A Prediction Method of Caprock Sealing Performance in Ordos Basin

A performance prediction and cap rock technology, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., can solve the problems of expensive, time-consuming, inaccurate, etc., and achieve the goal of simple prediction method, avoiding time and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

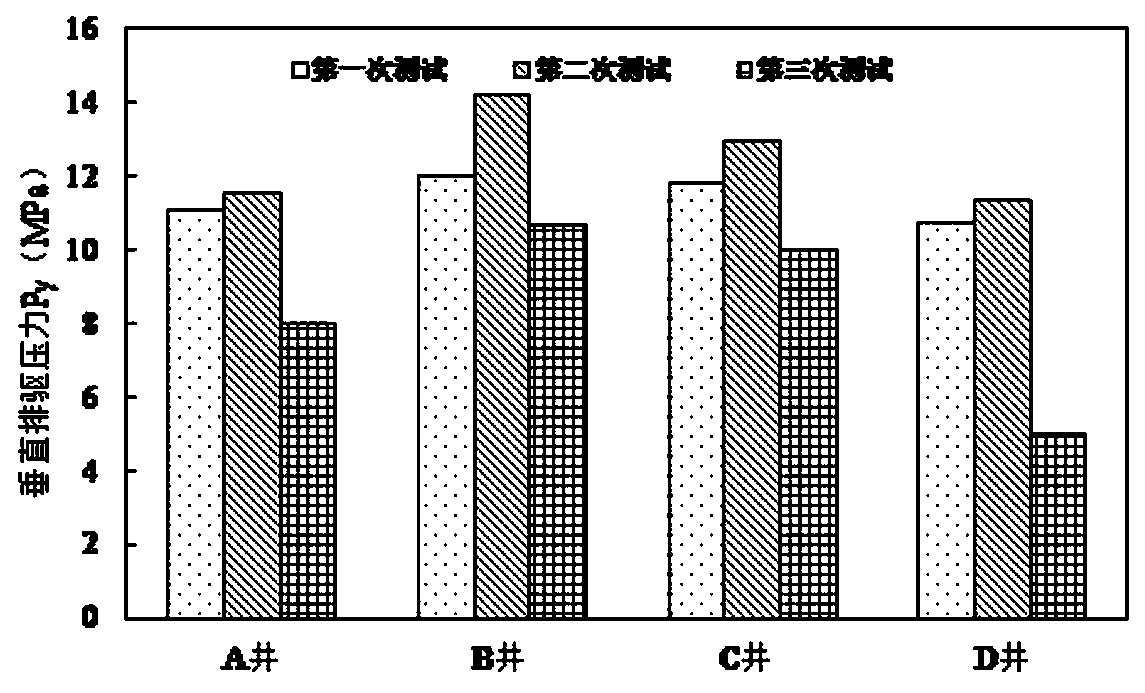

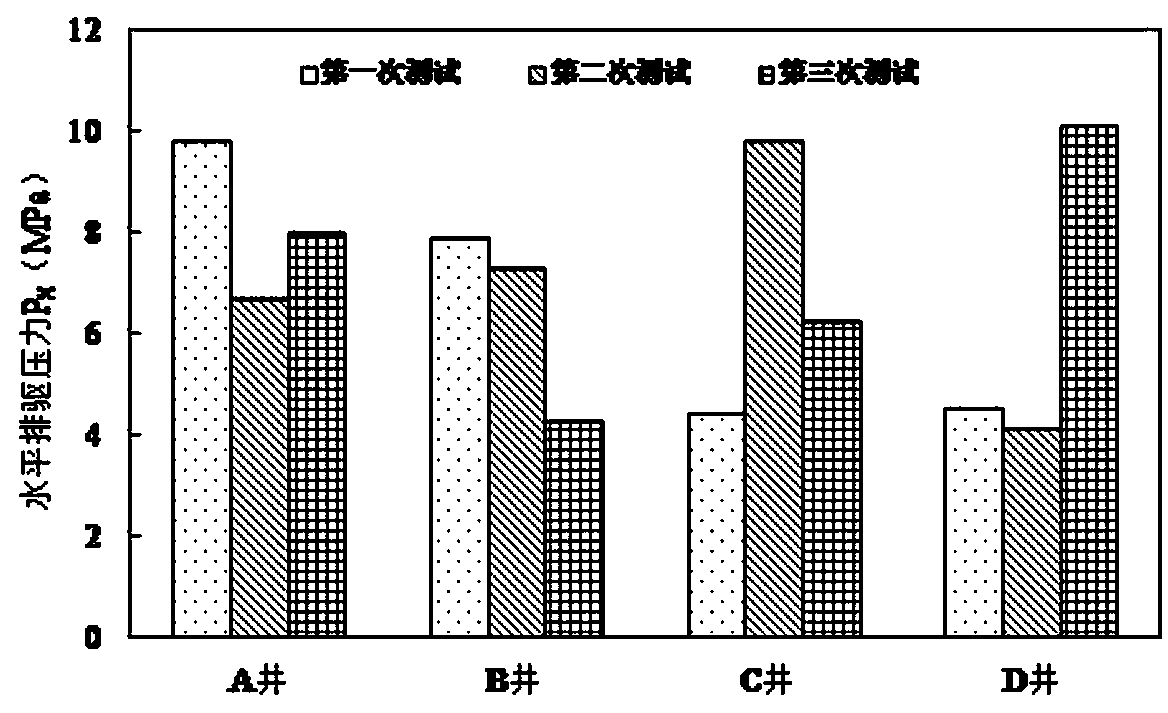

[0024] Step 1: Select four wells A, B, C, and D in a certain block as evaluation objects, and these 4 wells are the same 4 wells as in the background technology;

[0025] Take well A as an example, measure its logging curve, and get the initial depth value x of the long 4+5 caprock 1 It is 1183.5m, and the thickness h is 85.3m.

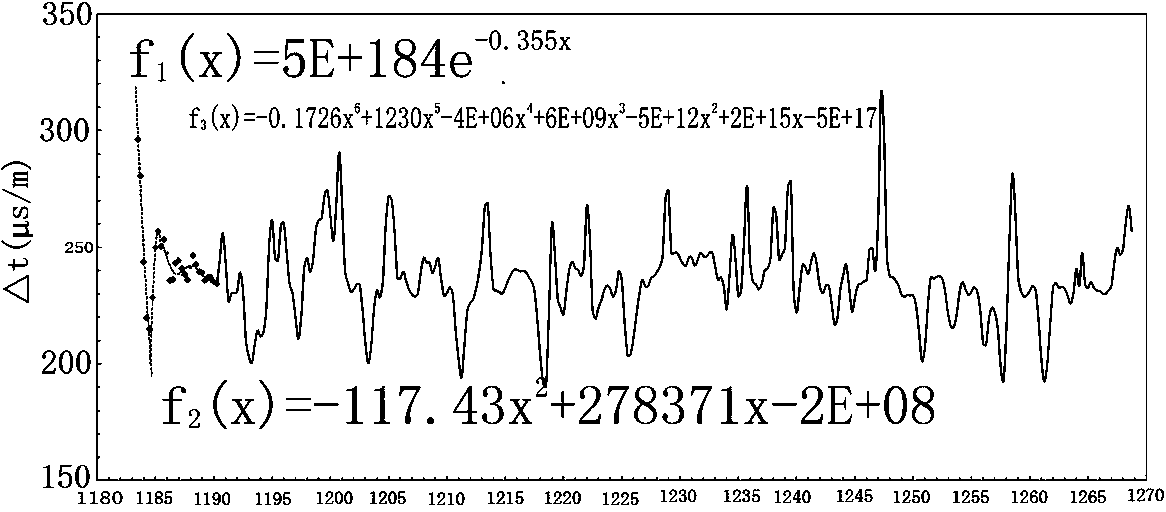

[0026] Step 2: Perform function fitting on the acoustic wave time difference curve in segments to obtain the fitting function f 1 (x), f 2 (x), f 3 (x)... f n (x) and the depth difference Δh corresponding to each segment function i , where f 1 (x), f 2 (x), f 3 (x)... f n (x) The corresponding depth difference is Δh 1 、Δh 2 、Δh 3 …Δh n .

[0027] For example, f in the fitting function 1 (x), f 2 (x), f 3 (x) are respectively:

[0028] f 1 (x)=5×10 184 e -0.355x ;

[0029] f 2 (x)=-117.43x 2 +278371x-2×10 8 ;

[0030] f 3 (x)=-0.1726x 6 +1230x 5 -4×10 6 x 4 +6×10 9 x 3 -5×10 12 x 2 +2×10 15 x-5×10 17 ;

[0031] Calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com