Molding machine for factories

A technology of molding machines and factories, applied in the parts of molding machines, casting equipment, manufacturing tools, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

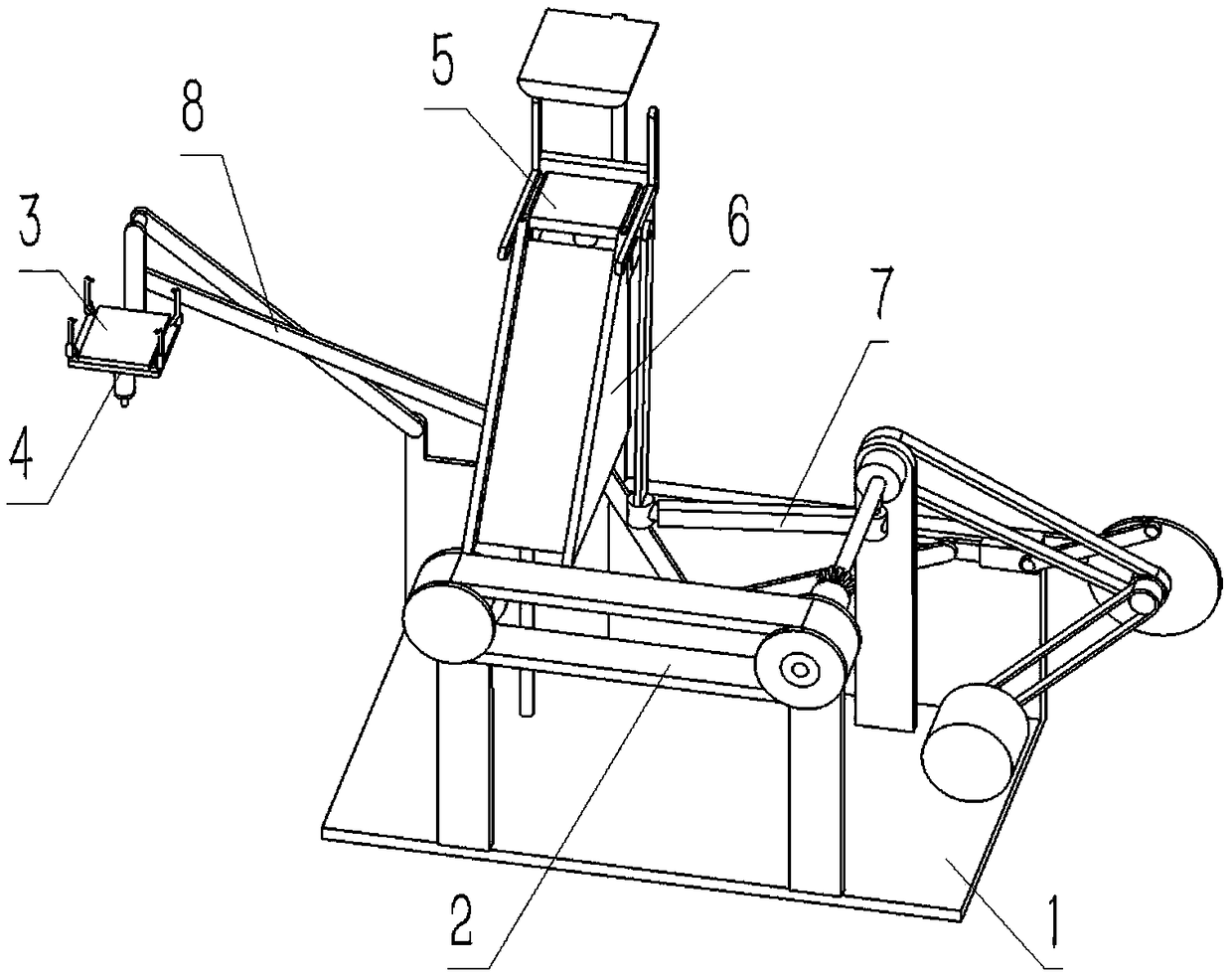

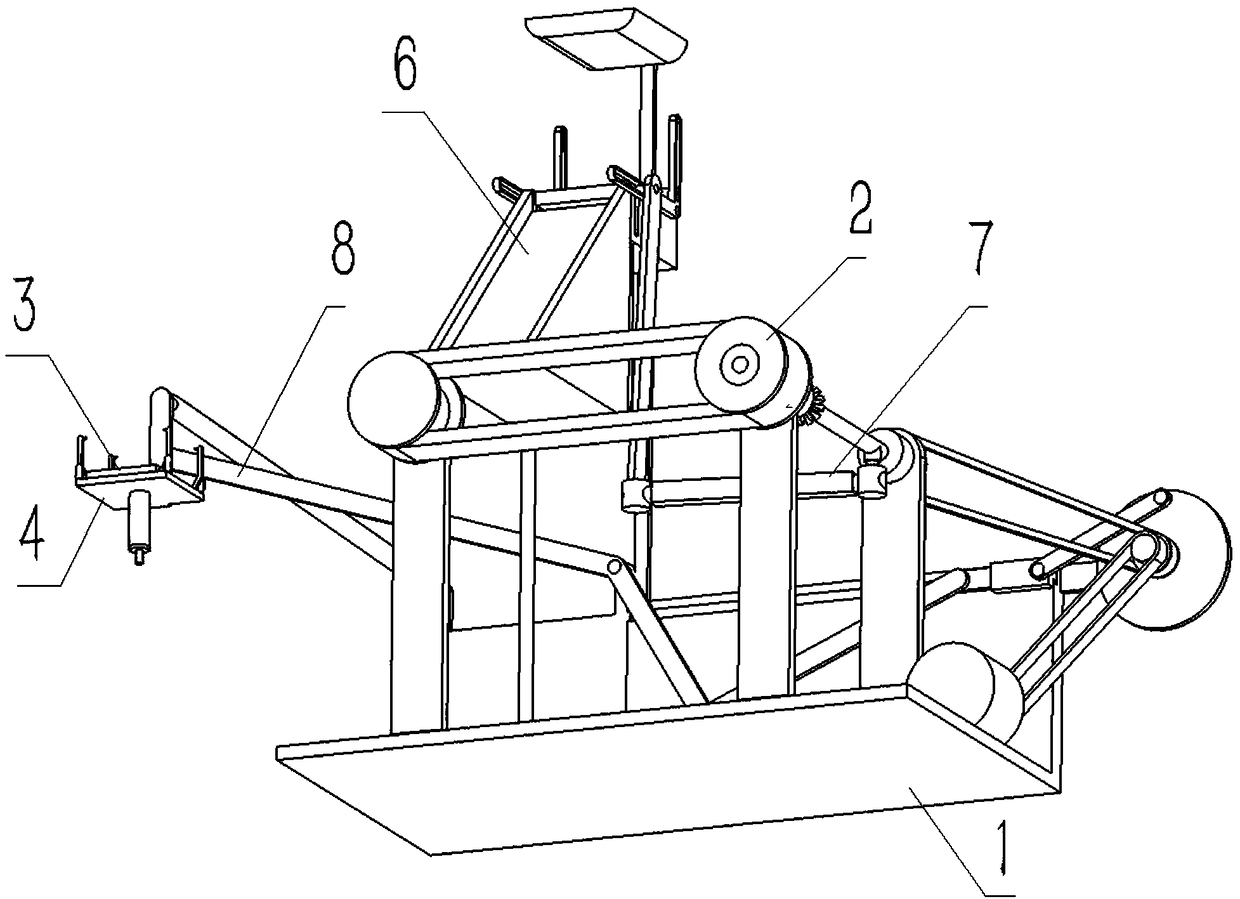

[0039] Combine below Figure 1-19 Describe this embodiment, a factory-used molding machine, including an underframe assembly 1, a conveyor belt 2, a model fixing plate 3, a model cover plate 4, a film lifter 5, a slideway 6, a sliding link 7 and a transmission link 8. The conveyor belt 2 is fixedly connected to the front end of the chassis assembly 1, the model fixing plate 3 is connected to the right end of the chassis assembly 1, the model fixing plate 3 is slidably connected to the middle end of the model sleeve plate 4, and the film lifter 5 is fixedly connected to the middle end of the upper end surface of the chassis assembly 1, the upper end of the slideway 6 is fixedly connected to the film lifter 5, the left end of the sliding link 7 is fixedly connected to the film lifter 5, and the right end of the slide link 7 Slidingly connected to the right end of the upper end surface of the underframe assembly 1, the left end of the transmission link 8 is hinged on the model fi...

specific Embodiment approach 2

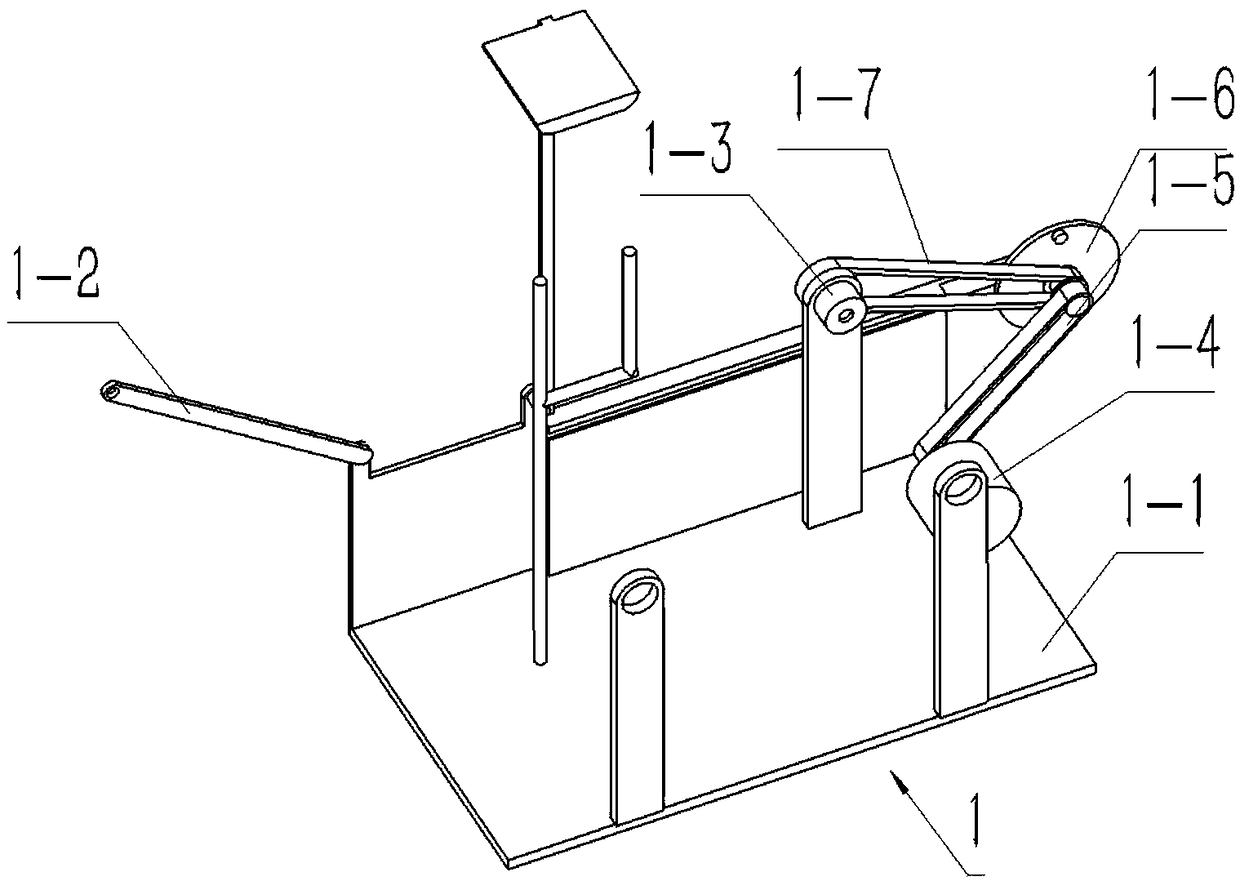

[0040] Combine below Figure 1-19 Describe this embodiment, this embodiment will further explain the first embodiment, the chassis assembly 1 includes a bottom plate 1-1, a left connecting rod 1-2, a gear sleeve rod 1-3, a motor 1-4, an input synchronous Belt 1-5, rotatable cam 1-6, transmission timing belt 1-7, bracket Ⅰ1-8, bracket Ⅱ1-9, back plate 1-10, right support rod 1-11, trapezoidal chute 1-12, Rear support rod 1-13, upper limit boss 1-14, hinged terminal I1-15, hinged terminal II1-16 and mid-end bracket 1-17, gear sleeve rod 1-3 including gear sleeve rod body 1- 3-1. The sliding hole 1-3-2 of the gear sleeve rod and a plurality of internal teeth Ⅰ1-3-3, the inner end of the gear sleeve rod body 1-3-1 is hollowed out, and the sliding hole 1-3-2 of the gear sleeve rod is set At the front end of the gear sleeve rod body 1-3-1, a plurality of internal teeth I1-3-3 are uniformly arranged on the front end of the inner wall of the gear sleeve rod body 1-3-1; the rotatable ...

specific Embodiment approach 3

[0042] Combine below Figure 1-19 Describe this embodiment, this embodiment will further explain the second embodiment, the conveyor belt 2 includes a conveyor belt body 2-1, a left roller 2-2, a right roller 2-3 and a fixed shaft 2-4 , the fixed shaft 2-4 includes a fixed shaft body 2-4-1, an inner sliding hole 2-4-2 and a plurality of internal teeth II 2-4-3, and the inner sliding hole 2-4-2 is arranged on the fixed shaft body 2-4-2. At the inner end of 4-1, a plurality of internal teeth II 2-4-3 are evenly arranged on the rear end of the fixed shaft body 2-4-1, and the front end of the fixed shaft body 2-4-1 is fixedly connected to the right side roller 2- 3, the left and right ends of the conveyor belt body 2-1 are connected to the left roller 2-2 and the right roller 2-3 with interference fit respectively, and the left roller 2-2 is rotatably connected to the bracket II 1-9 , the body of the fixed shaft 2-4-1 is rotatably connected to the bracket I 1-8;

[0043] The lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com