A short end threaded fastener

A threaded fastener and thread technology, applied in the field of aerospace fastener manufacturing, can solve problems such as high risk, high cost, and complicated processing process, and achieve the effects of avoiding damage to polished rods, reducing overall weight, and simple processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

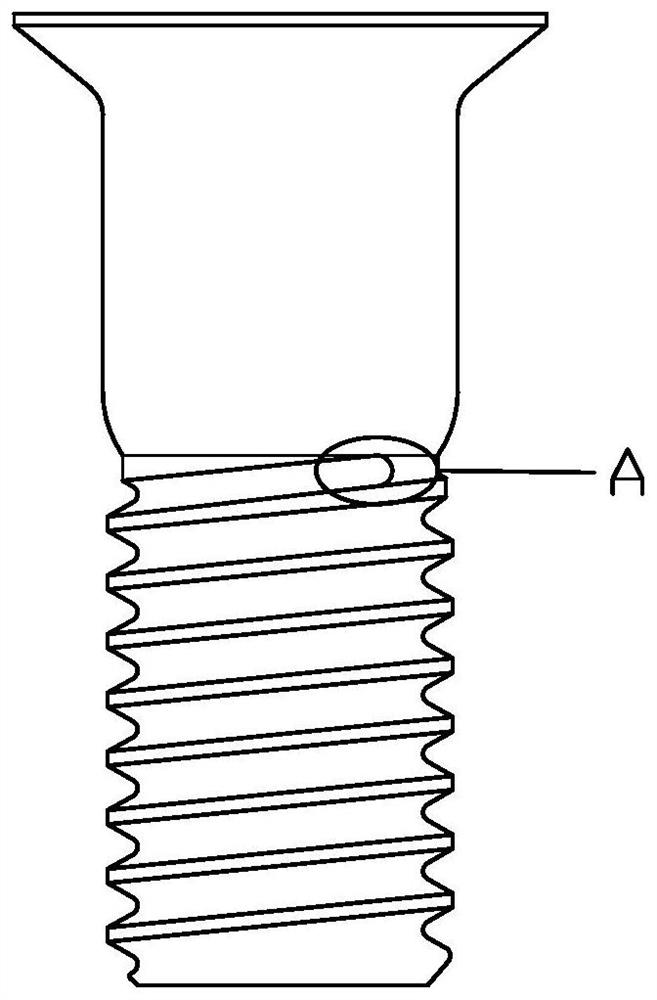

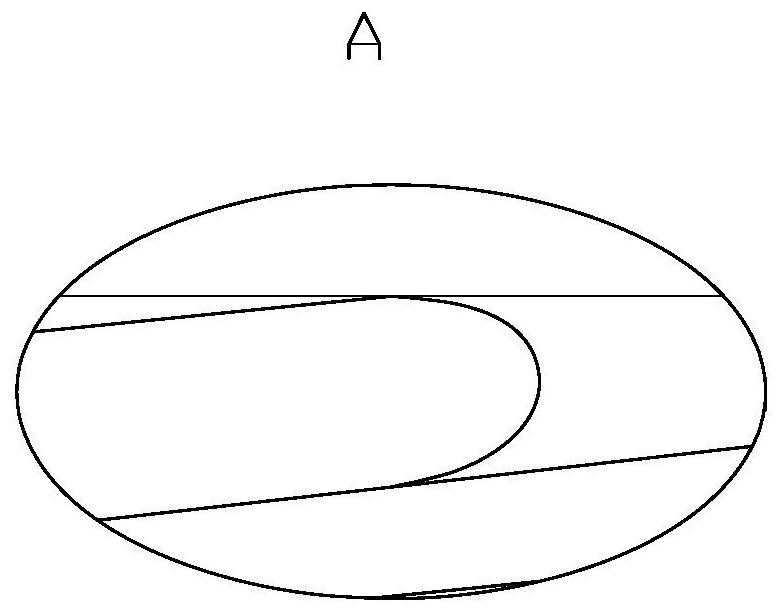

[0023] figure 1 It is a schematic diagram of a short end threaded fastener of the present invention. combine 1 and figure 2 As shown, the fastener includes a threaded portion and a polished rod portion, and the threaded portion further includes a thread working area and a thread ending area, wherein the length of the thread working area is much larger than the thread ending area, and the thread ending area transitions to the polished stem portion, along the thread The ending transition end face of the trend is an arc ending end face, the pitch of the thread ending area and the thread working area is P, and the radius of the arc ending end face is R, where R≥P / 2.

Embodiment 2

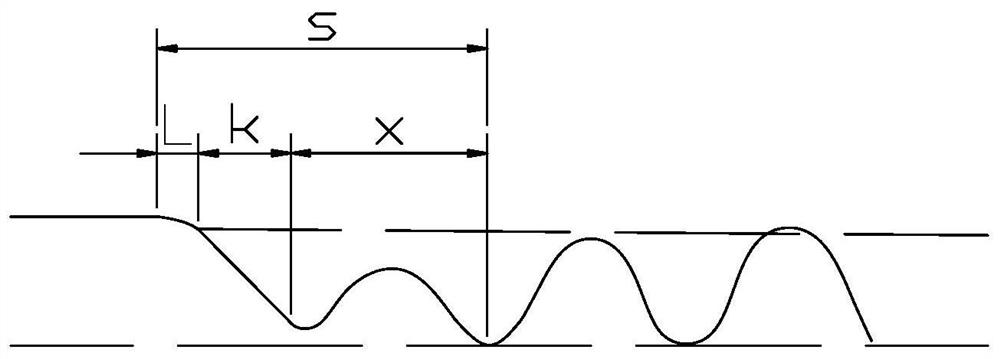

[0025] combine 1 and image 3 As shown, a short-finished threaded fastener includes a threaded portion and a polished stem portion, and the threaded portion further includes a threaded working area and a threaded ending area, wherein the length of the threaded working area is much greater than the thread ending area, from the thread The ending area transitions to the polished rod part. The ending transition end face along the thread direction is an arc ending end face. 2. Along the axial direction of the threaded fastener, the transition shaft section from the polished rod part to the thread ending area is a tapered arc conical shaft section, and the axial length of the tapered arc conical shaft section is L. Suppose the length of the thread ending area is S, and its calculation formula is: S=L+K+X, where K is a fixed value related to the thread profile, and X is the incomplete thread of the thread ending area in the axial direction. length.

[0026] Further, the length X of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com