Rope salvaging type hydraulic compulsory coring driller

A technology for coring drills and coring bits, which is used in the extraction of undisturbed core devices, earth-moving drilling, wellbore/well components, etc., can solve high requirements for hydraulic dynamic sealing, in-hole accidents, and excessive extrusion of alarm gaskets and other problems, to achieve the effect of increasing the core extraction rate, improving the effect of breaking the core, and reducing the suction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

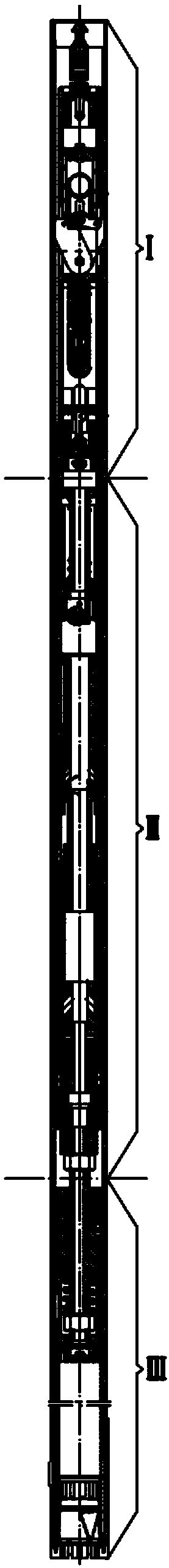

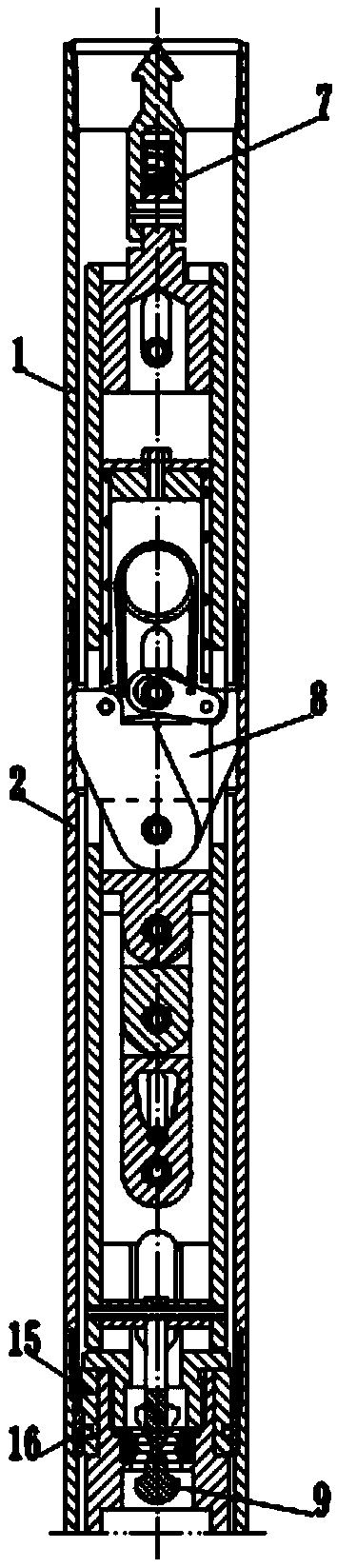

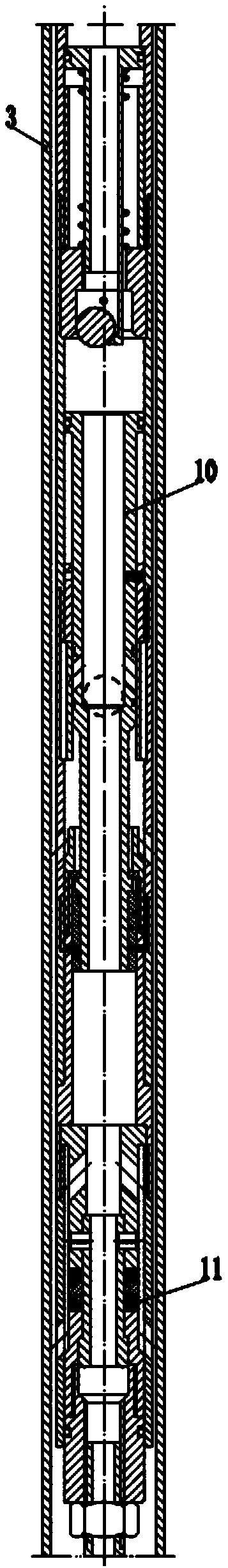

[0032] See Figure 1, figure 2 , image 3 , Figure 4 , the present invention is a rope salvage type hydraulic forced core drilling tool, which includes an outer tube assembly and an inner tube assembly; 3. Hole reamer 4, centering ring 5 and core bit 6, the cartridge stopper 1, cartridge chamber 2, outer tube 3, hole reamer 4, centering ring 5 and core bit 6 from top to bottom Assembled in sequence to form a cavity through up and down; the inner tube assembly is placed in the cavity of the outer tube assembly, and the axial positioning of the inner tube assembly is realized through the cooperation of the sealed suspension ring 15 and the seat ring 16, and the inner tube assembly From top to bottom, set up the spear head assembly 7, the bullet card positioning mechanism 8, the in-position reporting mechanism 9, the forced coring differential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com