Waste paper packaging machine

A waste paper baler, waste paper technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of easy generation of dust, incomplete compression, unfavorable workshop cleaning, etc., to reduce transportation costs, avoid dust escape, and ensure cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

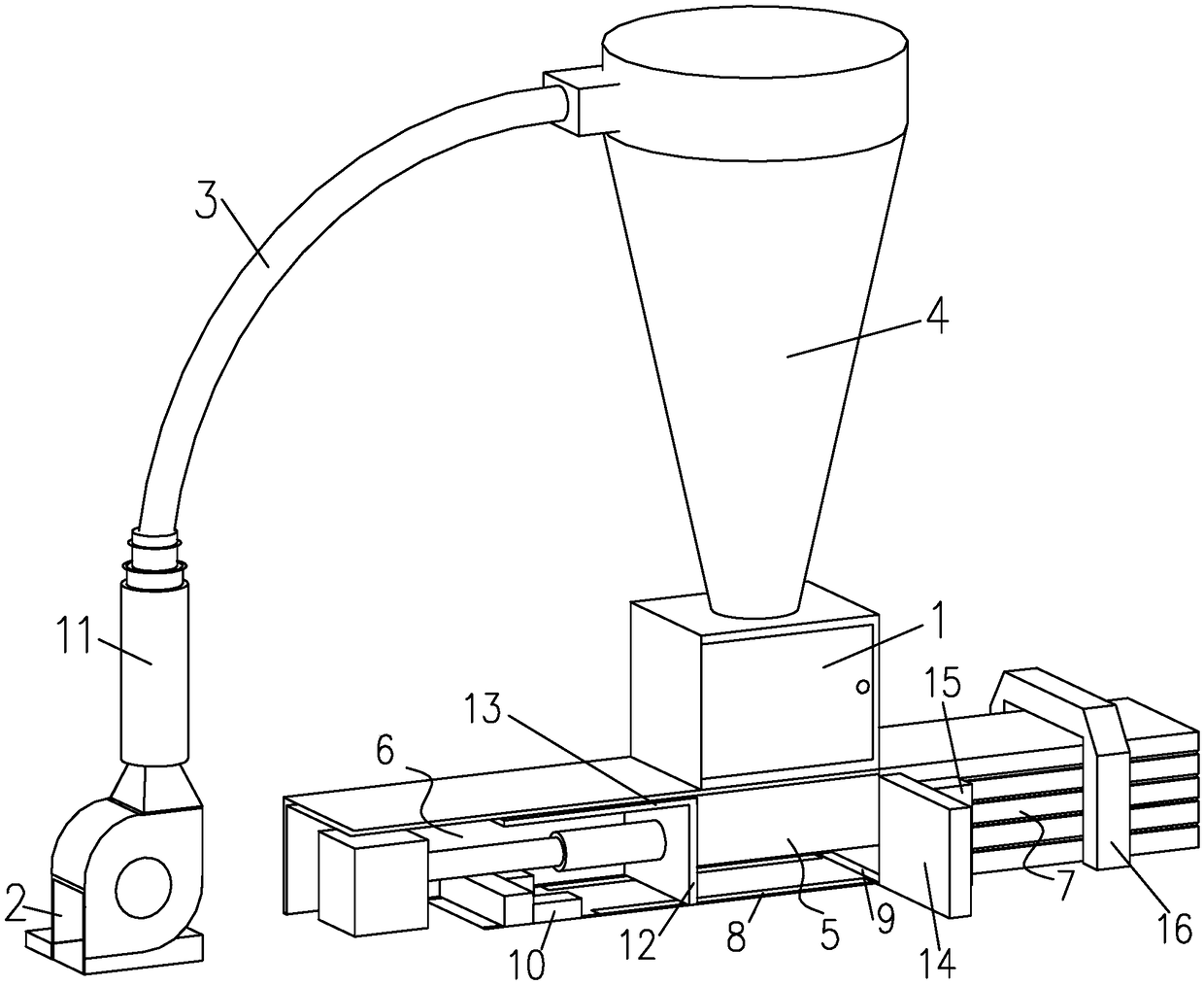

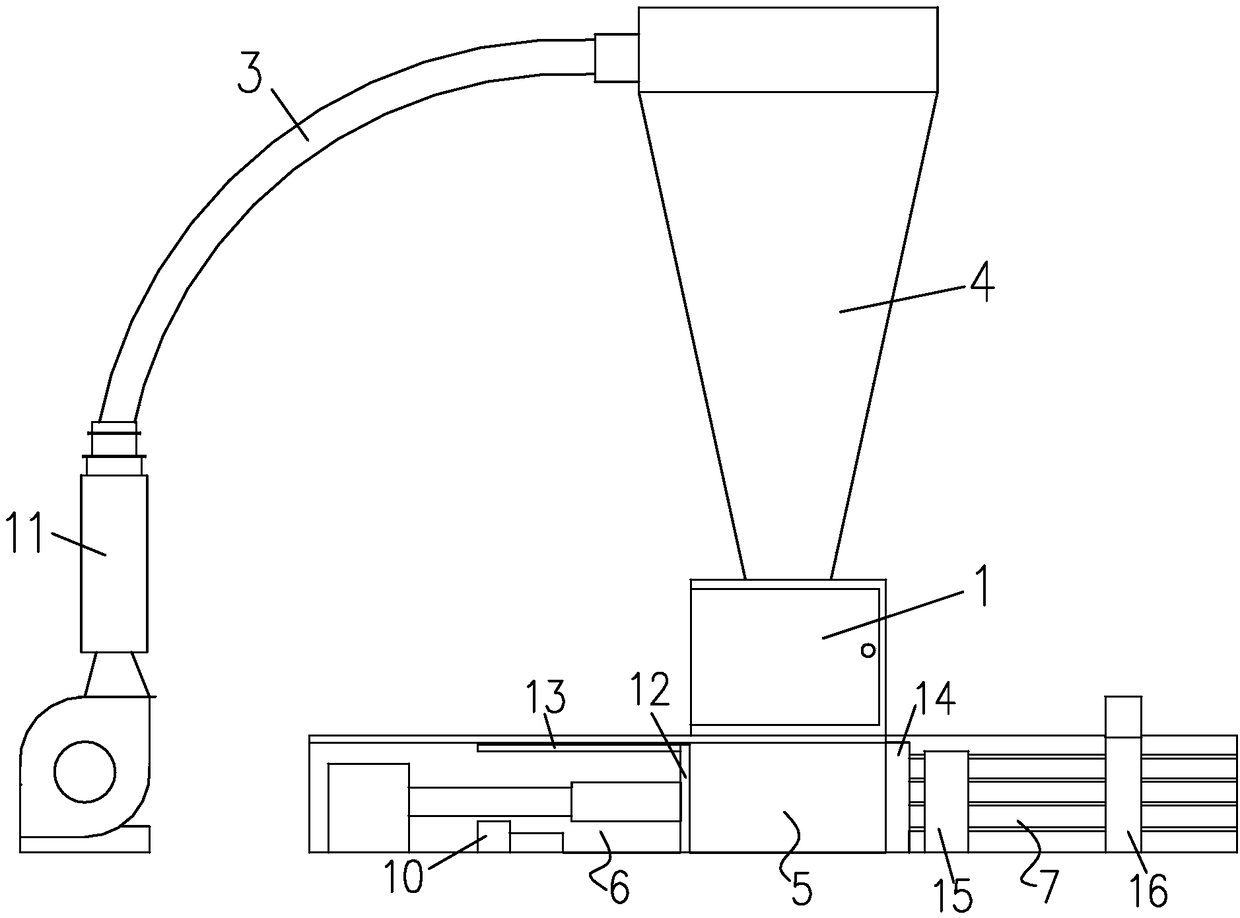

[0020] See attached Figure 1-2 , a waste paper baler according to an embodiment of the present invention, comprising a feed box 1, including a feed box, the inner wall of the feed box 1 is provided with a spray device for spraying water on the waste paper; the feed box 1 is connected with a closed feeding device, which includes a sequentially connected feeding port 2, a feeding pipeline 3, a funnel 4, and a fan for sucking waste paper into the feeding device, and the funnel 4 is vertical placed, the discharge end of the funnel 4 is connected to the feed box 1; a compression chamber 5 is provided below the feed box 1, and tool chambers connected to the compression chamber 5 are respectively provided on both sides of the compression chamber 5 6 and a paper outlet chamber 7; the tool chamber 6 is provided with a propulsion mechanism, the compression chamber 5 is provided with a first guide rail 8 that guides the advancement mechanism, and the connection between the compression c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com