Angling device for climbing belt conveyor

A technology of corner mechanism and belt conveyor, which is applied in the direction of conveyor, transportation and packaging, etc., which can solve the problem of affecting the service life and efficiency of climbing belt conveyor, deformation and damage of the external shell supporting the conveyor belt, and affecting the service life of climbing belt conveyor and other problems, to achieve the effect of improving the flexibility of use, strong flexibility of use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

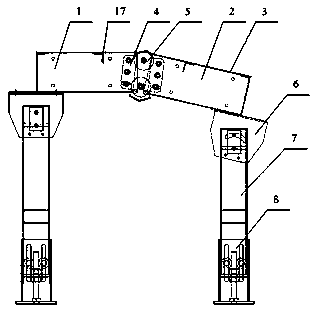

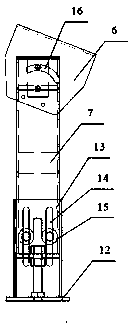

[0022] Such as figure 1 , figure 2 It shows an embodiment of a corner mechanism for a climbing belt conveyor of the present invention, including

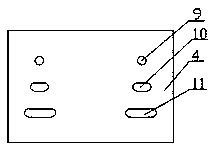

[0023] A casing group, the casing group includes a first casing 1 placed horizontally and a second casing 2 placed obliquely, the first casing 1 and the second casing 2 are both U-shaped structures, and the first casing 1 and the opening of the second shell 2 are set downwards, the lower end faces of the first shell 1 and the second shell 2 are provided with an inwardly bent bottom plate 3, between the first shell 1 and the second shell 2 There are two connecting plates 4 arranged in tandem;

[0024] A driving group, the driving group includes a driving roller group placed between two connecting plates 4, the driving roller group includes two driving rollers 5 arranged one above the other, and the two ends of the driving rollers 5 are respectively set through the connecting plate 4;

[0025] An adjustment seat group, the adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com