Water foam cleaning device

A cleaning device and foam technology, which is used in the cleaning of open water surfaces, water conservancy projects, construction, etc., can solve the problems of power consumption and time-consuming, foam floating, water resources waste, etc., to improve the speed of cleaning, reduce volume, improve The effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

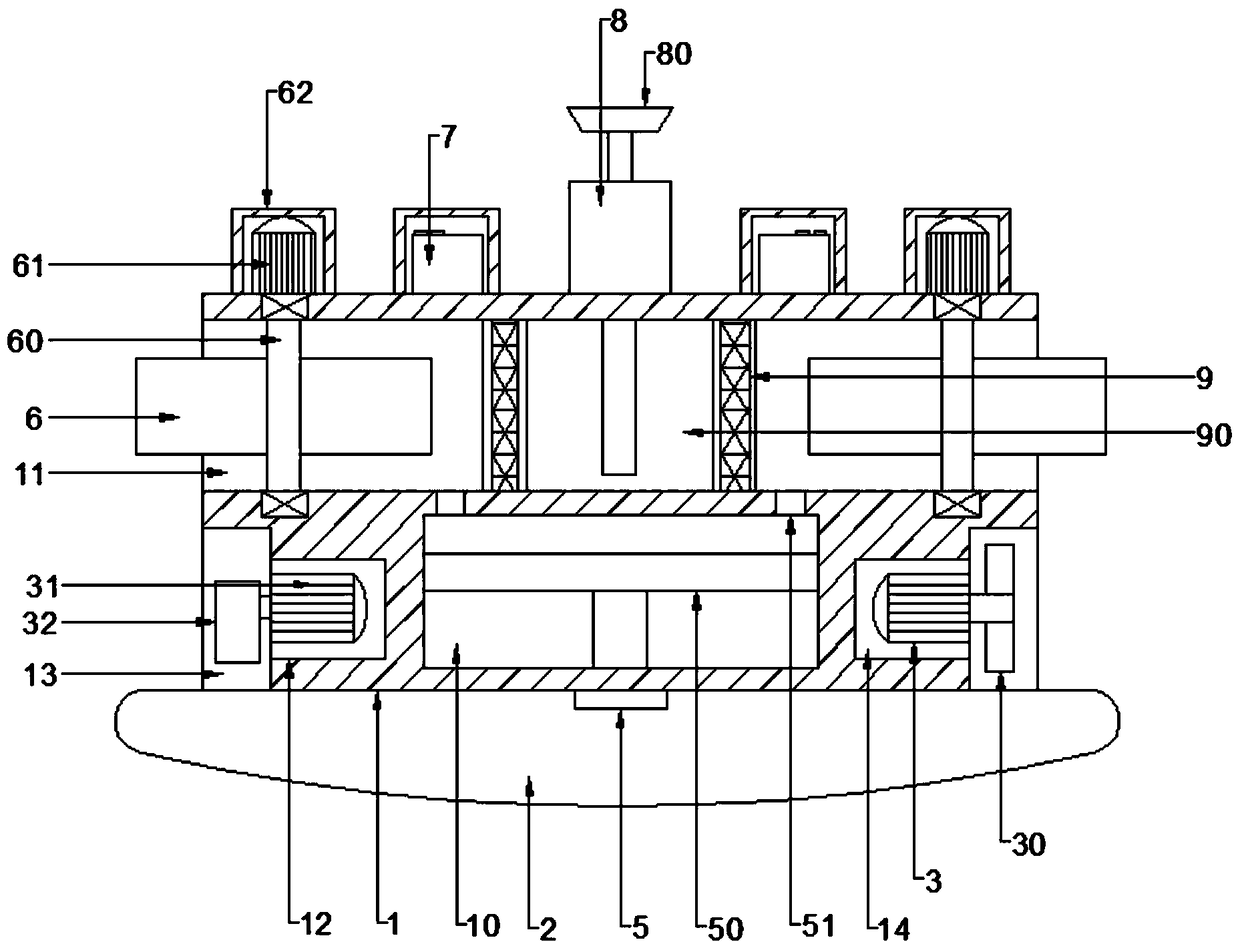

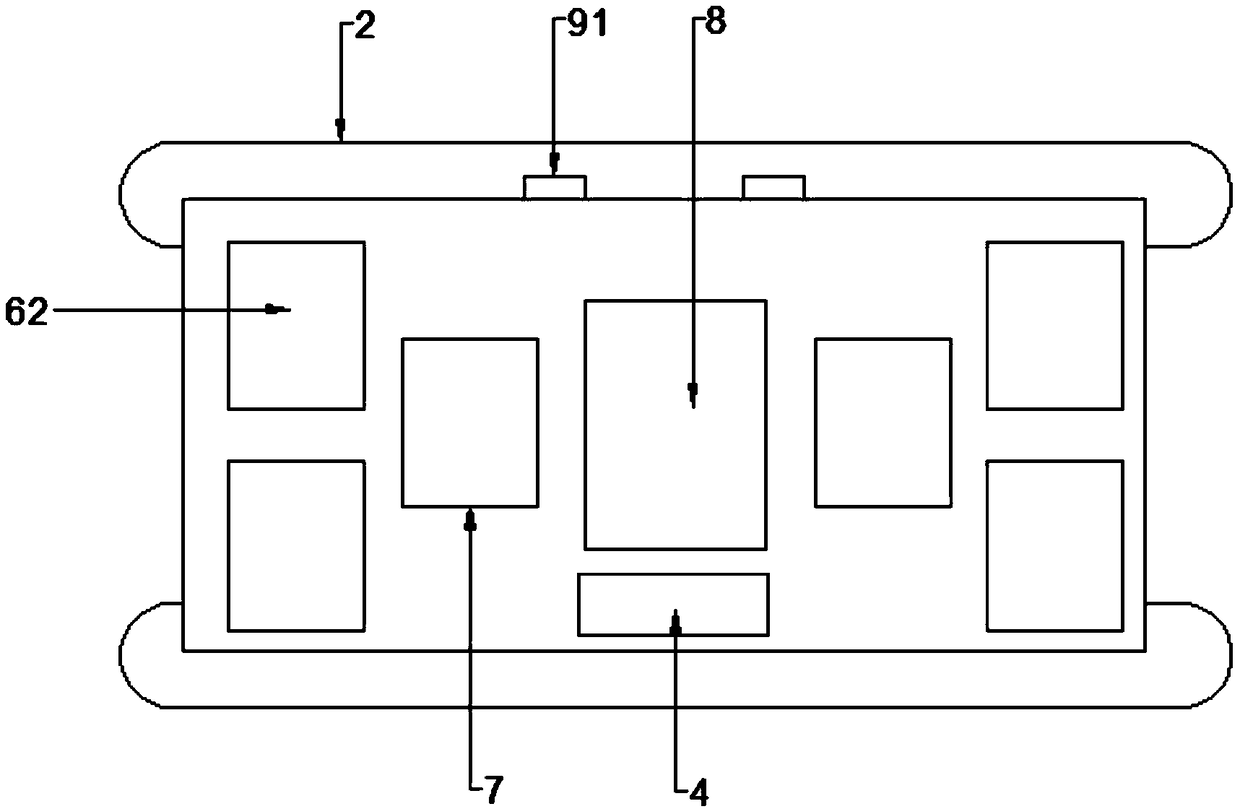

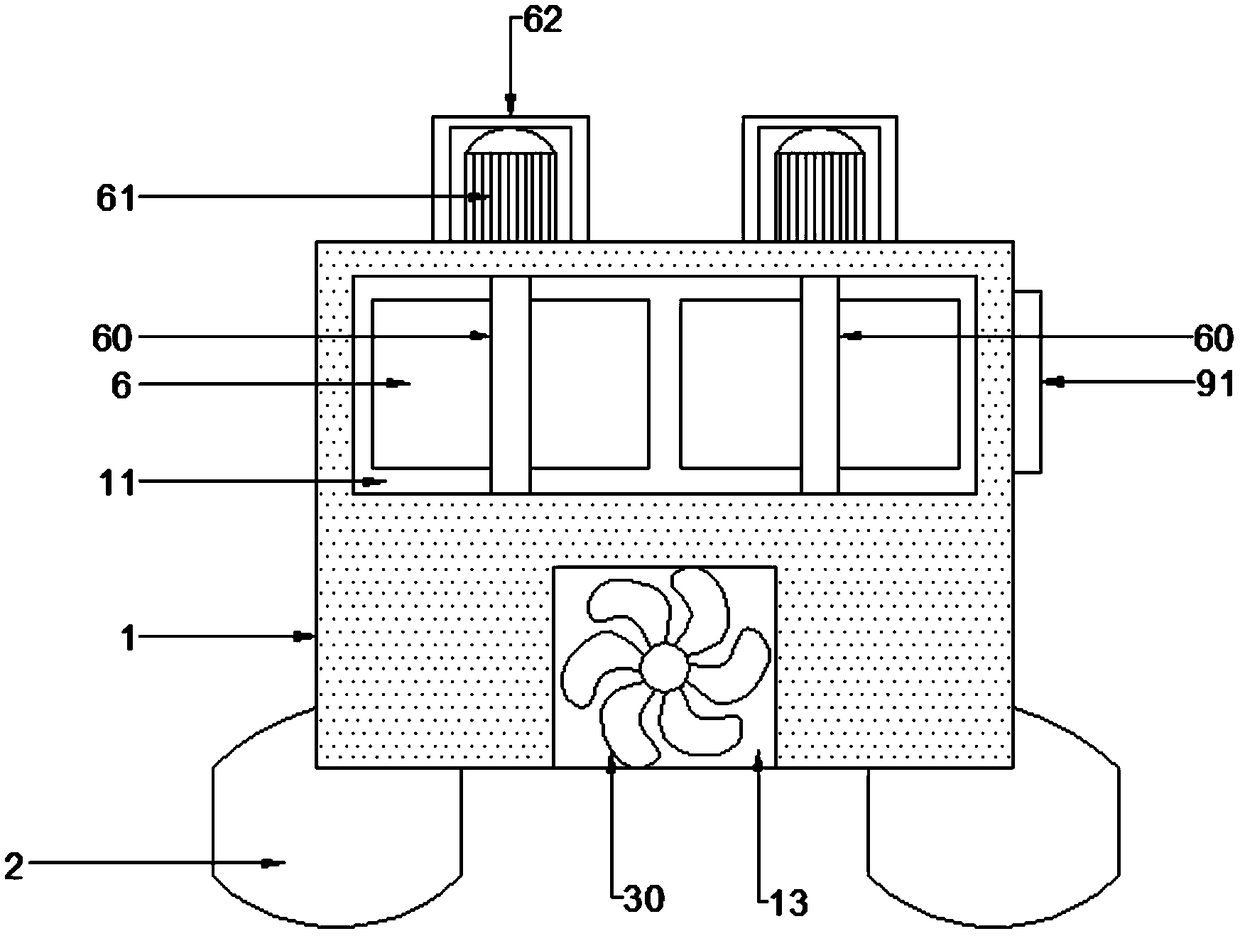

[0022] see Figure 1~5 , in an embodiment of the present invention, a water surface foam cleaning device includes a buoyancy tank 1, a pressure regulating chamber 10, a foam scraping chamber 11, a balance plate 2, a control box 4, a foam scraper 6, a water pump 8, and a filter chamber 90 , two balancing plates 2 are fixed on the front and rear sides of the bottom of the buoyant sinking tank 1, and the inner bottom of the buoyant sinking tank 1 is provided with a pressure regulating chamber 10, and the pressure regulating chamber 10 is clamped with a piston plate 50. A pressure regulating knob 5 is fixed at the center of the bottom surface of the piston plate 50. The pressure regulating knob 5 is threaded and penetrates the bottom surface of the buoyant sinking tank 1. The inner top of the floating sinking tank 1 is provided with a foam scraping chamber 11 connected to the left and right. There are two sets of opposite scraper boards 6 on the left and right sides of the interio...

Embodiment 2

[0026] see Figure 1~5 , in an embodiment of the present invention, a water surface foam cleaning device includes a buoyancy tank 1, a pressure regulating chamber 10, a foam scraping chamber 11, a balance plate 2, a control box 4, a foam scraper 6, a water pump 8, and a filter chamber 90 , two balancing plates 2 are fixed on the front and rear sides of the bottom of the buoyant sinking tank 1, and the inner bottom of the buoyant sinking tank 1 is provided with a pressure regulating chamber 10, and the pressure regulating chamber 10 is clamped with a piston plate 50. A pressure regulating knob 5 is fixed at the center of the bottom surface of the piston plate 50. The pressure regulating knob 5 is threaded and penetrates the bottom surface of the buoyant sinking tank 1. The inner top of the floating sinking tank 1 is provided with a foam scraping chamber 11 connected to the left and right. There are two sets of opposite scraper boards 6 on the left and right sides of the interio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap