Automatic conveying system and method

A technology of automatic conveying and mobile equipment, applied in the direction of manual conveying devices, transportation and packaging, storage devices, etc., can solve the problems of large labor load, high work intensity, and large labor load for unloading and picking up goods, so as to improve the efficiency of item distribution and Flexibility, reduced labor costs, and the effect of reducing physical labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

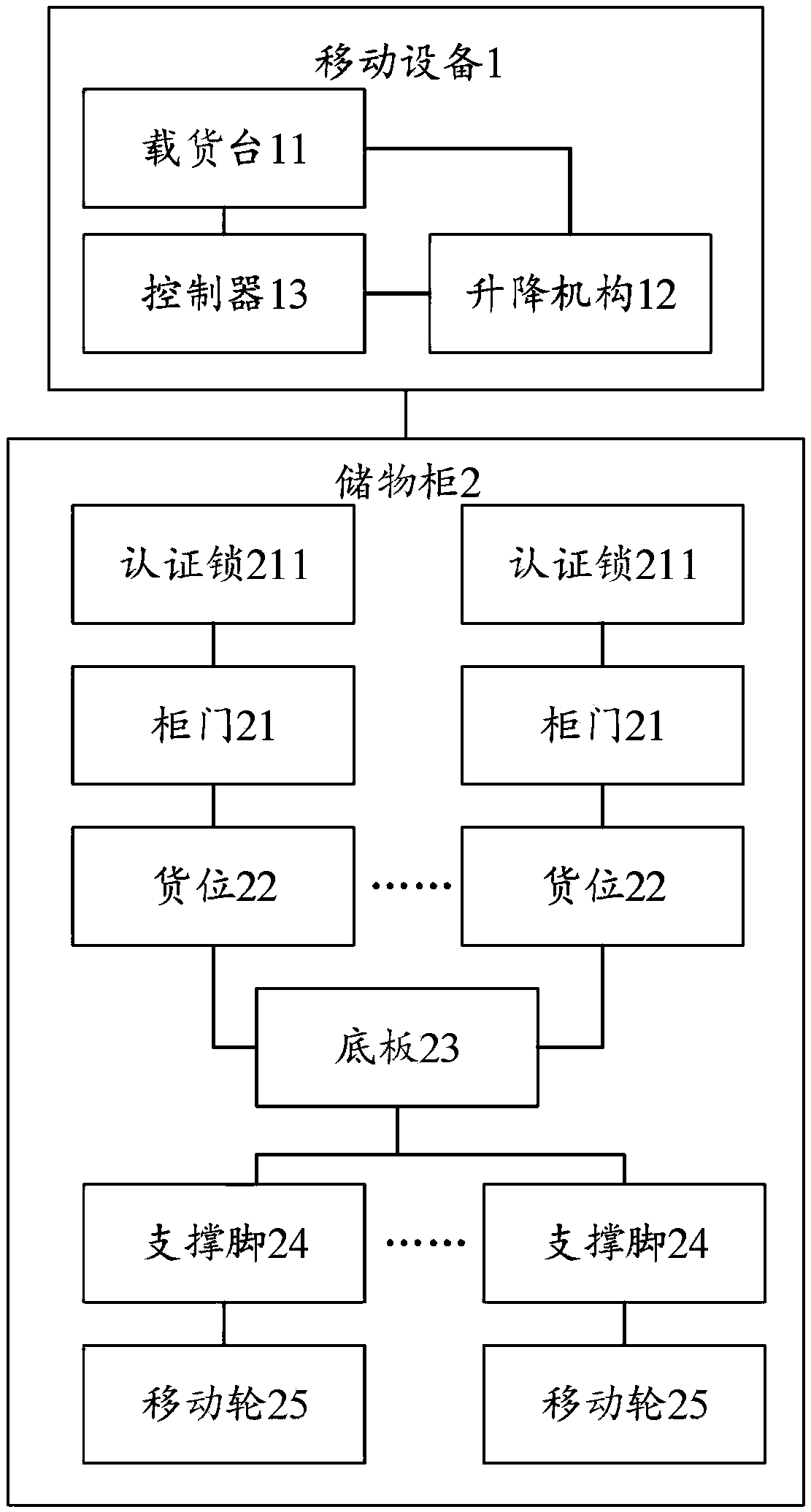

[0072] The first embodiment of the present invention, an automatic conveying system, such as figure 1 As shown, including: locker 2 and mobile device 1;

[0073] The mobile device 1 is provided with a loading platform 11 for carrying several lockers 2, and a controller 13 for controlling the mobile device 1 to move to the corresponding delivery destination according to the delivery route; the mobile device 1 is provided with an adjustable loading platform The lifting mechanism 12 of the height between 11 and the ground;

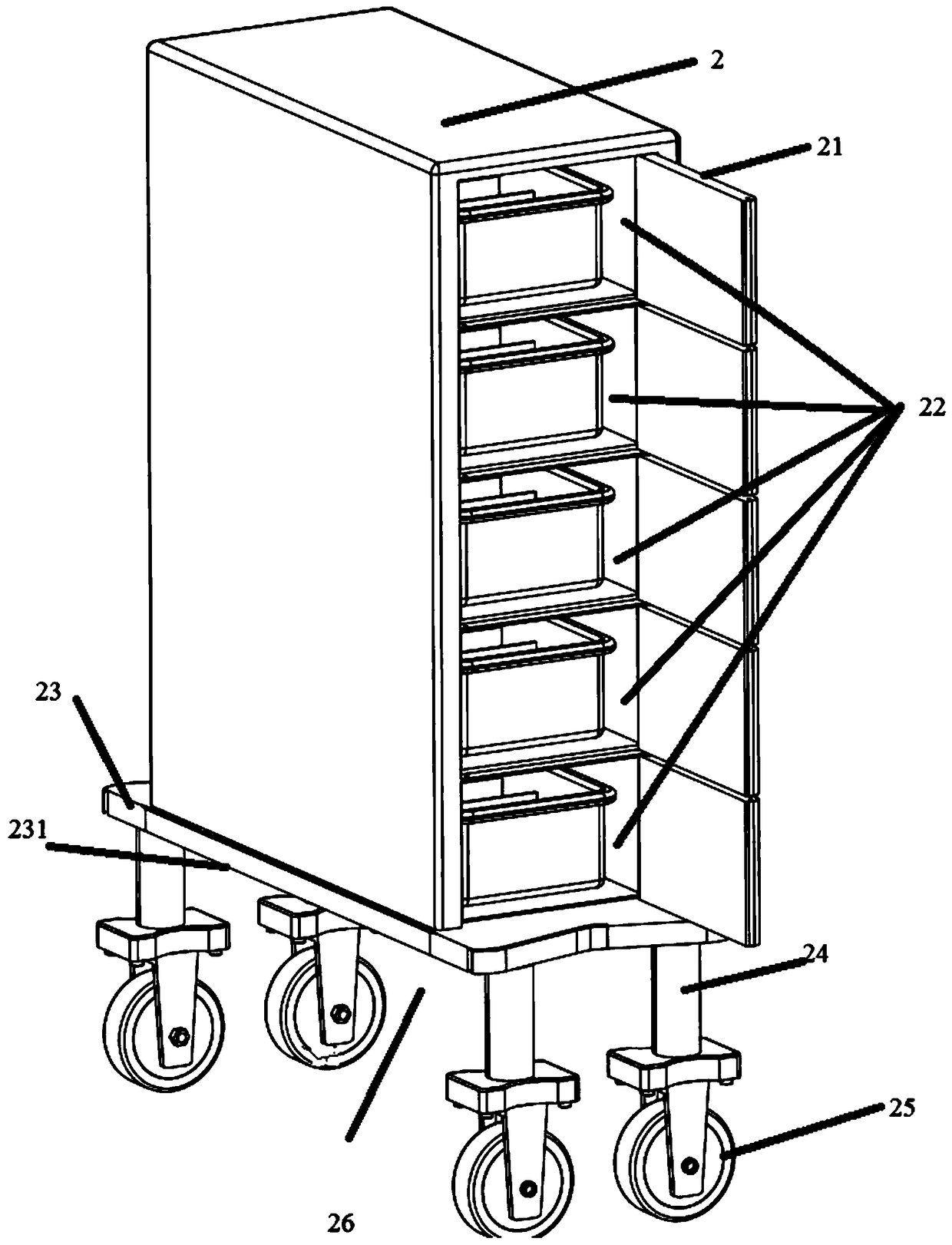

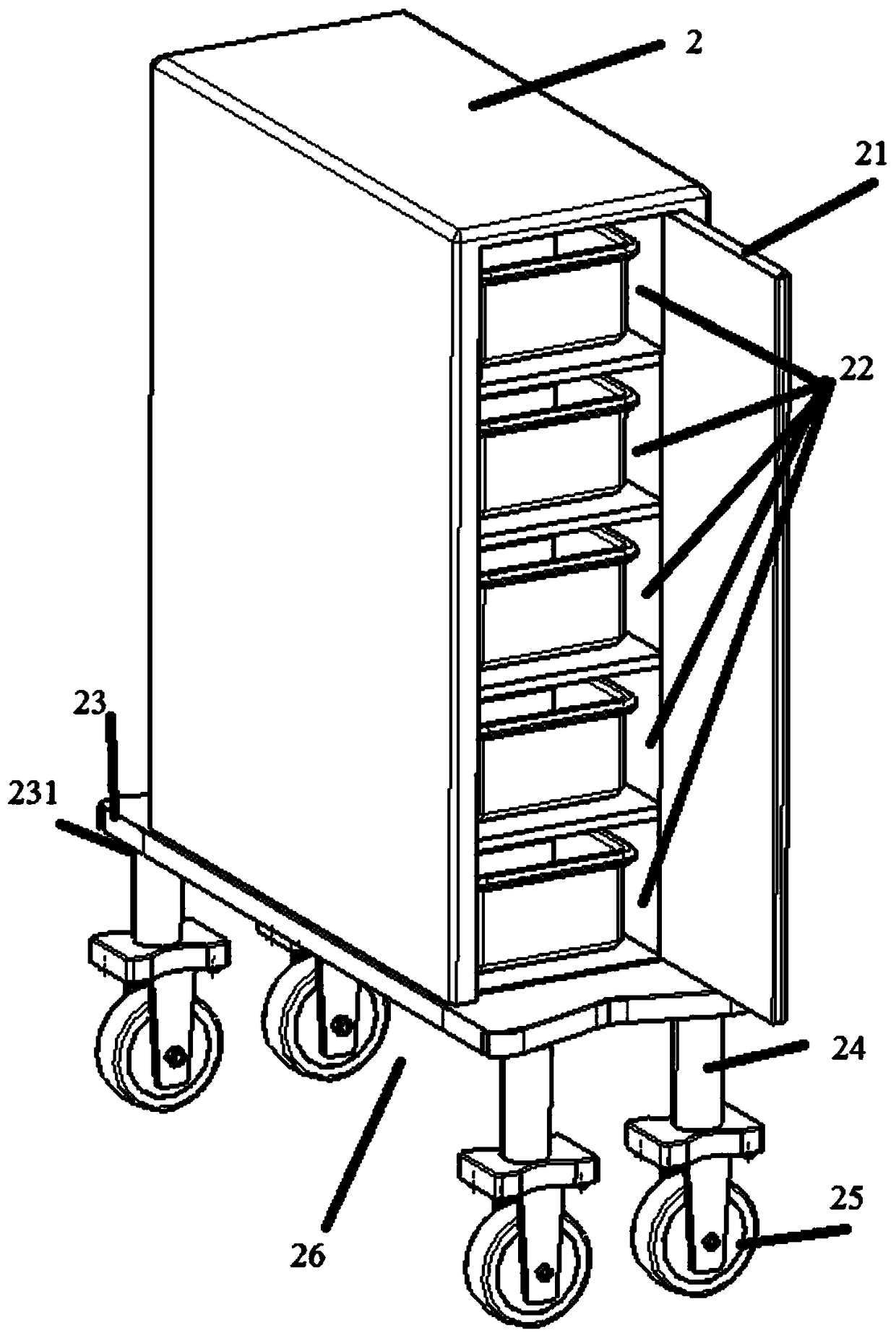

[0074] The locker 2 is provided with a cabinet door 21, which is used to control the authentication lock 211 of the switch state of the cabinet door 21; the locker 2 includes several layers of cargo spaces 22;

[0075] Locker 2 is provided with bottom plate 23, and the bottom edge of bottom plate 23 is provided with several supporting feet 24 relatively, and bottom plate 23 and supporting feet 24 form accommodating space 26, so that loading platform 11 is do...

no. 3 example

[0084] The third embodiment of the present invention, this embodiment is an optimized embodiment of the above-mentioned first or second embodiment, comprising: the mobile device 1 is further provided with an orientation detection component for detecting the orientation information of the accommodation space 26 .

[0085] Specifically, in this embodiment, the mobile device 1 is also provided with an orientation detection component for detecting the orientation information of the storage space 26. The orientation detection component includes but is not limited to an infrared instrument, a camera, and detects the orientation and position of the storage space 26, etc. The location information, so that the mobile device 1 can move to approach the storage space 26 by itself, and dock the loading platform 11 with the storage space 26 to automatically load the locker 2 . The mobile device 1 carries the locker 2 and travels to a delivery destination corresponding to the delivery route a...

no. 4 example

[0087] The fourth embodiment of the present invention, this embodiment is an optimized embodiment of any one of the above-mentioned first to third embodiments, the loading platform 11 includes:

[0088] A supporting surface 111 for carrying several lockers 2;

[0089] Lifting baffles located on the support surface 111;

[0090] The motor used to drive the lifting of the lifting baffle.

[0091] Specifically, in this embodiment, after the mobile device 1 transports the locker 2 to the delivery destination, the motor drives the lifting baffle to descend, so as to facilitate unloading of the locker 2 . After the locker 2 is loaded on the support surface 111 of the loading platform 11, the motor drives the lifting baffle to rise, so that the lifting baffle blocks the locker 2 placed on the support surface 111 during the transportation of the mobile device 1, Avoid the sliding phenomenon of the locker 2 due to uneven ground or emergency stop, and improve the safety of item transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com