Accurate control production technology for automobile airbag cover

An airbag and precise technology, applied in the field of manufacturing, can solve the problem that the thickness accuracy of the mold cavity cannot meet the requirements, affect the relative position accuracy of the mold, and affect the service life of the mold, so as to achieve controllable production process, accurate adjustment process, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

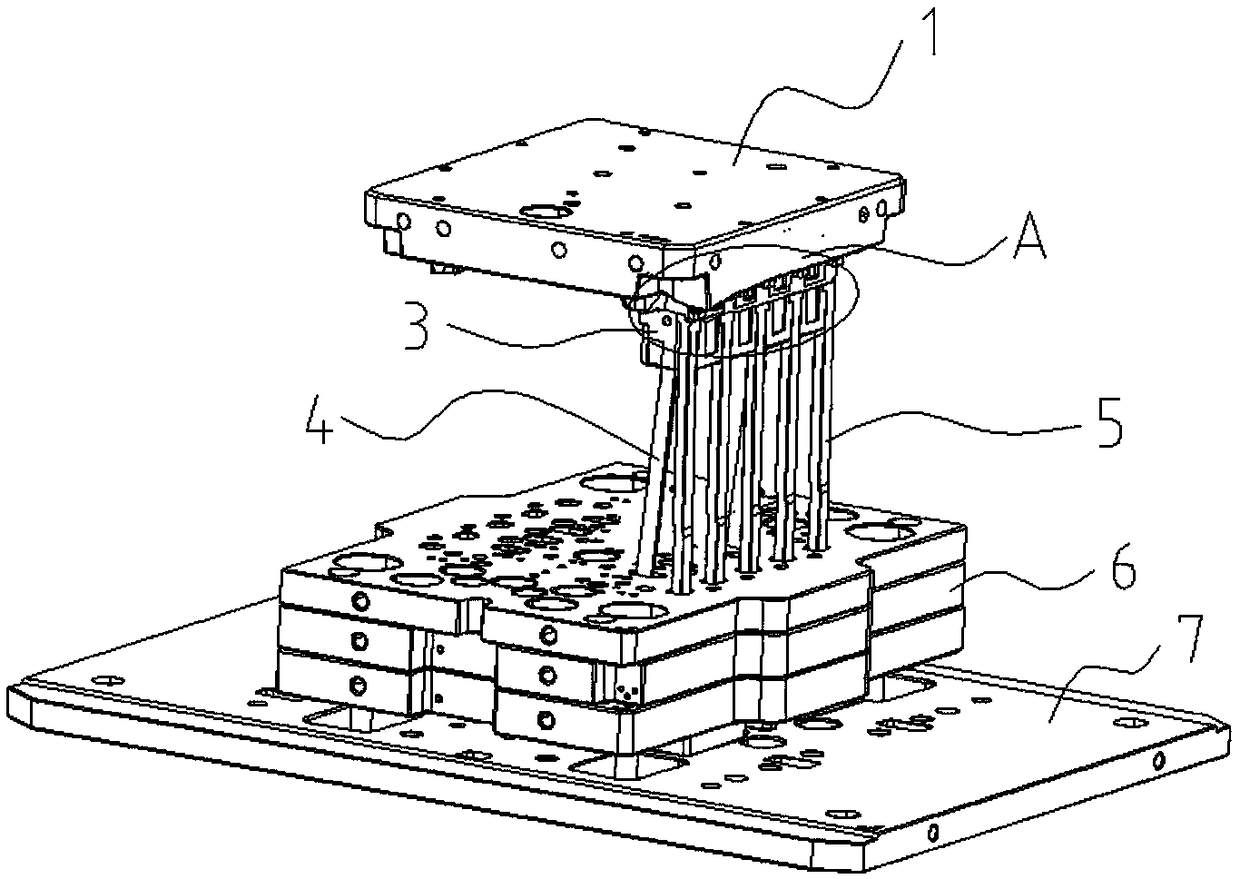

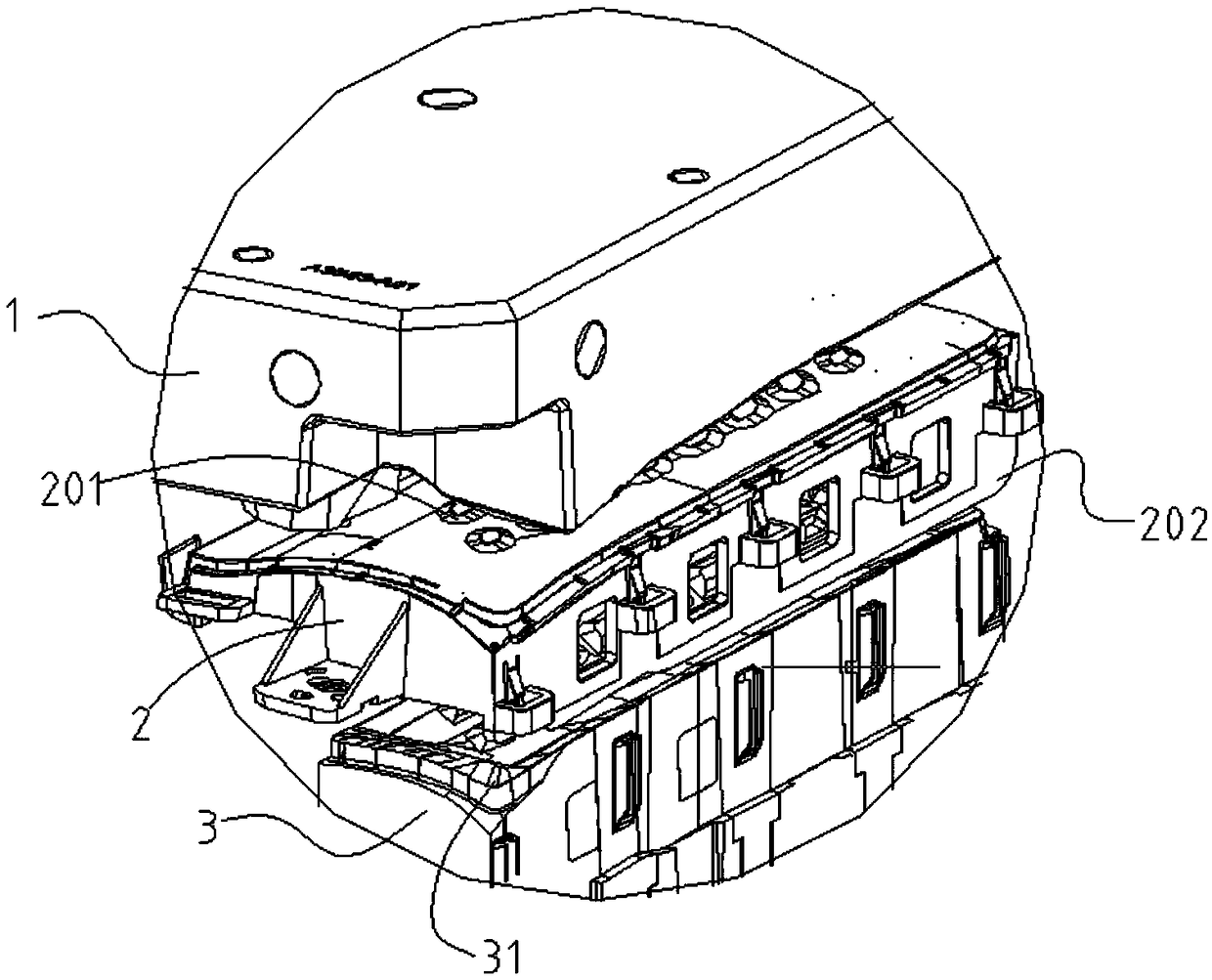

[0055] In order to produce an airbag cover applied to the rear seat of a car, the Figure 4 Shown is an airbag cover mold with increased precision, the airbag cover mold comprising:

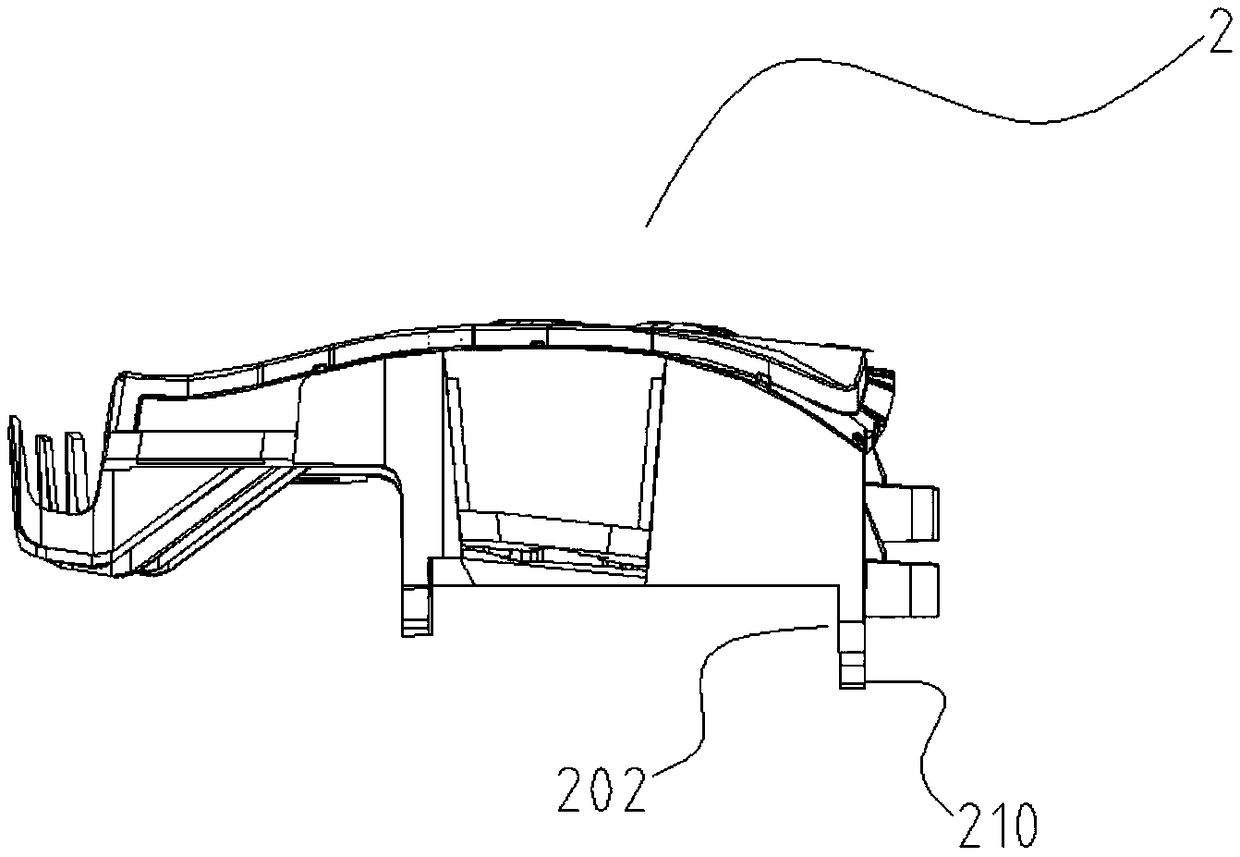

[0056] The fixed mold insert 1 and the movable mold insert 3, the fixed mold insert 1 and the movable mold insert 3 are relatively free to approach and leave, and form a mold cavity when the mold is closed, and the mold cavity is used to shape the rubber material , the airbag cover product 2 is obtained; the shape and dimension accuracy of the mold cavity after mold closing controls the shape, size and precision of the airbag cover product 2;

[0057] The inner surface of the mold cavity is provided with skin texture, which is used to form skin texture on the surface of the airbag cover product 2 after injection molding;

[0058] The inner surface of the mold cavity is also provided with a blasting groove, which is used to form a preset weak portion on the outer surface of the air bag cover prod...

Embodiment 2

[0074] A kind of precise control technology of automobile air bag cover, adopts the air bag cover mold that embodiment 1 provides, with reference to Figure 7 , its specific process steps are as follows:

[0075] 1) Machining mold components (including fixed mold insert 1, movable mold insert 3, inclined push piece group 4, straight push piece set 5, thimble plate 6, bottom plate 7, and adjustment backing plate 8) according to the design size, so that the mold The dimensions of the components meet the tolerance requirements;

[0076] 2) The first grinding and matching; said grinding and matching refers to the use of grinding machine fine grinding, oil stone grinding, grinding paste grinding, etc., to make the cooperation of the punch and die in each mold part, the cooperation of the guide post and the guide sleeve Wait for the required cooperation relationship to be achieved;

[0077] 3) Assemble the mold components into an airbag cover mold, fix and adjust the backing plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com