Large boiler mounting method based on BIM technology

A technology for large boilers and installation methods, applied in data processing applications, instruments, geometric CAD, etc., can solve the problems of long construction period, high construction cost, rework, etc., to achieve simple construction coordination, improve construction quality, and ensure smooth effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0070] This project is applied to Ningxia Baofeng Energy Group Co., Ltd. coke gasification to 600,000 tons / year olefins project power station 9# boiler device. This boiler is a high-temperature and high-pressure coal-fired drum boiler, П-shaped layout, and four-corner tangential combustion method , solid-state slag discharge, balanced ventilation, tight-fitting closed layout, two three-storage rotary air preheaters, and all-steel suspension structure. The maximum continuous evaporation capacity of the boiler is 441t / h.

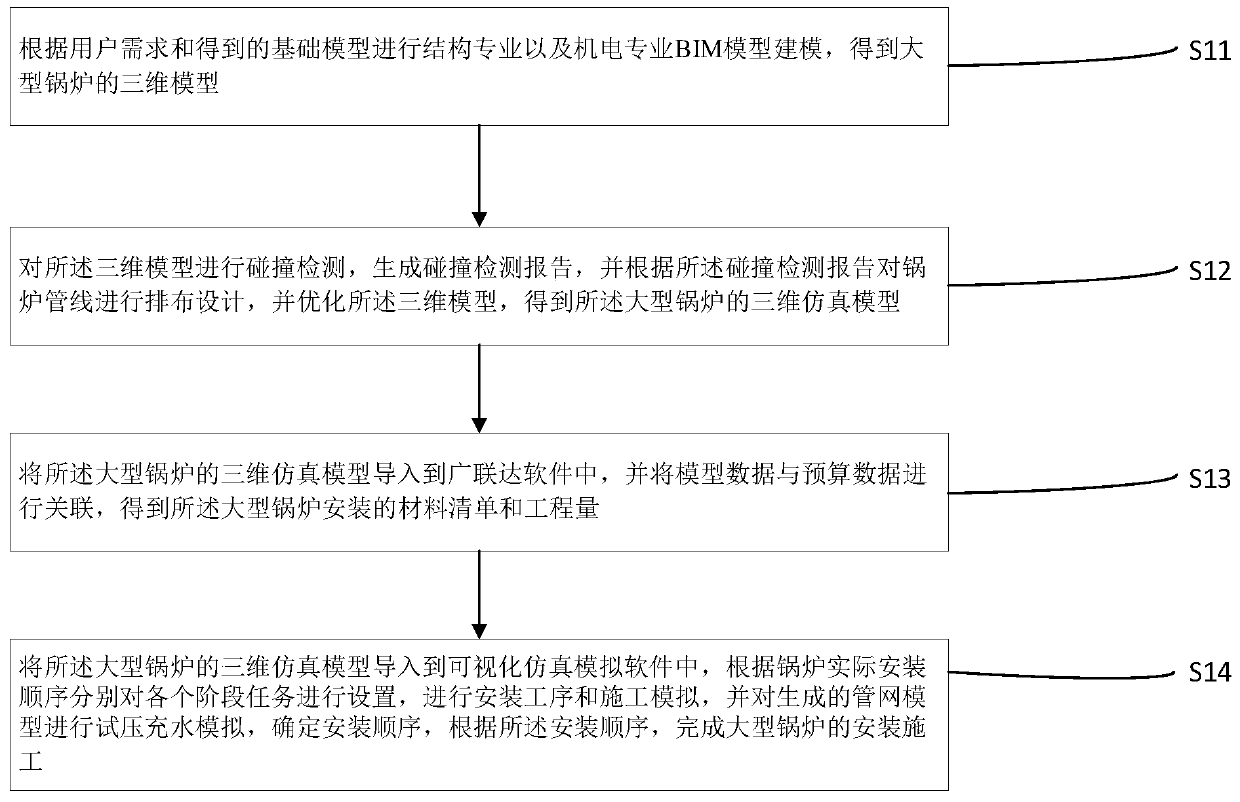

[0071] The specific installation steps include: 1) Carry out structural professional and electromechanical professional BIM model modeling on the basic model of the boiler device to obtain a three-dimensional model of the boiler;

[0072] 2) Carry out collision detection on the three-dimensional model, generate a collision detection report, and carry out layout design to boiler pipelines according to the collision detection report, and optimize the three-dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com