Reverse osmosis membrane filter element and water purifier

The technology of reverse osmosis membrane and filter element is applied in the field of reverse osmosis membrane filter element and water purifier, which can solve the problems of poor assembly and low water production, and achieve the effects of not easy to leak, uniform water production, and improving water production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

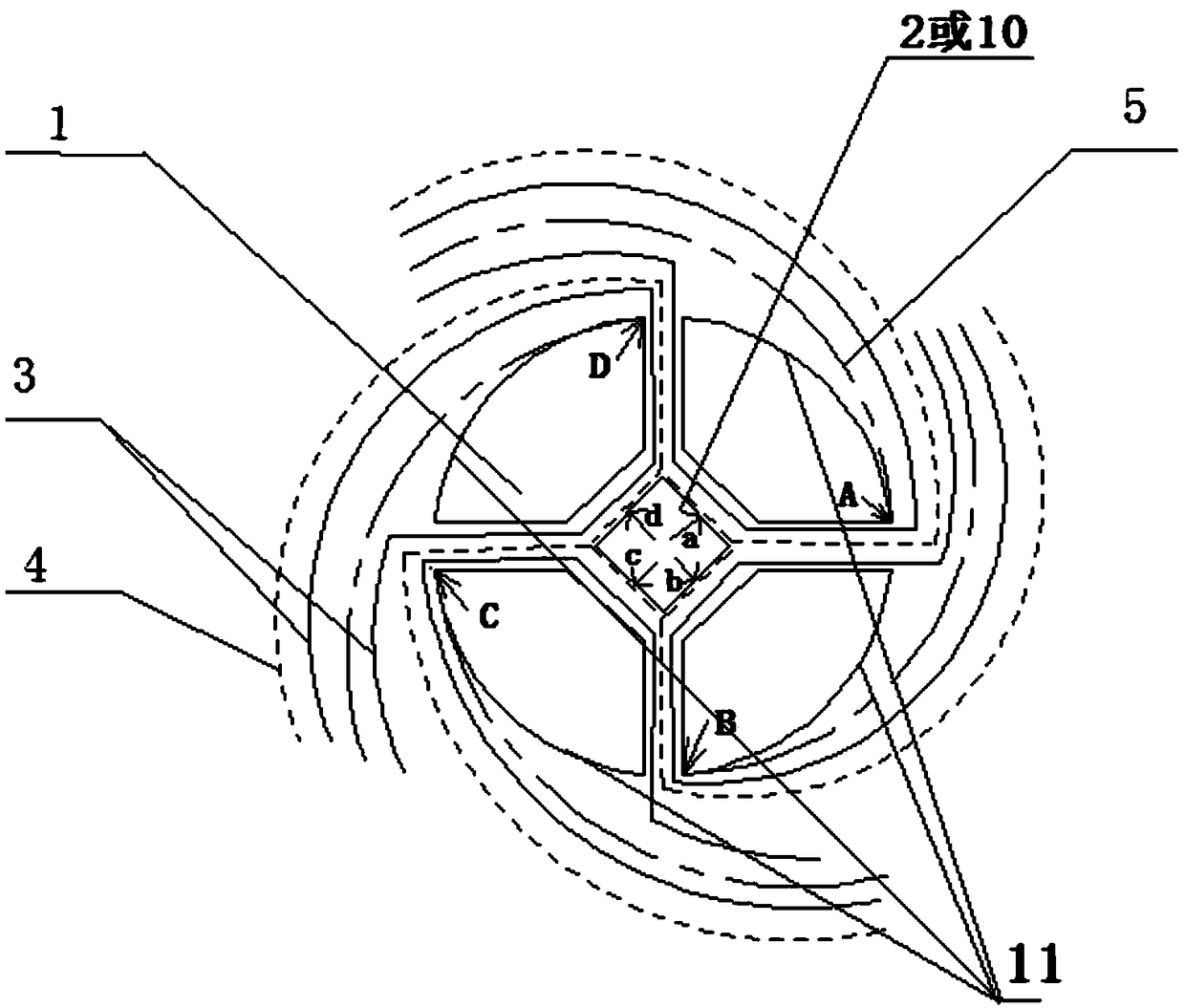

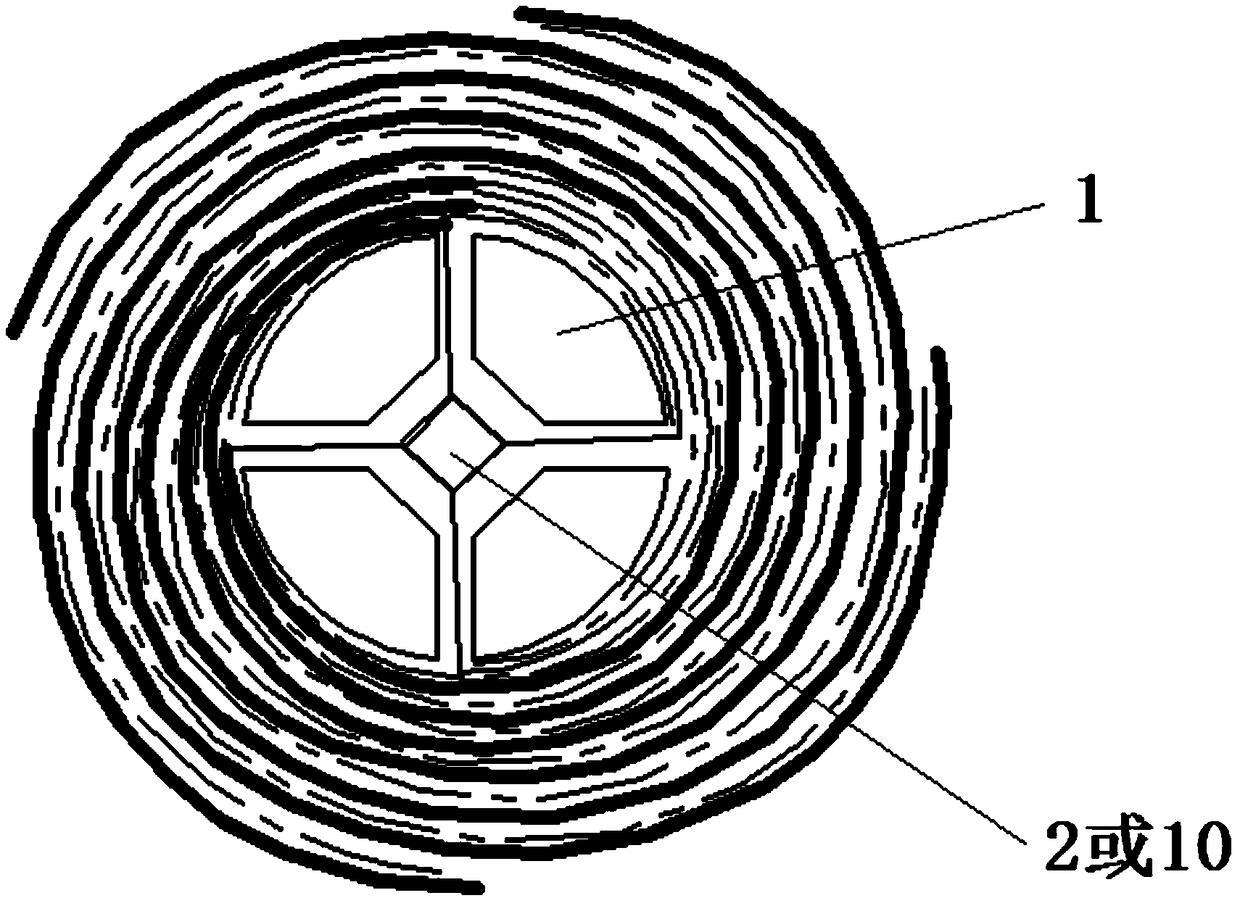

[0039] like Figure 1-4 Shown, a kind of reverse osmosis membrane filter element of the present invention comprises:

[0040] middleware;

[0041] The water inlet pipe 1 has several raw water outlet holes on its side wall, at least one end of the water inlet pipe 1 forms a raw water inlet, and several of the water inlet pipes 1 are arranged around the central part to form a central pipe group;

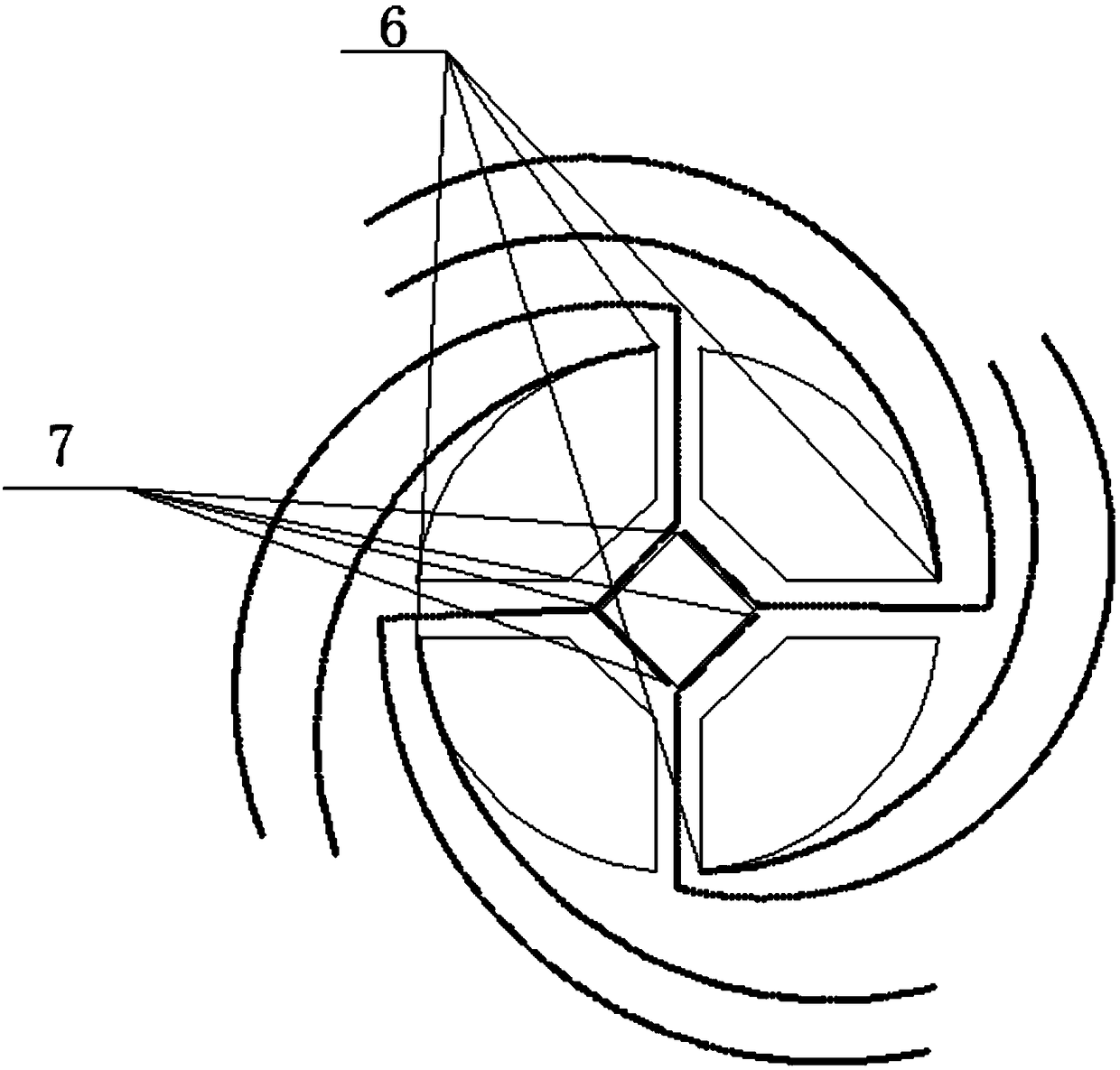

[0042] There are several reverse osmosis membrane sets, and the reverse osmosis membrane 3 in the reverse osmosis membrane set is passed between the central piece and the water inlet pipe 1, and rolled around the central tube set to form There are water inlet flow channels and water production flow channels; the reverse osmosis membrane group also includes a water inlet grid 5 arranged in each of the water inlet flow channels, and the starting side of the water inlet grid 5 is connected to the water inlet pipe 1, the installation outer wall 11 is the side wall of the water inlet pipe...

Embodiment 2

[0058] The difference between this embodiment 2 and embodiment 1 is that the central part is the central axis 10, the side of the produced water channel away from the pure water pipe 2 is sealed, and the side of the produced water channel along the At least one of the two sides in the axial direction of the central shaft 10 forms a pure water outlet.

[0059] A water purifier according to the present invention includes the above-mentioned reverse osmosis membrane filter element, which can improve water production efficiency and prevent leakage.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap