A fully automatic circular screen printing machine

A screen printing machine, fully automatic technology, applied in the direction of screen printing machine, printing machine, rotary printing machine, etc., can solve the problems of slow placement speed, poor position reliability, manual operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

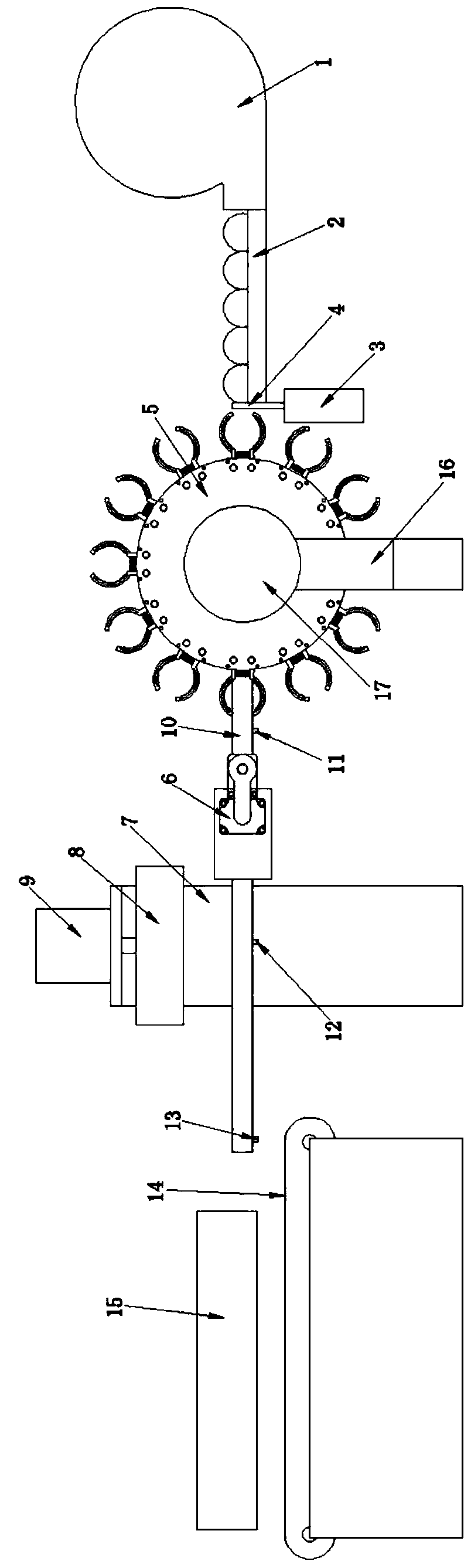

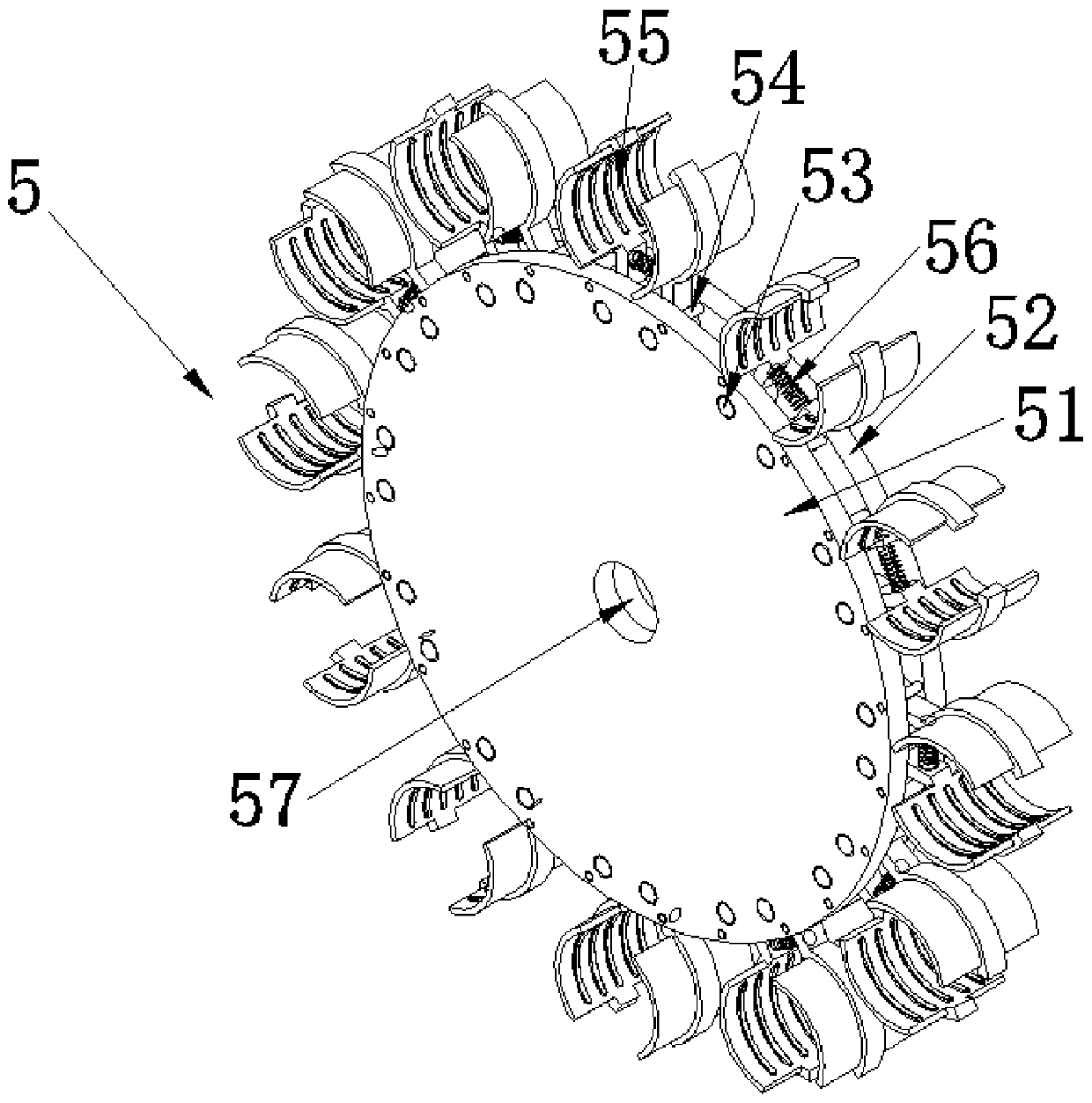

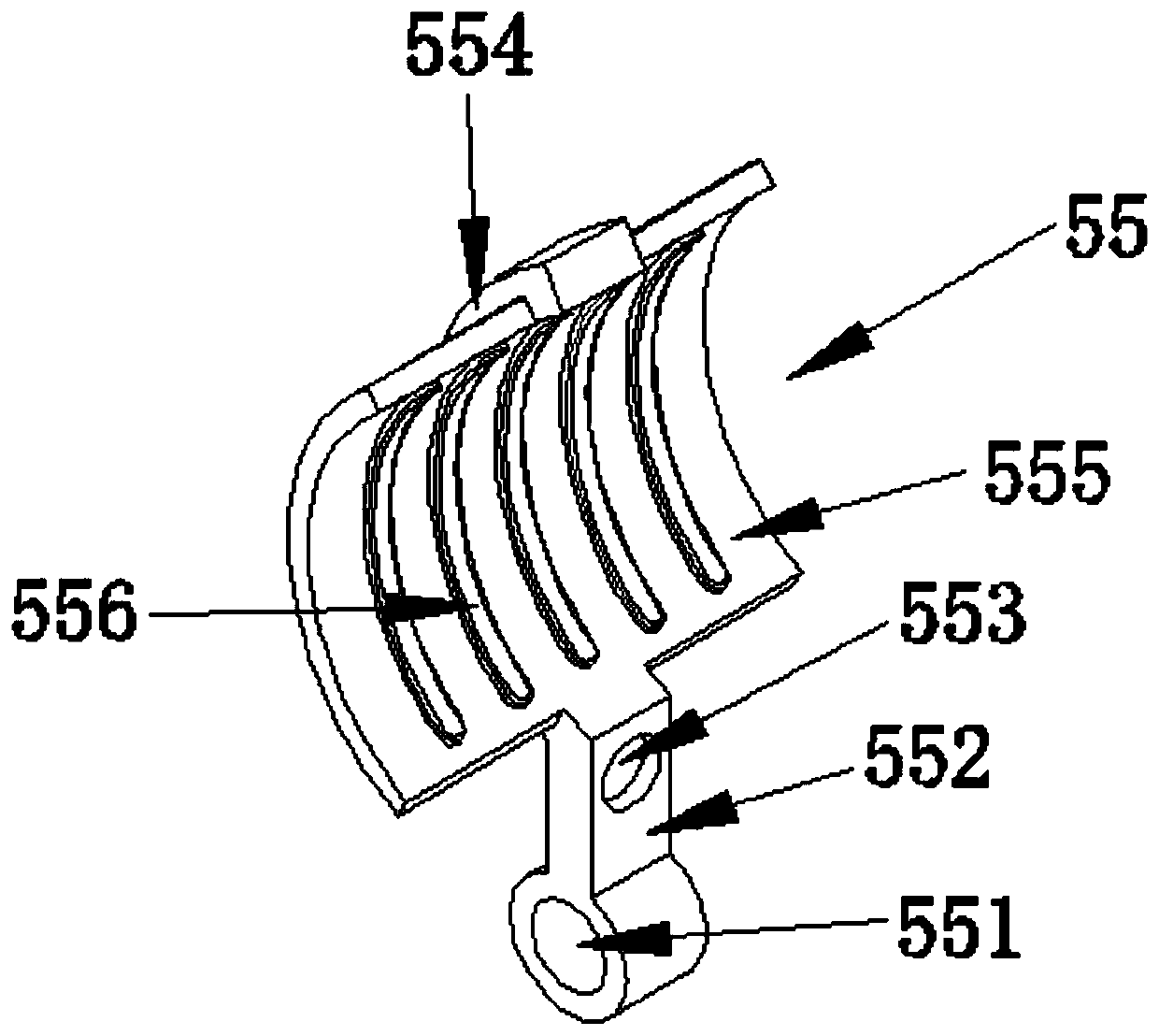

[0016] refer to Figure 1-Figure 5 , a fully automatic circular screen printing machine of the present invention, comprising a vibrating plate 1, a reclaiming manipulator 5, a semi-manipulator 55, a multifunctional device 6, a silk screen mechanism 8, a hydraulic cylinder 9, a motor guide rail 10, a conveyor belt 14 and a drying device 15. The lower end of the vibrating plate 1 is connected with a conveying trough 2, and the retaining cylinder rod 4 of the retaining cylinder 3 blocks one end of the conveying trough 2, and a reclaiming manipulator 5 is arranged between the conveying trough 2 and the motor guide rail 10 , the central hole 57 on the first turntable 51 and the second turntable 52 in the reclaiming manipulator 5 is arranged on the output shaft of the stepper motor 17, and the stepper motor 17 is fixed on the support column 16; The motor guide rail 10 is provided with The multifunctional device 6, the sliding slot 75 on the lower side of the motor slider 61 of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com