A feed crushing and mixing device

A technology for mixing device and feed, which is applied to mixer accessories, transportation and packaging, mixers, etc., can solve problems such as waste, and achieve the effects of improving utilization rate, improving crushing efficiency, and novel and practical overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

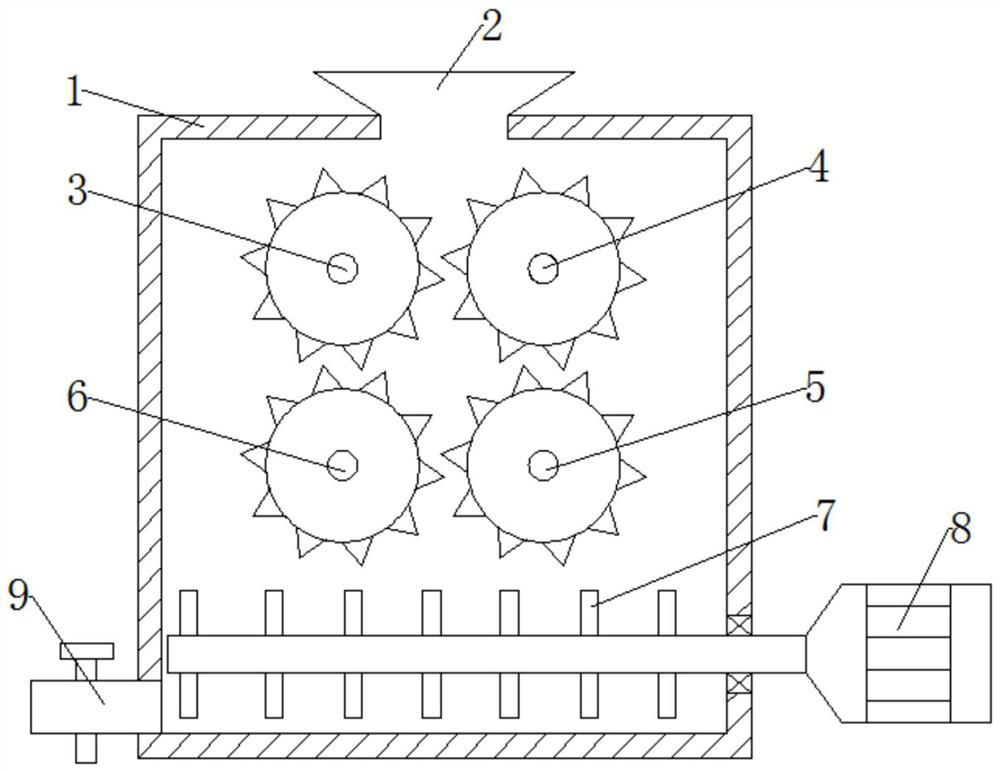

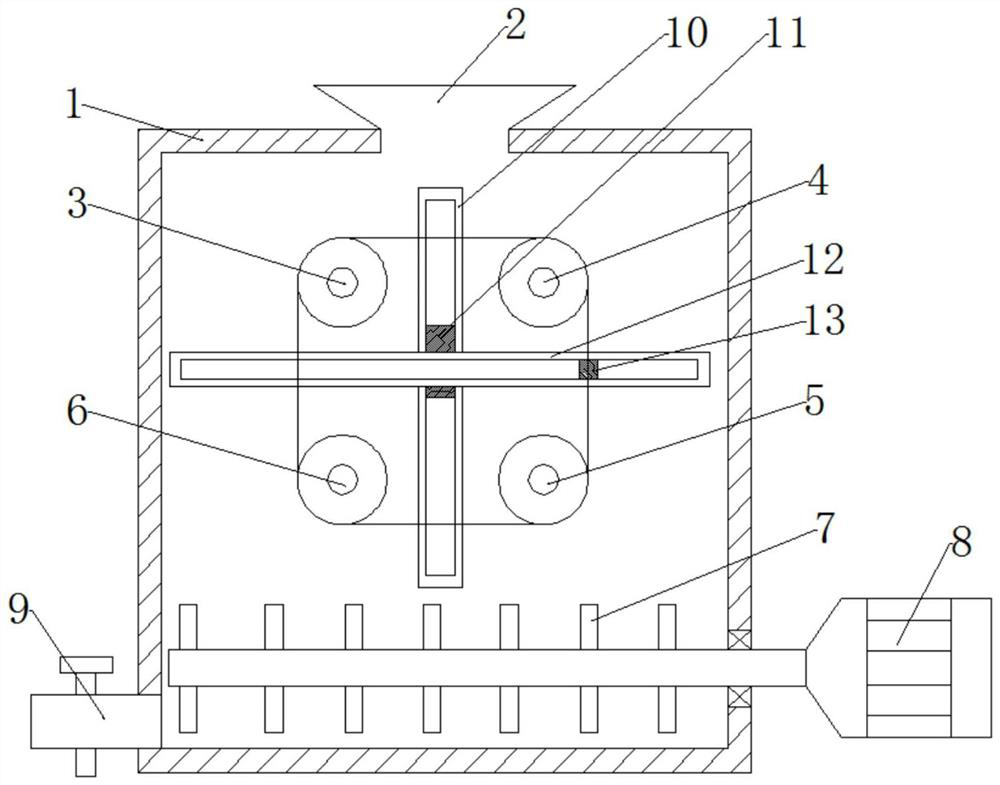

[0026] A feed crushing and stirring device, comprising a tank body, the tank body is provided with a material inlet and a material outlet, and the lower part of the material inlet is provided with a first transmission shaft, a second transmission shaft at the same height, the first transmission shaft, The second transmission shaft is equipped with crushing rollers, the first transmission shaft is also provided with a third transmission shaft at different heights, and the same side of the first transmission shaft, the second transmission shaft, and the third transmission shaft is equipped with a driven wheel , the driven wheels are connected by a transmission chain; the side wall of the tank is also provided with a rail frame along the vertical direction, and the rail frame is embedded with a first slider that can slide in the guide rail of the rail frame, and the first slider is connected with a cleaning A cleaning frame is provided on one side of the cleaning frame, and a groo...

Embodiment 2

[0028] On the basis of Embodiment 1, a fourth transmission shaft is provided on one side of the third transmission shaft, and crushing rollers are sleeved on both the third transmission shaft and the fourth transmission shaft. By setting the fourth transmission shaft, and then setting crushing rollers with matching sizes on the third transmission shaft and the fourth transmission shaft, the feed is further crushed, the crushing efficiency of the feed is improved, and the quality of the feed raw materials is strengthened. Shatter effect.

Embodiment 3

[0030] Based on the above embodiments, the first transmission shaft, the second transmission shaft, the third transmission shaft and the fourth transmission shaft are distributed in a rectangular shape. By setting four sets of transmission shafts in a rectangular distribution, the internal space of the tank is more evenly distributed, and the feed that has not been well crushed by the upper crushing roller can be formed more excellent crushing, which improves the overall crushing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com