Method for installing lightweight wall boards

A technology of lightweight wall panels and installation methods, applied in the direction of adhesive types, polyurea/polyurethane adhesives, adhesive additives, etc. Firmness and other issues, to achieve the effect of reducing the gap between the walls, good seismic effect, and avoiding excessive stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples can help those skilled in the art to understand the present invention more comprehensively, but the present invention cannot be limited in any way.

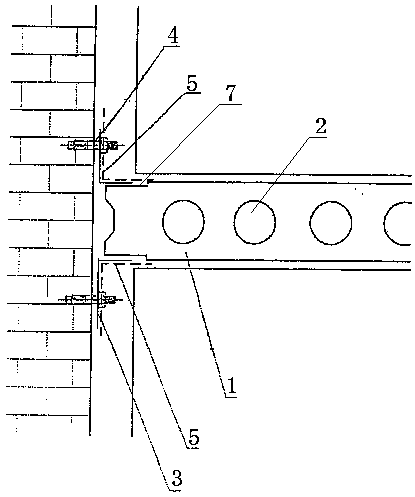

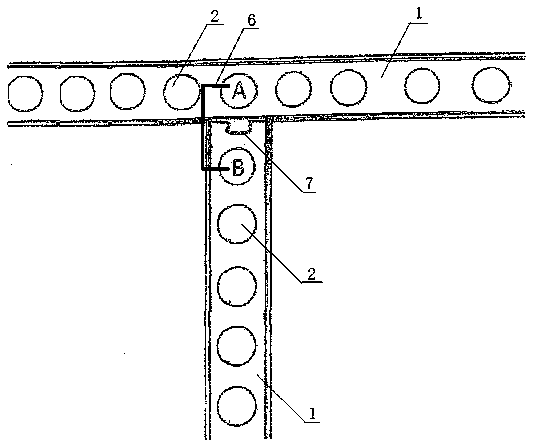

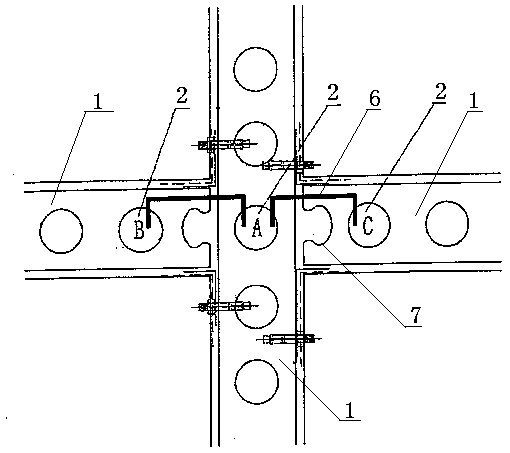

[0026] Such as Figure 1-3 Shown: an installation method of a lightweight wallboard, the shape of the lightweight wallboard 1 is a rectangle, the front and rear sides of the lightweight wallboard 1 are respectively provided with grooves 7, and the lightweight wallboard 1 The left and right sides of the panel 1 are provided with a number of through holes 2 parallel to the groove 7, and the installation method of the lightweight wall panel 1 is as follows:

[0027] (1) The connection method between the lightweight wallboard 1 and the wall: the front side of the lightweight wallboard 1 is fixedly connected to the wall through the support piece 3 and the bolt 4. The upper and lower ends of the front side of the wall panel 1, the support 3 is fixedly connected to the wall by bolts 4, the inner corner of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com