Universal decompression device and decompression method for marine hydraulic system

A hydraulic system and decompression device technology, applied in the direction of fluid pressure actuators, servo motors, servo meter circuits, etc., can solve the problems of high construction costs and large deck area occupied by hydraulic systems, and achieve reliability and safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

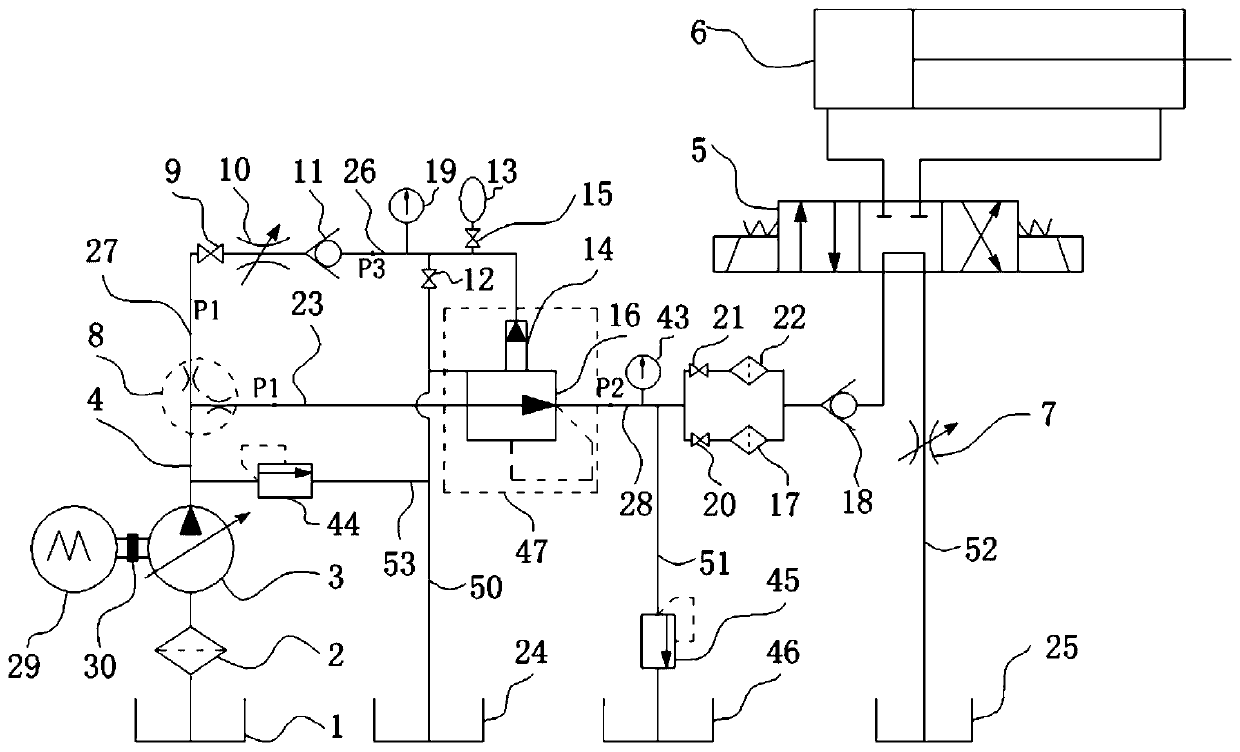

[0056] As shown in the figure, a general-purpose pressure reducing device for marine hydraulic systems includes an oil tank 1, a one-way variable hydraulic pump 3, an electric motor 29 and a fixed-value pressure reducing valve 47, the oil tank 1 and a one-way variable hydraulic pump 3 The first oil filter 2 is installed on the oil path of the oil circuit. The electric motor 29 drives the one-way variable hydraulic pump 3 to move through the coupling 30; the one-way variable hydraulic pump 3 is connected with an output pipeline 4, the output pipeline 4 The pressure reducing valve pilot line 27 and the pressure reducing valve inlet line 23 are respectively connected through the diverter valve 8;

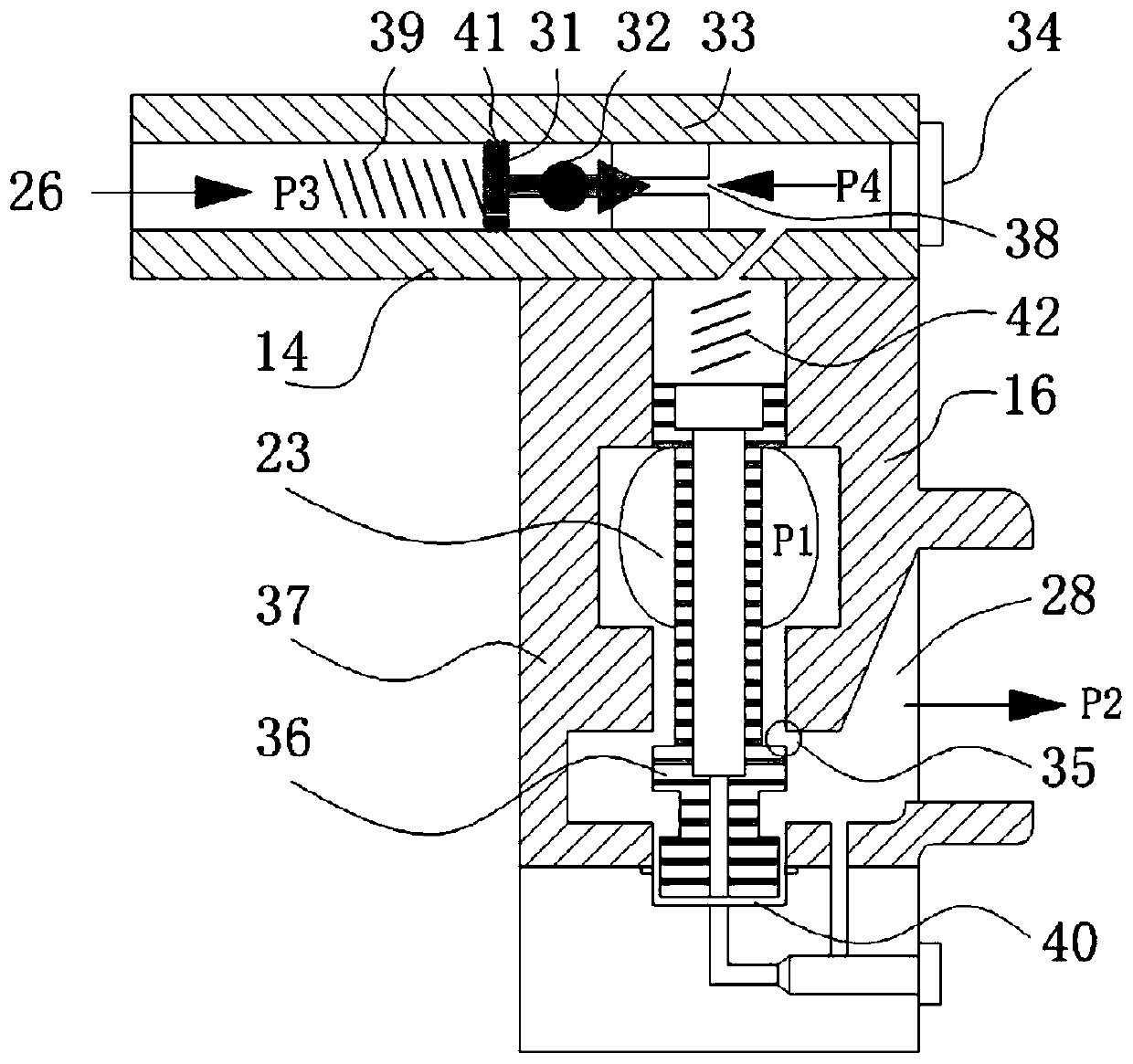

[0057] The fixed-value pressure reducing valve 47 includes the pilot valve 14 of the pilot pressure reducing valve and the main valve 16 of the pilot pressure reducing valve. The inlet pipe 23 of the pressure reducing valve is directly connected with the main valve 16 of the pilot pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com