Container leg column installation method

An installation method and container technology, applied in deck loading, transportation and packaging, ship parts, etc., can solve the problems of long construction period and achieve the effect of improving construction safety and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

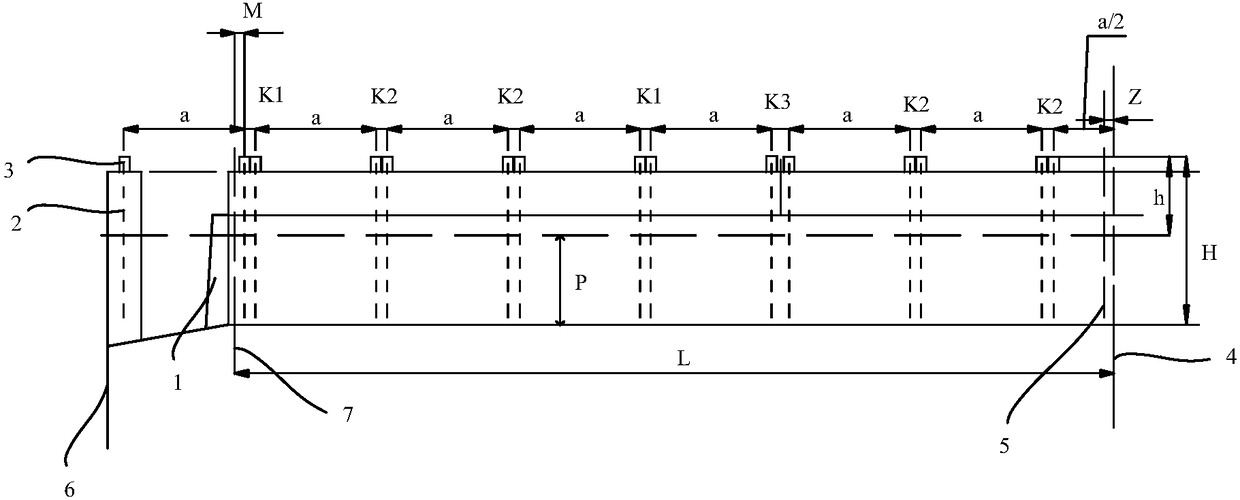

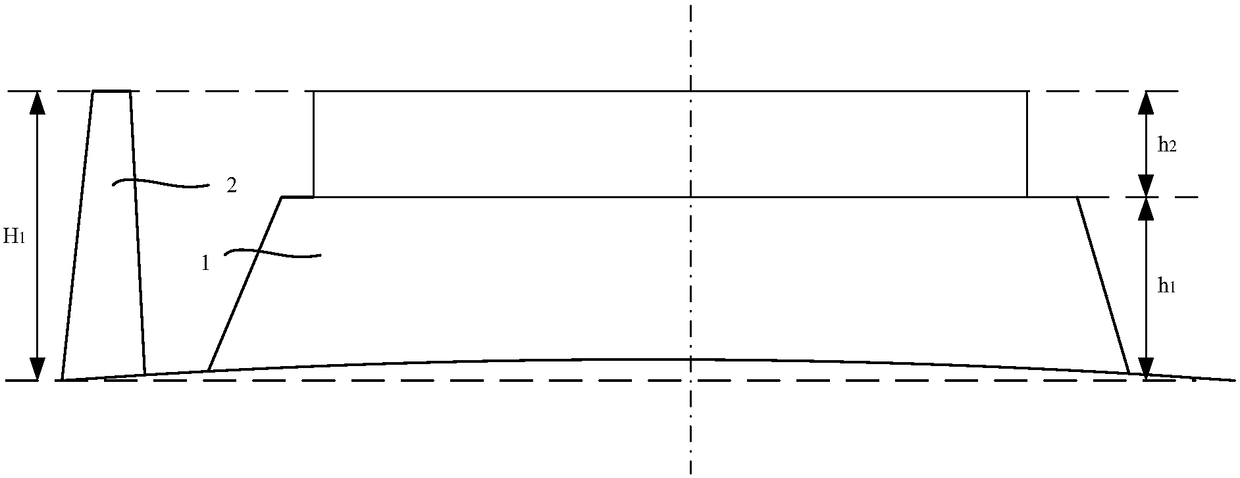

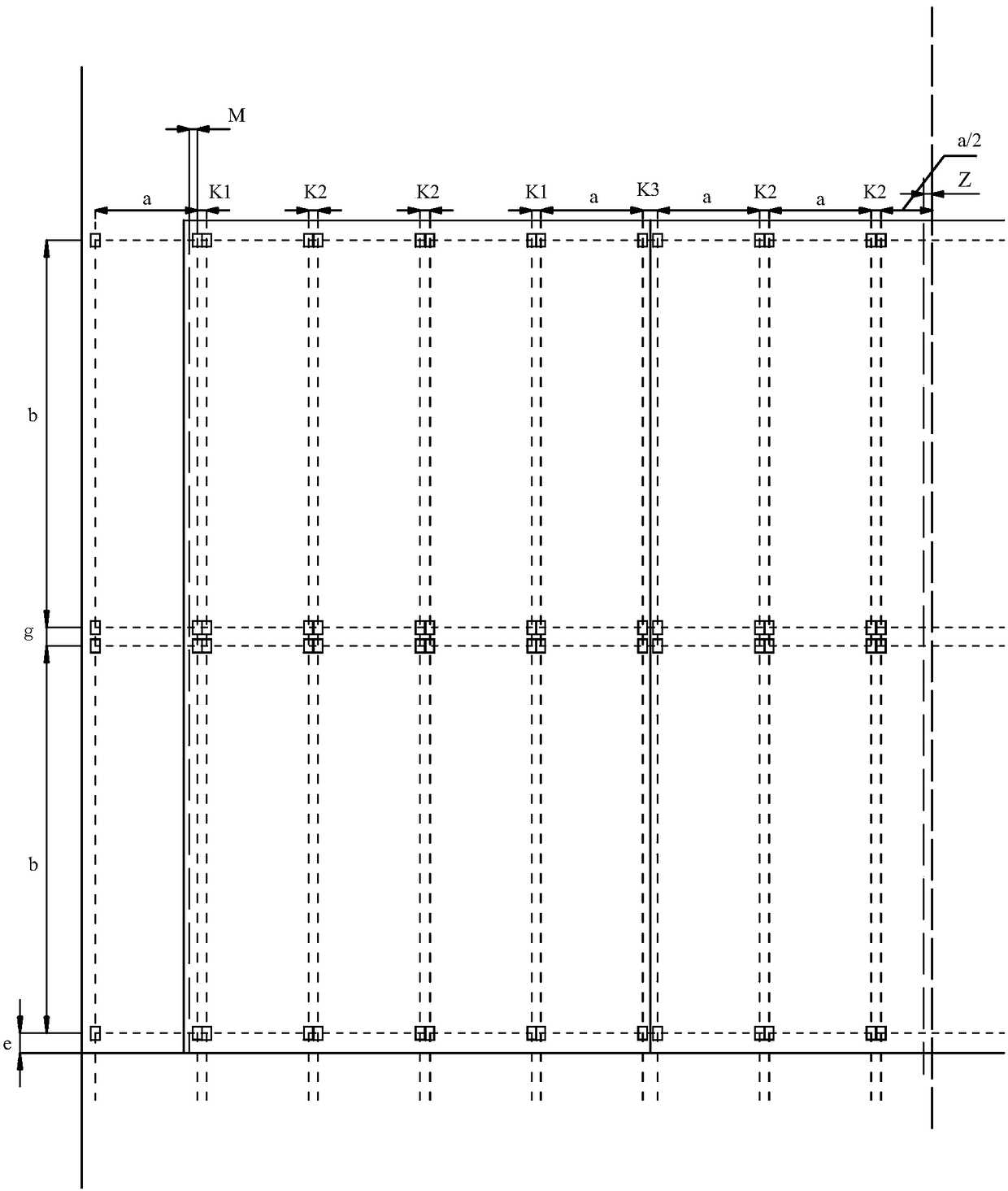

[0042] Such as figure 1 As shown, the container foot column 2 is installed on the outside of the hatch coaming 1, the container box foot 3 is installed on the container box foot column 2, and the container box foot 3 is used to support the container. The installation method of the container foot column of the present embodiment is as follows: Figure 4 shown, including the following steps:

[0043] 101. Determine the deviation between the centerline 4 of the container on the hatch cover and the centerline 5 of the ship, and draw the centerline 4 of the container. The deviation between the centerline 4 of the container placed on the hatch cover and the centerline 5 of the ship is the horizontal projection distance.

[0044] 102. Determine the distance between the container foot centers, and determine the number of containers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com