Variable-angle baffle assembly

An angle and variable technology, applied in railway car body parts, cargo support/secured parts, transportation and packaging, etc., can solve the problems of affecting transportation costs, transportation waste, etc., and achieve a simple structure design method, convenient maintenance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

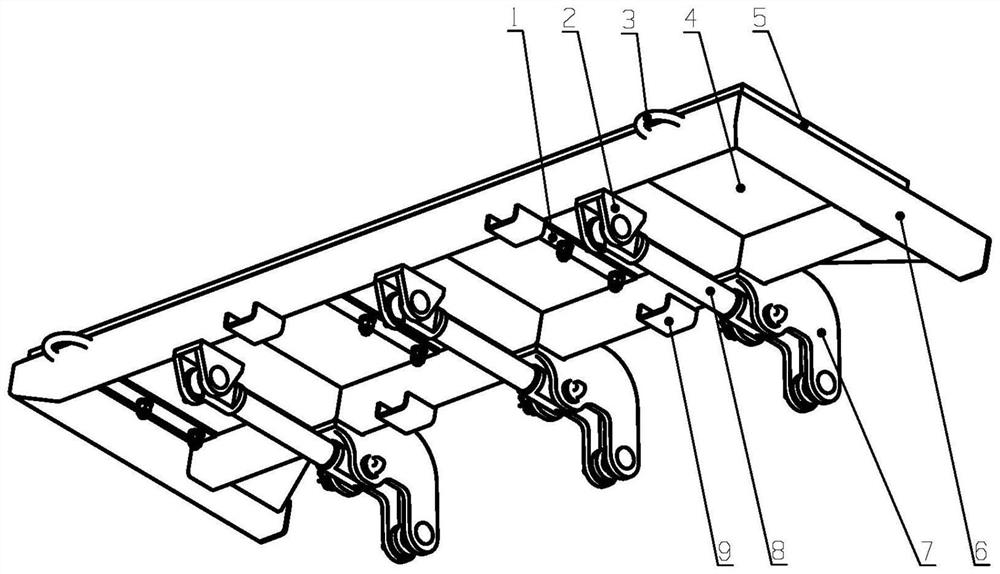

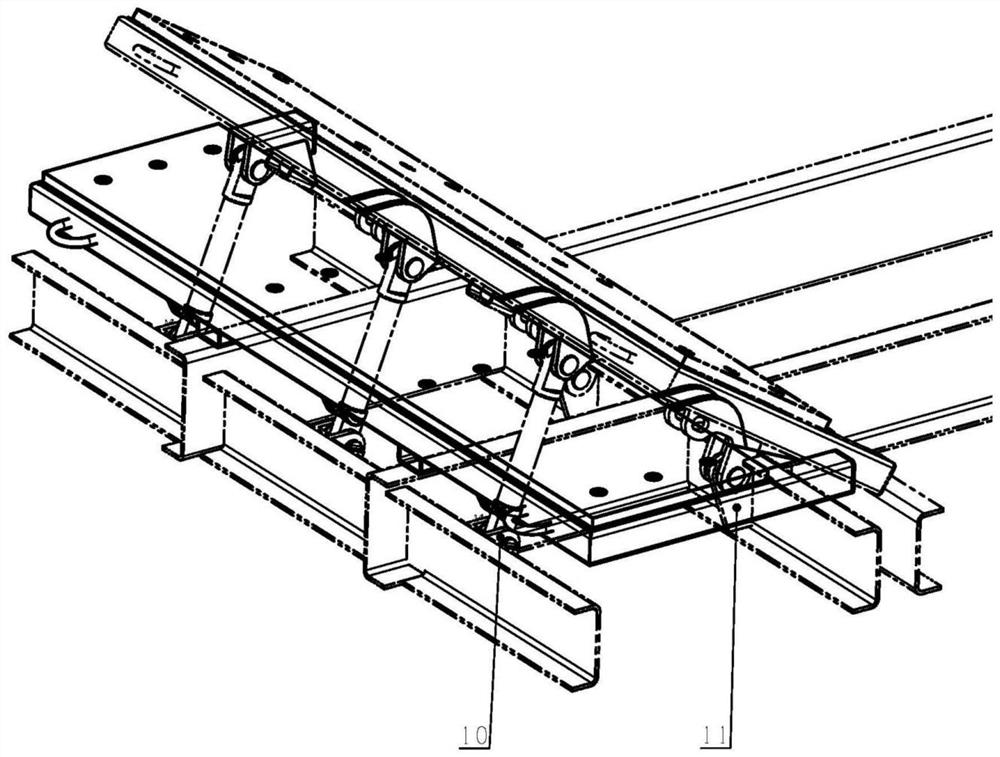

[0036] This embodiment is basically as Figure 1 to Figure 5 As shown: this embodiment provides a variable-angle baffle composition, which can be applied to the requirements of loading coil steel of various diameters and various forms of steel, plate, steel bar, etc., which includes frame composition 6, baffle composition , the support base 2 and at least one strut form 8, specifically, one side of the frame composition 6 is provided with a hinge 7 and is hinged with the hinge seat 11 on the upper beam 10 of the bearing frame through the hinge 7, and the baffle plate is composed of Tiled and fixed on the frame composition 6 for carrying goods, the support seat 2 is fixed on the bottom of the frame composition 6, and the support seat 2 is set on the other side of the frame composition 6 relative to the hinge 7, and the number of the strut composition 8 is according to The length of the load-carrying and baffle composition along the direction of the crossbeam 10 is determined. I...

Embodiment 2

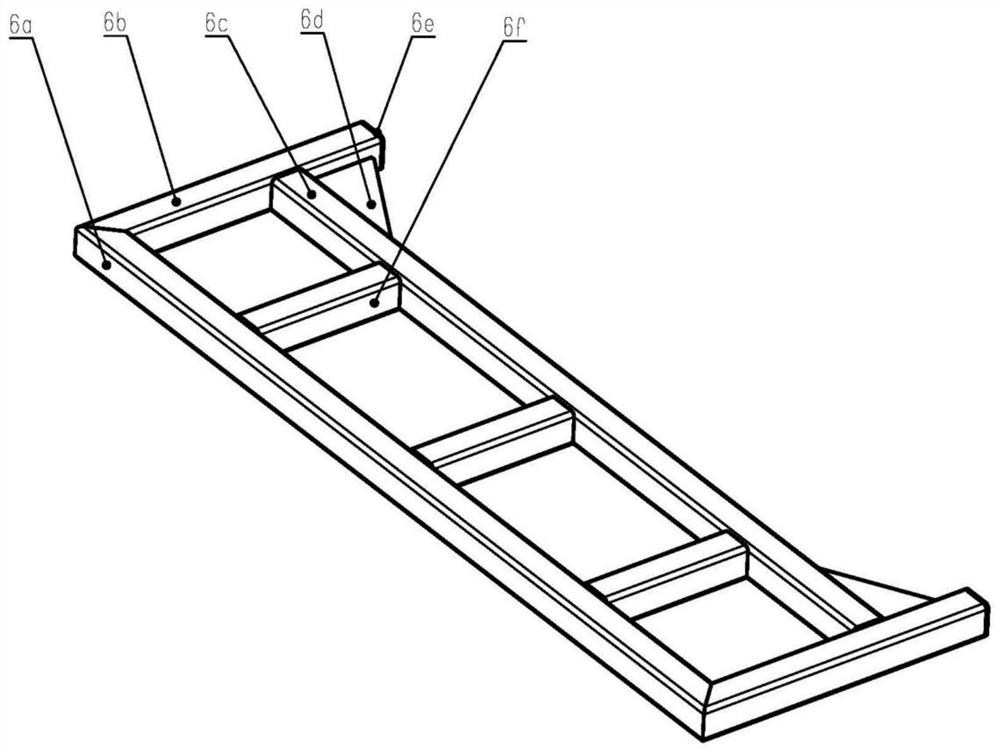

[0044] Embodiment 2 is basically the same as Embodiment 1, the difference is that: as a preferred solution of Embodiment 1, this embodiment provides a variable-angle baffle composition. Considering the stability of the overall structure, this embodiment provides The frame composition 6 includes a frame A6a, a frame B6b and a frame C6c, and the frame A6a, frame B6b and frame C6c are sequentially connected and fixed to form a word frame structure, so that the frame composition 6 has better structural stability, which is conducive to carrying goods. It is also beneficial to the fixed installation of the baffle plate; meanwhile, the frame B6b extends vertically along the two ends of the frame C6c; in order to reinforce the structure of the frame, the frame 6 provided by this embodiment also includes a pillar 6f, a sealing plate 6e and two ribs. 6d, the pillars 6f are evenly arranged and fixed inside the frame structure; the sealing plate 6e is fixed on the end of the frame B6b to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com