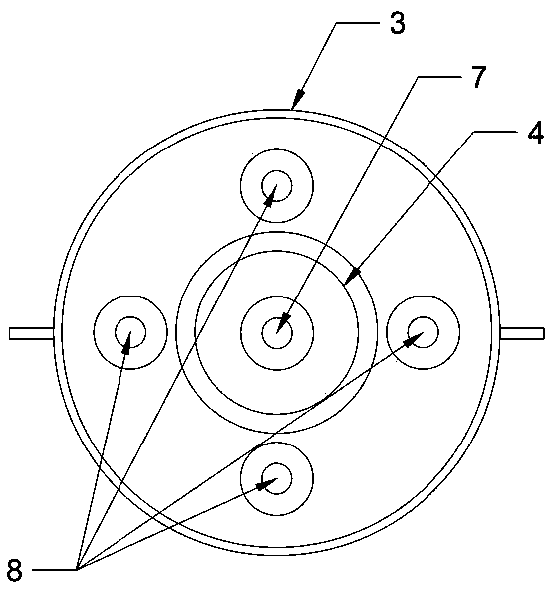

[0041] Such as figure 1 As shown, the multi-material discharge device of the food 3D printer provided by the embodiment of the present invention includes an outer cylinder 3 and an inner cylinder 4 that are sleeved. The outer cylinder 3 and the inner cylinder 4 have independent material accommodation spaces. The outer cylinder 3 The lower end is threadedly connected with the printing outer head 1, and the lower end of the inner cylinder 4 is connected with the printing inner head 2, wherein the printing inner head 2 is set inside the printing outer head 1, and the printing outer head 1 and the outer cylinder 3, and the printing inner head 2 and the inner cylinder 4 are independently connected, and the printing inner head 2 forms an independent printing inner extrusion hole 11, and the printing outer head 1 forms an independent printing outer extrusion hole 12. In order to facilitate independent discharge, such as figure 1 As shown, the outer cylinder 3 and the inner cylinder ...

Embodiment 2

[0054] The difference between the multi-material discharge device of the food 3D printer in this embodiment and the first embodiment is that the outer cylinder can be divided into a plurality of mutually independent material chambers along its circumference; and / or the inner cylinder can be separated along its circumference. Circumferentially divided into multiple chambers independent of each other.

[0055] That is to say, several partitions can be arranged at intervals in the circumferential direction of the outer cylinder, and the length extension direction of each partition is consistent with the axial direction of the outer cylinder, thereby dividing the outer cylinder into a plurality of independent material chambers connected up and down. And / or a plurality of baffles may be arranged in the inner cylinder, and the length extension direction of the baffles is consistent with the axial direction of the inner cylinder, so as to divide the inner cylinder into a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com