Sub-frame and pre-buried structure and method thereof

A sub-frame and pre-embedded technology, applied to the base frame, building components, frame fixing, etc., can solve problems such as increasing the occurrence rate of quality problems, leakage, and increased operating procedures, so as to improve construction efficiency, speed up construction progress, The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

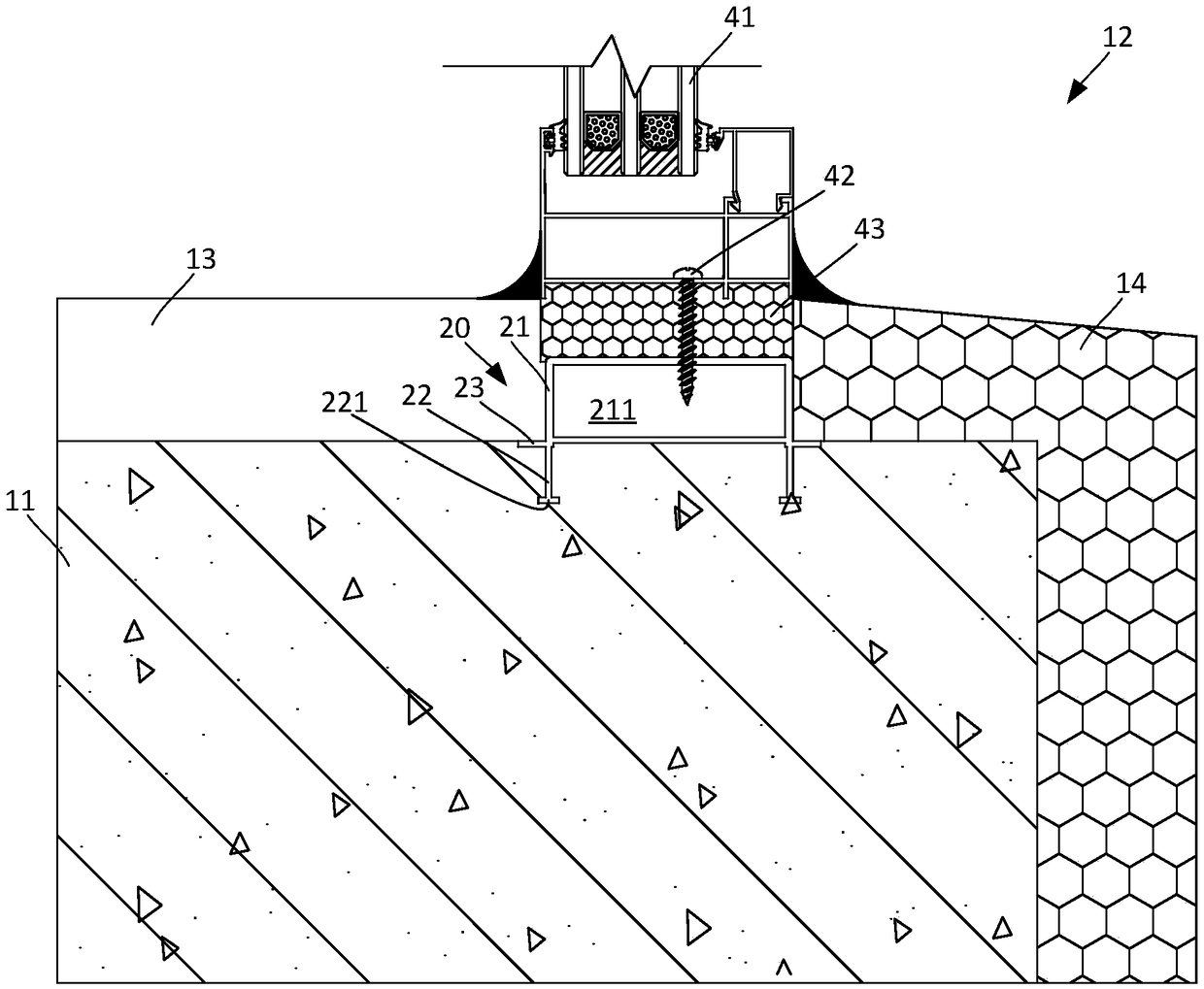

[0068] As another preferred embodiment of the present invention, it further includes:

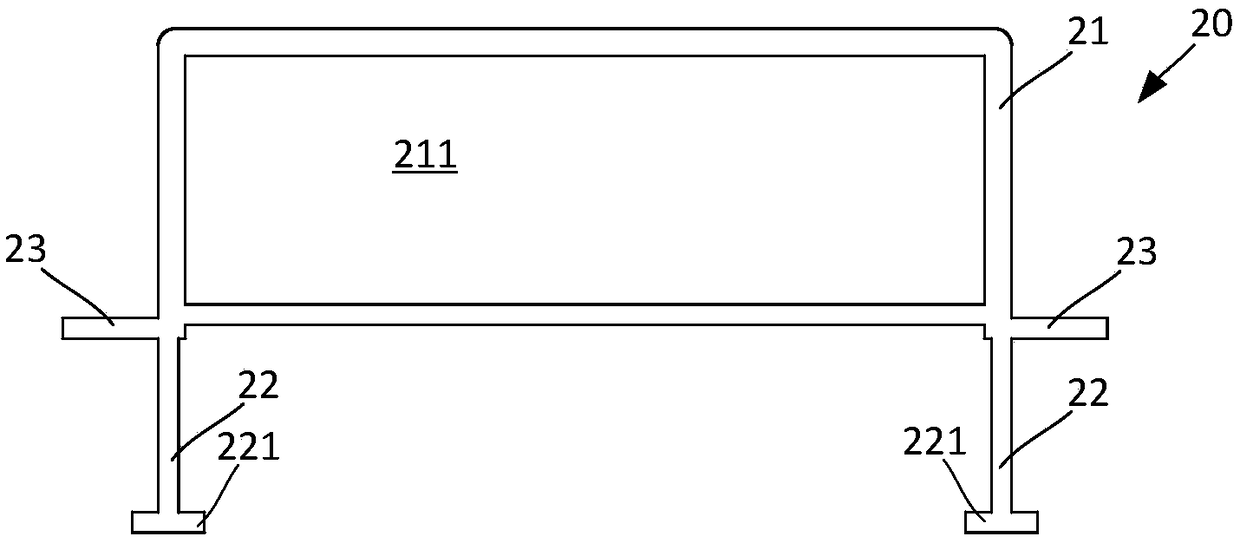

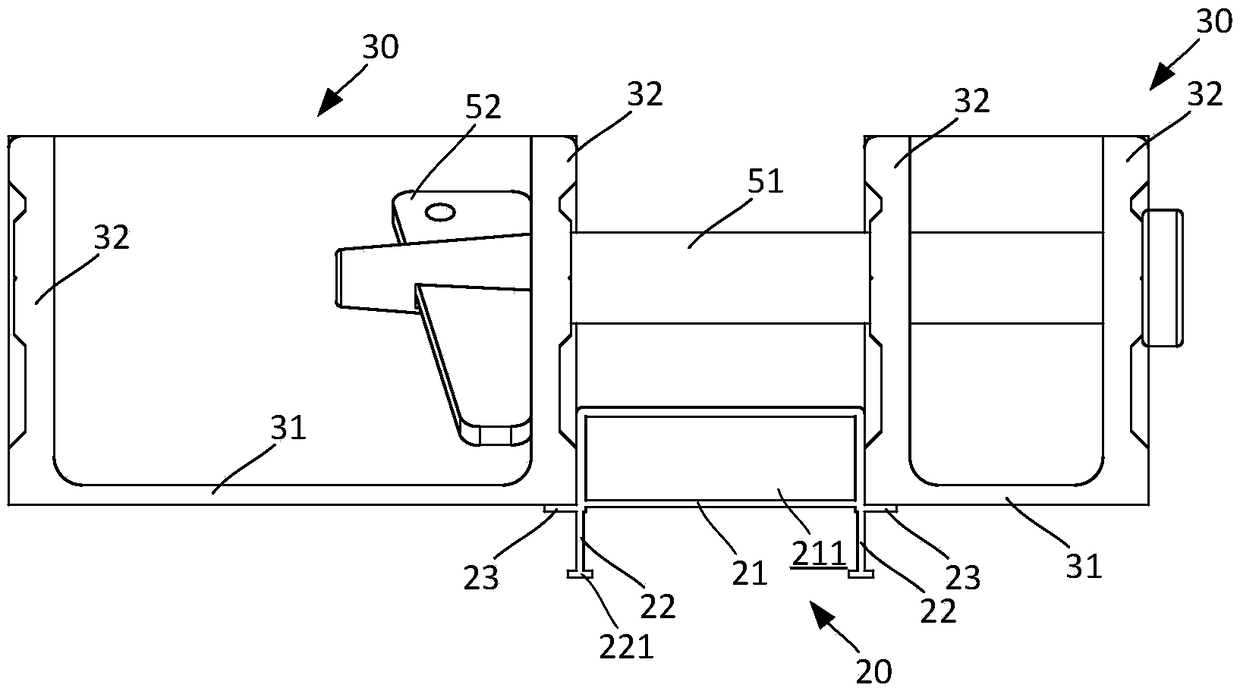

[0069] A bottom plate 221 is vertically connected to the bottom end of the anchor plate 22. When the subframe 20 is set, the bottom plate 221 is attached to the corresponding steel bars in the wall formwork.

[0070] Utilizing the provided bottom plate 221 can improve the stability of the installation of the sub-frame 20. When the sub-frame 20 is installed, the bottom plate 221 abuts on the corresponding wall reinforcement to provide a certain supporting force for the sub-frame 20. Preferably, the bottom plate 221 is fixedly connected with the corresponding wall reinforcement.

[0071] The pre-embedding method of the present invention further includes: after the wall reaches the design strength, the wall template and the window template are removed, and the sub-frame 20 is left on the wall 11. Then install the window 41 on the square frame 21 of the sub-frame 20. The main frame of the window 41 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com