Acid salt corrosion resisting stainless steel and application thereof

A technology for corrosion of stainless steel and salt, applied in the field of stainless steel products, can solve problems such as poor mechanical properties and limited applicability, and achieve the effects of long service life, wide application fields, and broad-spectrum antibacterial and bacteriostatic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

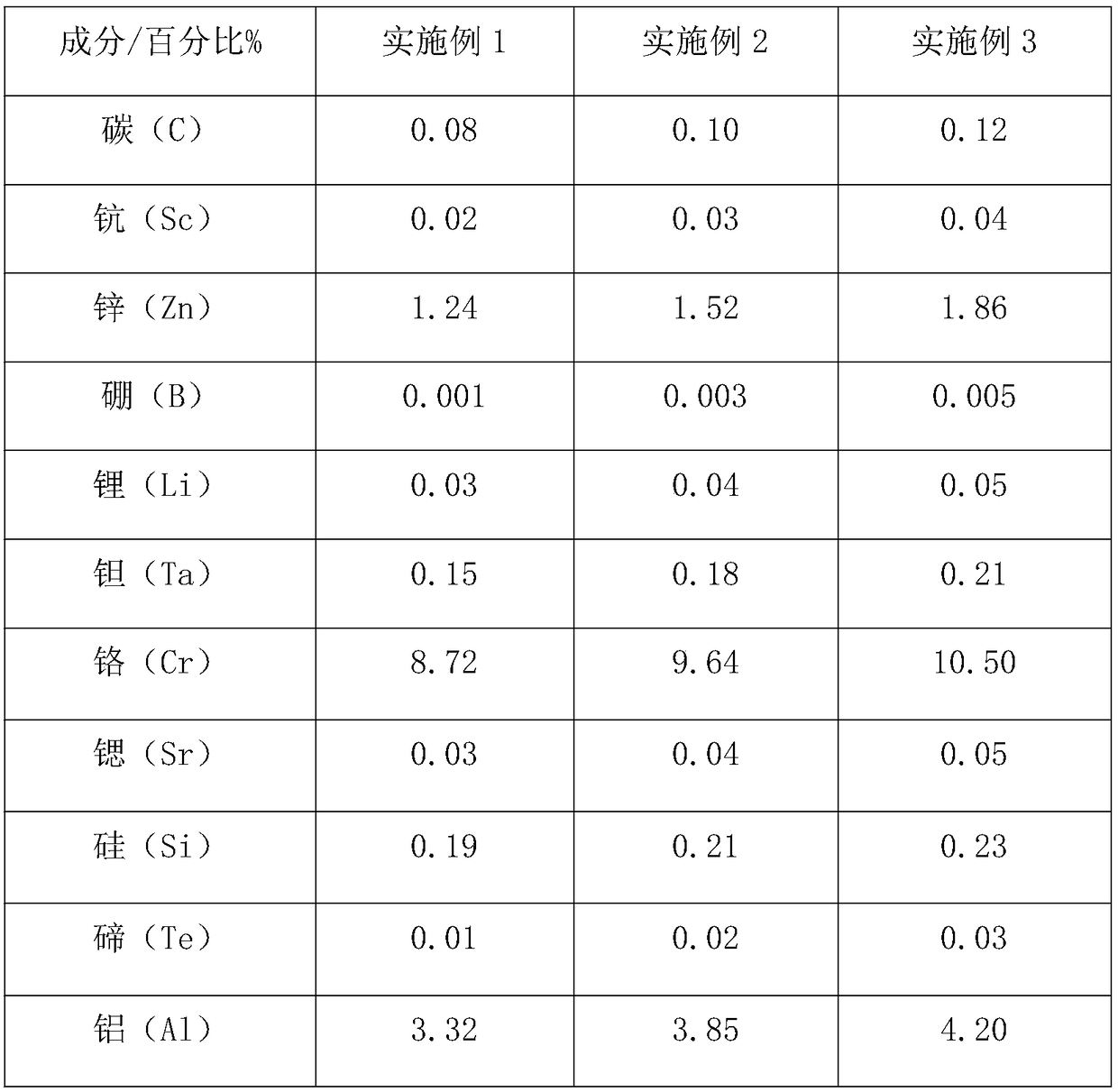

[0062] This embodiment relates to a preparation method of salt-resistant corrosion-resistant stainless steel, which is generally carried out according to the following steps:

[0063] Step 1: batching according to the mass percentage of the stainless steel composition in the above table 1;

[0064] Step 2: fully melting the ingredients containing C, B, Cr, Si and Fe to obtain melt I;

[0065] Fully melt the ingredients containing Zn, Al, Li, Sr, and Te to obtain melt II;

[0066] Add the ingredients containing Sc and Ta into the melt I, heat and melt fully to obtain the melt III;

[0067] Add melt II to melt III, stir and mix to obtain molten steel;

[0068] Step 3: Transfer the molten steel to the LF furnace again, add a refining agent equivalent to 1.60% of the molten steel mass, refine it at a temperature of 1620°C for 120 minutes, and then vacuum degas it in a VD vacuum degassing furnace for 30 minutes;

[0069]The above-mentioned refining agent is obtained by combining...

Embodiment 2

[0074] This embodiment relates to a preparation method of salt-resistant corrosion-resistant stainless steel, which is generally carried out according to the following steps:

[0075] Step 1: batching according to the mass percentage of the stainless steel composition in the above table 1;

[0076] Step 2: fully melting the ingredients containing C, B, Cr, Si and Fe to obtain melt I;

[0077] Fully melt the ingredients containing Zn, Al, Li, Sr, and Te to obtain melt II;

[0078] Add the ingredients containing Sc and Ta into the melt I, heat and melt fully to obtain the melt III;

[0079] Add melt II to melt III, stir and mix to obtain molten steel;

[0080] Step 3: Transfer the molten steel to the LF furnace again, add a refining agent equivalent to 1.70% of the molten steel mass, refine at a temperature of 1630°C for 110 minutes, and then vacuum degas in a VD vacuum degassing furnace for 32 minutes;

[0081] The above-mentioned refining agent is obtained by combining calc...

Embodiment 3

[0086] This embodiment relates to a preparation method of salt-resistant corrosion-resistant stainless steel, which is generally carried out according to the following steps:

[0087] Step 1: batching according to the mass percentage of the stainless steel composition in the above table 1;

[0088] Step 2: fully melting the ingredients containing C, B, Cr, Si and Fe to obtain melt I;

[0089] Fully melt the ingredients containing Zn, Al, Li, Sr, and Te to obtain melt II;

[0090] Add the ingredients containing Sc and Ta into the melt I, heat and melt fully to obtain the melt III;

[0091] Add melt II to melt III, stir and mix to obtain molten steel;

[0092] Step 3: Transfer the molten steel to the LF furnace again, add a refining agent equivalent to 1.80% of the molten steel mass, refine it at a temperature of 1640°C for 100 minutes, and then vacuum degas it in a VD vacuum degassing furnace for 34 minutes;

[0093] The above-mentioned refining agent is obtained by combinin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com