Intelligent burdening method and device

An intelligent batching and formula technology, applied in clay preparation devices, chemical instruments and methods, mixing operation control devices, etc., can solve problems such as inaccurate batching, achieve accurate batching, and alleviate the effects of inaccurate batching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

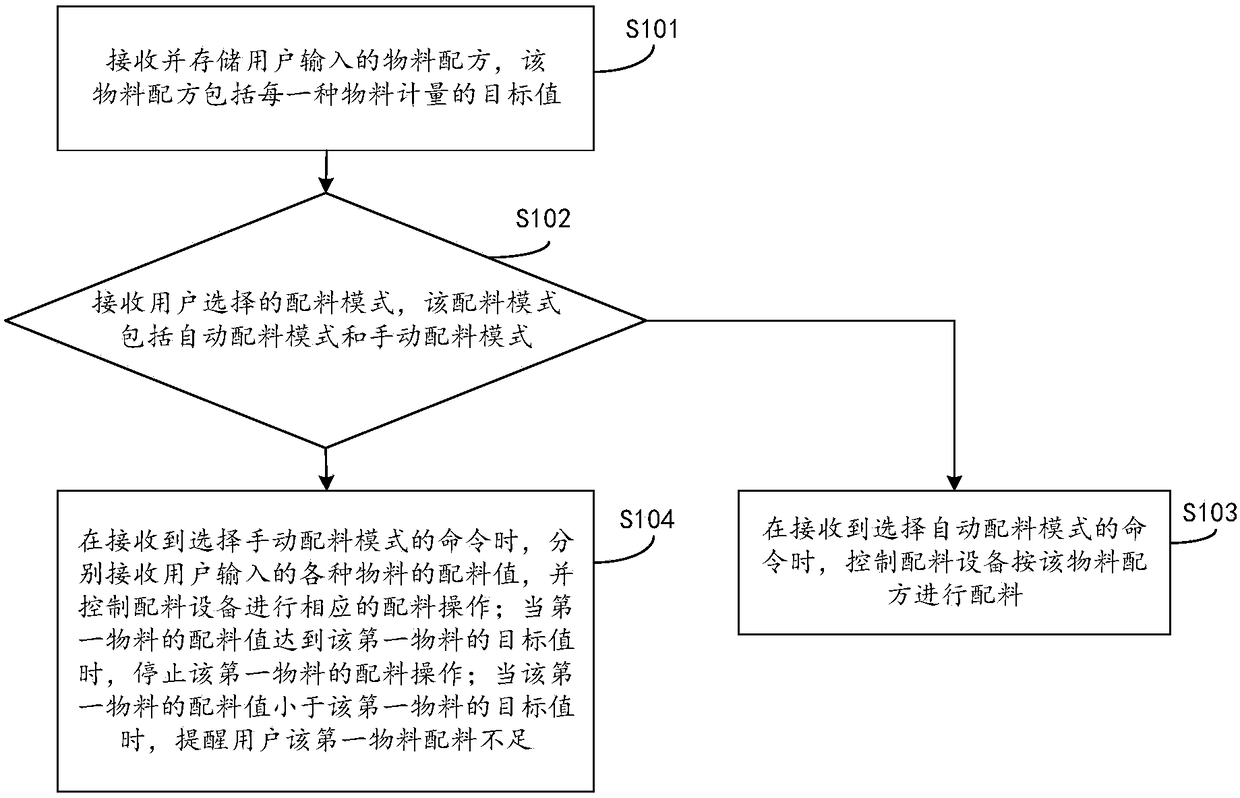

[0030] Such as figure 1 As shown, it is a flow chart of an intelligent batching method provided by an embodiment of the present invention. This method is applied to a mixing station, and is composed of figure 1 Visible, this method comprises the following steps:

[0031] Step S101: Receive and store the material formula input by the user, the material formula includes the target value of each material measurement.

[0032] The user enters the material formula through the human-computer interaction interface, and the material ratio can be freely selected according to the type of product the user needs to produce. Taking concrete as an example, the material can be aggregate, cement, water, etc., and the aggregate can be sand , small stone, medium stone and large stone in free combination. The user enters the measurement target value of the corresponding material according to the demand of the corresponding material, and the target value is the standard measurement of each mate...

Embodiment 2

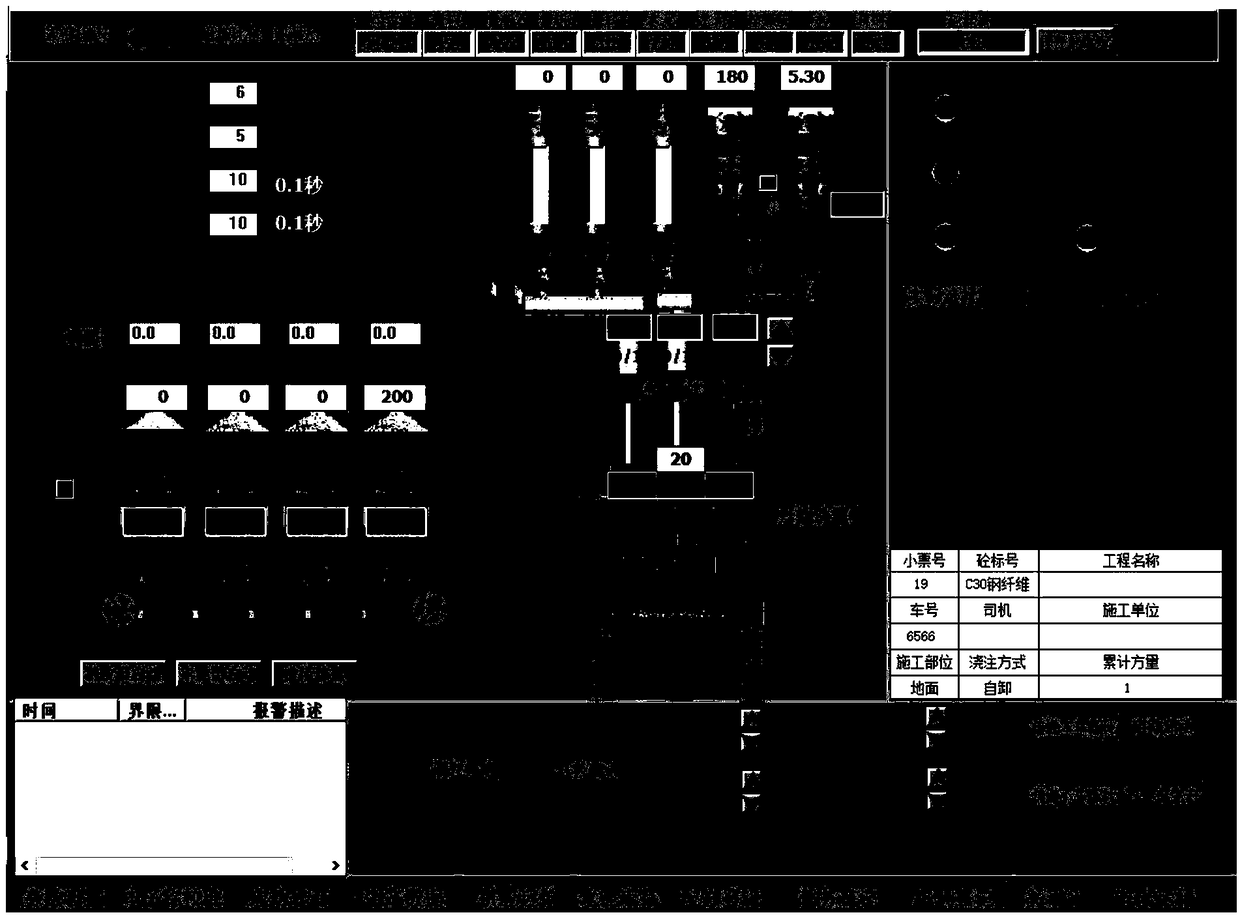

[0045] The embodiment of the present invention is illustrated by taking the practical application of the intelligent batching method in the control system of the mixing station as an example. Such as figure 2 As shown, it is a schematic diagram of an operation interface of an intelligent batching method provided by an embodiment of the present invention. The intelligent batching method is applied to a concrete mixing plant and implemented by programming in C language. exist figure 2 In the illustrated embodiment, the materials include: aggregate 1, aggregate 2, aggregate 3, aggregate 4, cement 1, cement 2, fly ash, water and liquid. There is an input box above each material, and the user can input the ingredient value in the box. If the input value is 0, no ingredient will be added to the material. The material formula entered by the user is displayed at the top of the interface, and the target value of each material is displayed after the material name. If the target val...

Embodiment 3

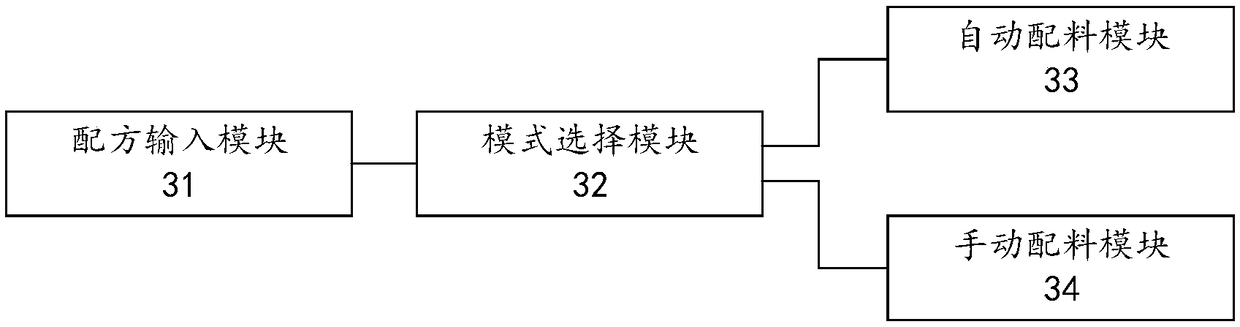

[0048] The embodiment of the present invention also provides an intelligent batching device, such as image 3 As shown, it is a schematic structural diagram of an intelligent batching device provided by an embodiment of the present invention, which is composed of image 3 It can be seen that the device includes a mode selection module 32 , and a formula input module 31 , an automatic batching module 33 and a manual batching module 34 respectively connected to the mode selection module 32 . Among them, the functions of each module are as follows:

[0049] The formula input module 31 is used to receive and store the material formula input by the user, and the material formula includes the target value of each material measurement;

[0050] The mode selection module 32 is used to receive the batching mode selected by the user, and the batching mode includes an automatic batching mode and a manual batching mode;

[0051] The automatic batching module 33 is used to control the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com