A torsional quasi-zero stiffness vibration isolator with adjustable negative stiffness and its control method

A quasi-zero stiffness, vibration isolator technology, applied in the direction of rotation vibration suppression, spring/shock absorber functional characteristics, spring/shock absorber design characteristics, etc., can solve problems such as difficult miniaturization, poor controllability, and complex structure , to achieve low dynamic stiffness, compact structure, and broaden the effect of vibration isolation frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

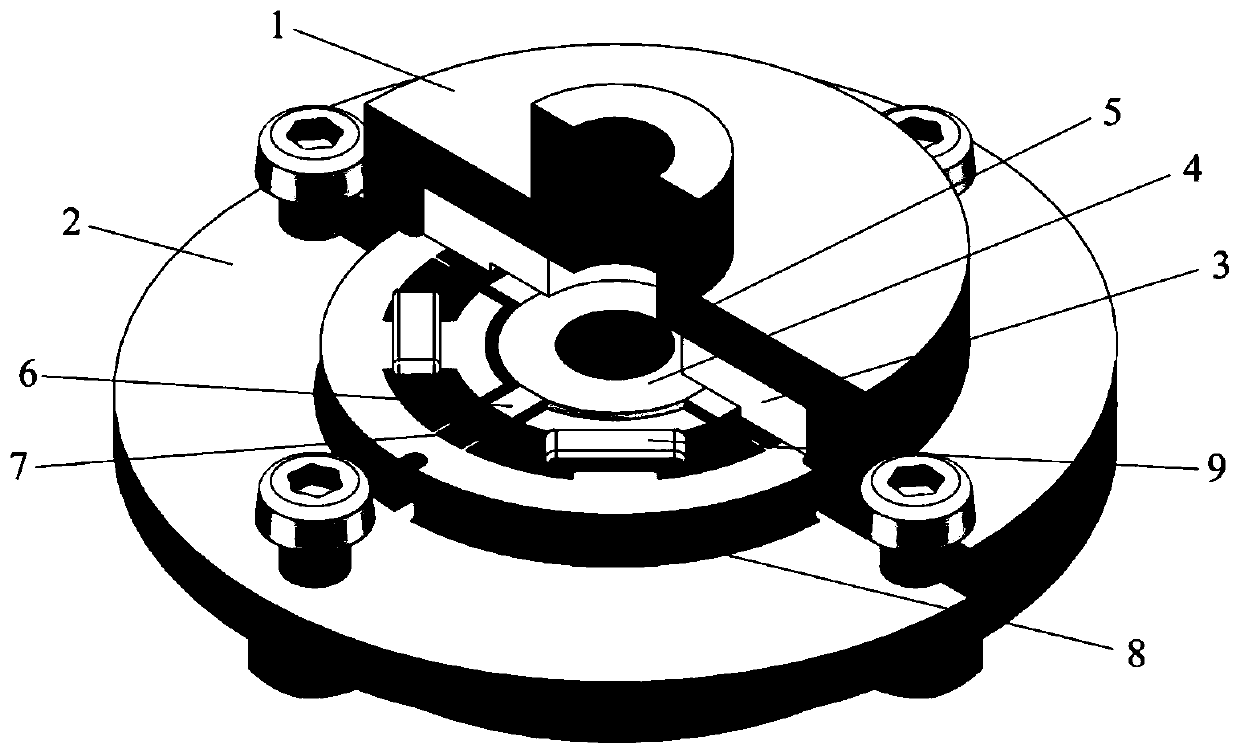

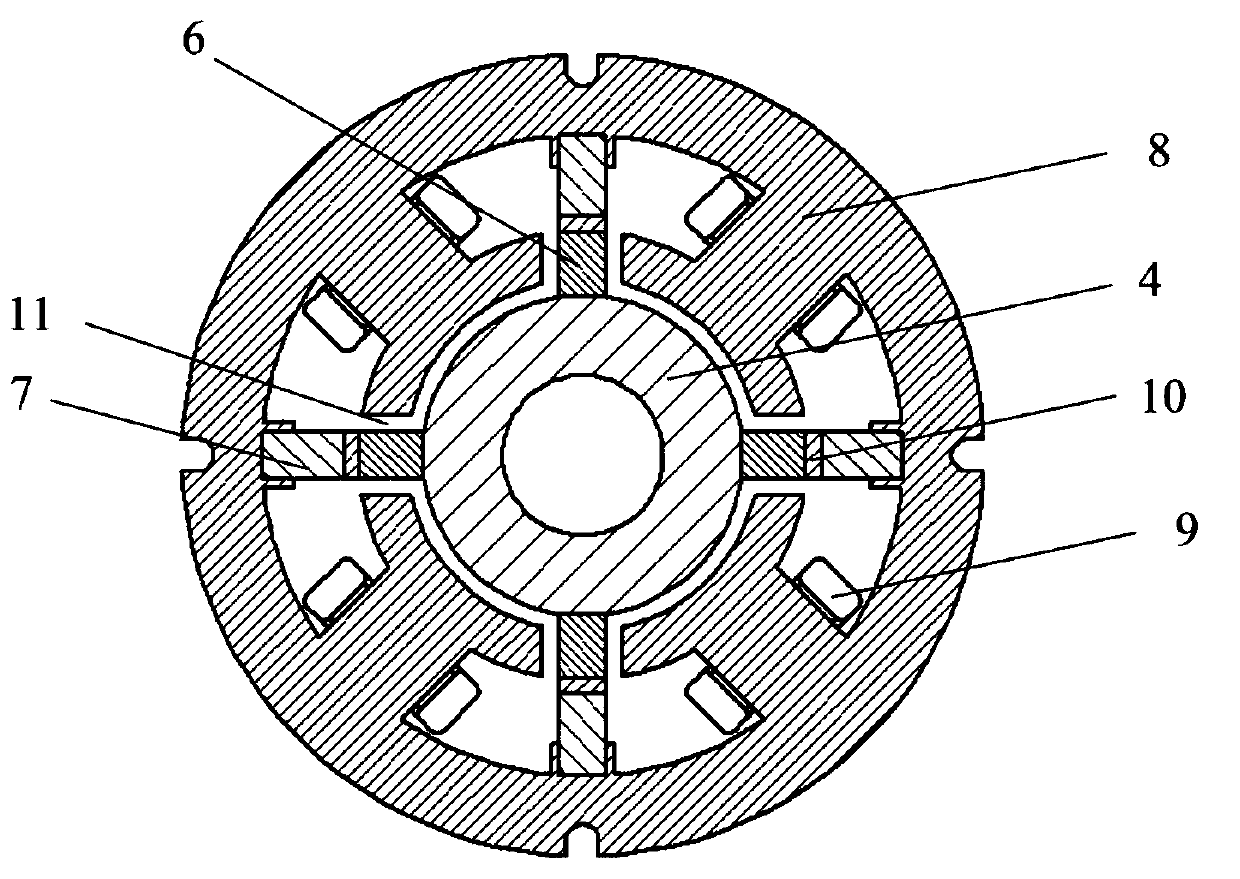

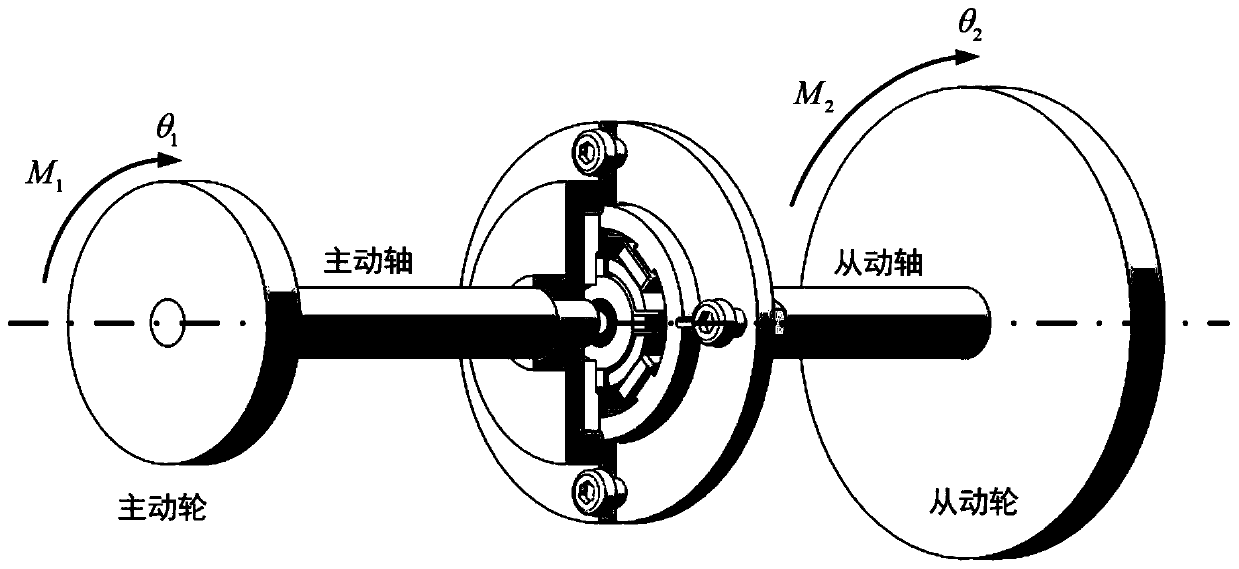

[0017] like figure 1 As shown, a torsional quasi-zero stiffness vibration isolator with adjustable negative stiffness in the present invention includes a front shell 1, a rear shell 2 and a permanent magnet excitation mechanism inside the cavity. Wherein the front shell 1 and the rear shell 2 are fixedly connected by bolts and nuts. The inside of the front housing 1 and the rear housing 2 has a boss along the axial direction, which cooperates with the groove of the annular permanent magnet clamping mechanism 8 inside the permanent magnet excitation mechanism to prevent the permanent magnet excitation mechanism from generating a gap relative to the front housing 1 and the rear housing 2. Rotational movement. Gaskets 3 are installed at the front and rear sides of the permanent magnet excitation mechanism in contact with the front casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com