a socket-plug type structure of cast-in-situ UHPC material for prefabricating and assembling bridge piers

A prefabricated and socket-type technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of large difference in mechanical properties of materials, high risk, low efficiency, etc., and achieve horizontal shear resistance improvement and overall structural stability. , the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

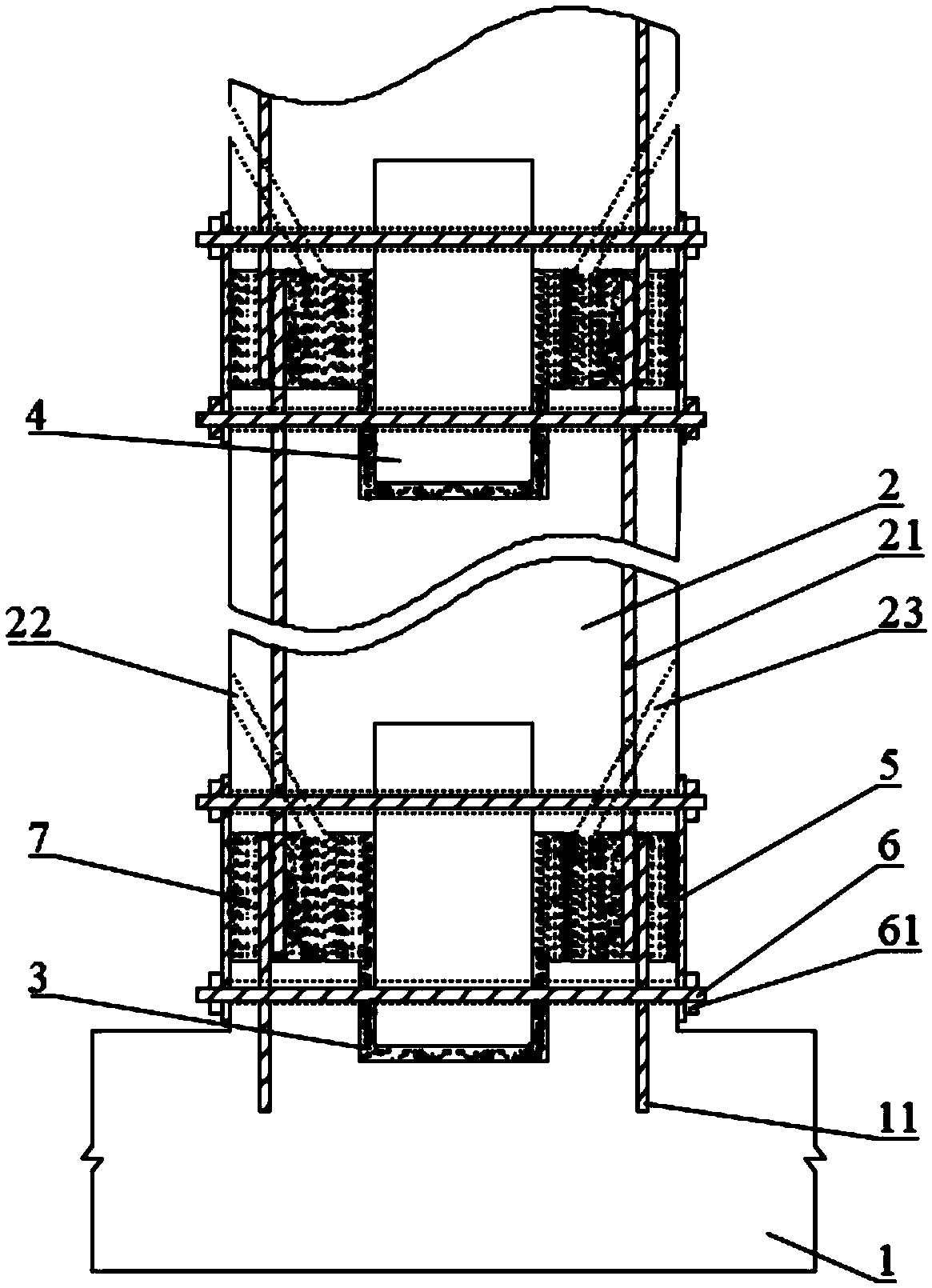

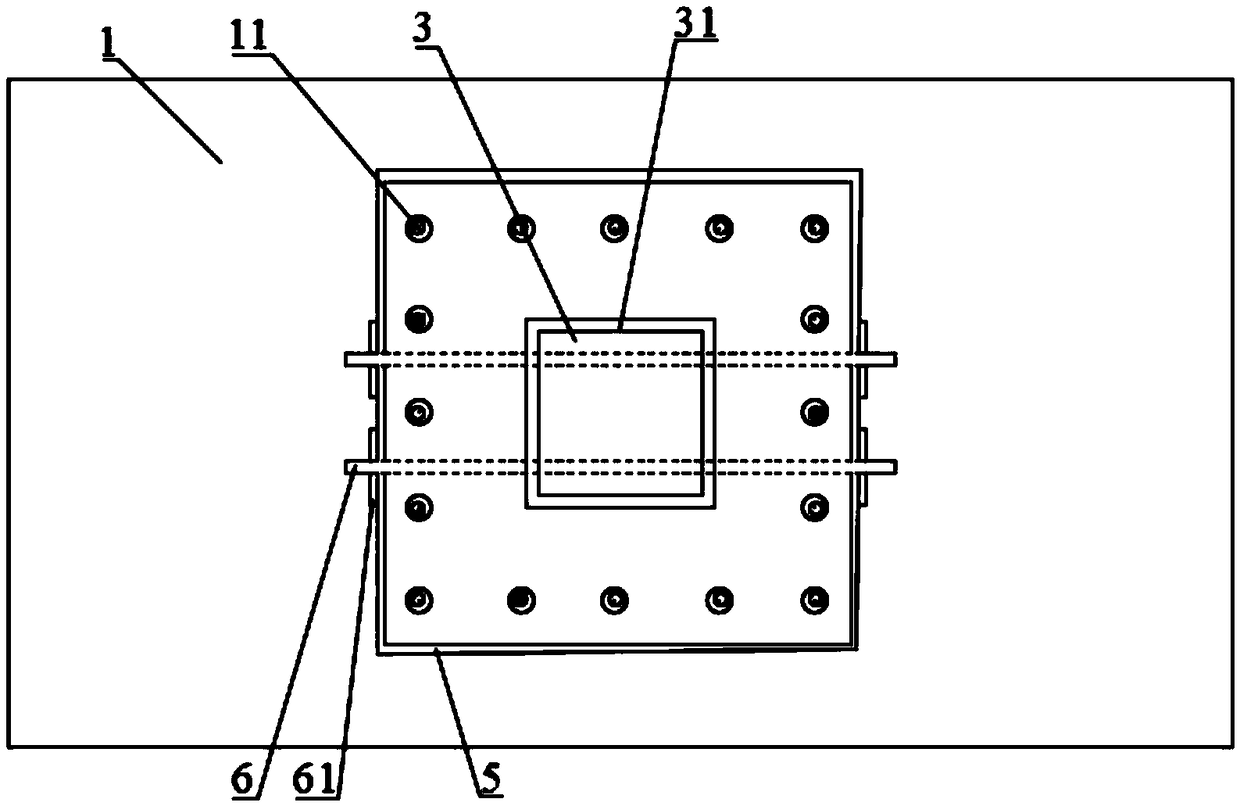

[0051] Please refer to figure 1 and figure 2 As shown, a prefabricated bridge pier with a socket-type structure made of cast-in-place UHPC material is used for joints, including a prefabricated bridge pier 1 and a prefabricated bridge pier 2, the prefabricated bridge pier 2 is installed on the prefabricated bridge pier 1, and multiple The prefabricated bridge piers 2 are stacked and installed; the top surface of the prefabricated platform 1 is provided with a raised part, and the top surface of the raised part and the top surface of the prefabricated bridge pier 2 are provided with a tenon groove 3, and the inside of the tenon groove 3 A steel pipe 31 is embedded, the bottom of the prefabricated bridge pier 2 is provided with a tenon 4, the size of the tenon 4 is adapted to the steel pipe 31, and the tenon 4 is embedded in the steel pipe 31; the tenon groove The depth of 3 is less than the protruding length of the tenon 4; the prefabricated pier 2 is pre-embedded with pier r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com