Water-based drilling fluid for drilling, and preparation method and purpose thereof

A drilling fluid and water-based technology, applied in the field of drilling water-based drilling fluid and its preparation, can solve the problems of unstable oil-based drilling fluid cost, failure to obtain core hole wall, etc. The effect of inhibiting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention are described below in conjunction with the following examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

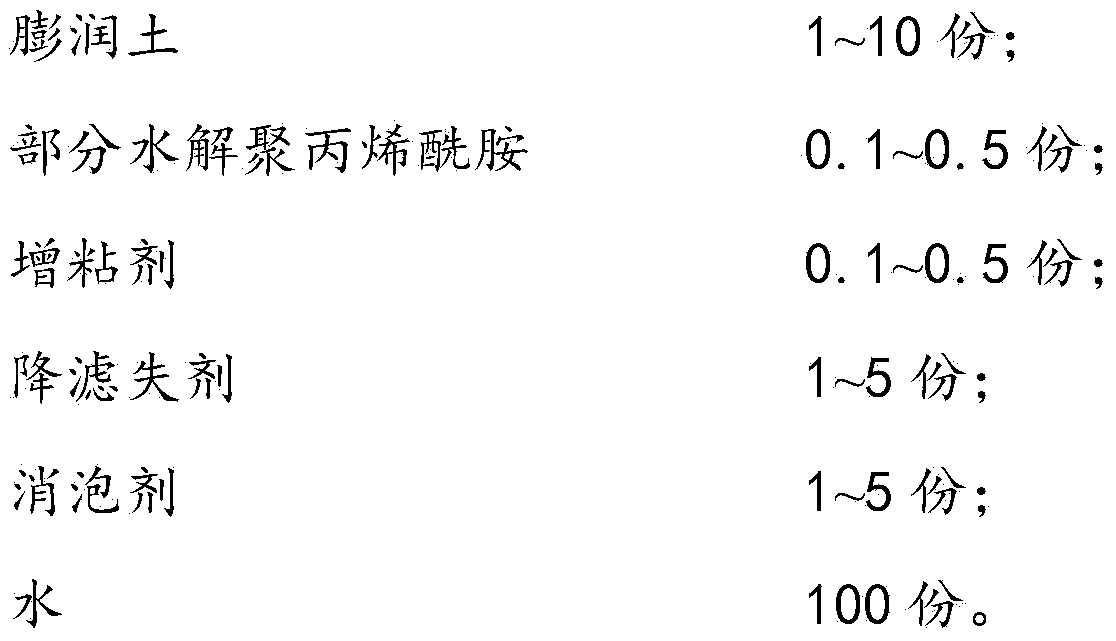

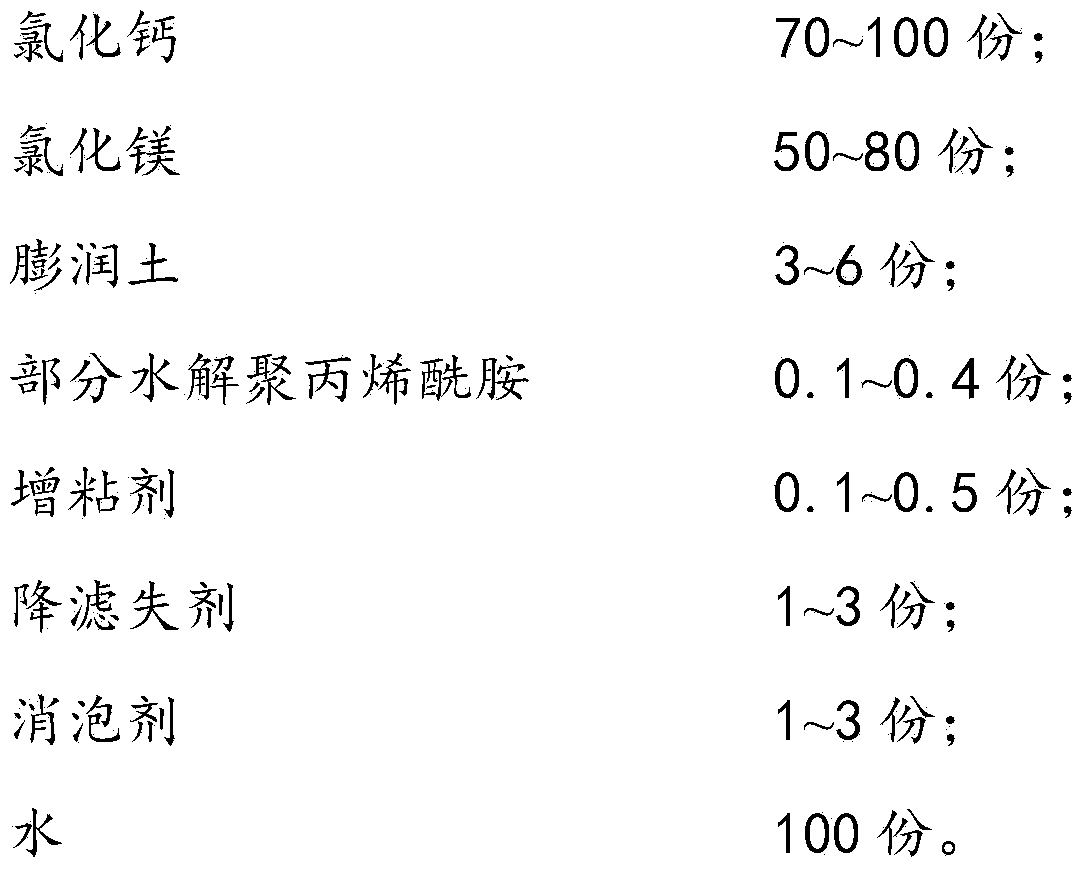

[0020] The preparation method of water-based drilling fluid for drilling in Example 1 to Example 6 of the present invention is as follows: take bentonite and partially hydrolyzed polyacrylamide in parts by weight, dissolve them in equal parts of water respectively, stir evenly, and then add the above two solutions after mixing Calcium chloride, magnesium chloride, viscosifier, fluid loss reducer and defoamer can be prepared by fully stirring evenly, which is suitable for water-based drilling fluid for drilling of potassium rock ore bodies containing episprite.

[0021] The weight ratio of each raw material described in embodiment 1 to embodiment 6 is shown in table 1.

[0022] See Table 2 for the measurement data of the effect of adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com