Briquette replacement device

A technology for briquettes and furnace walls, which is applied in the field of briquettes replacement devices, can solve problems such as coal ash splashing, achieve the effects of reducing the generation of coal slag, facilitating separation and removal, and avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

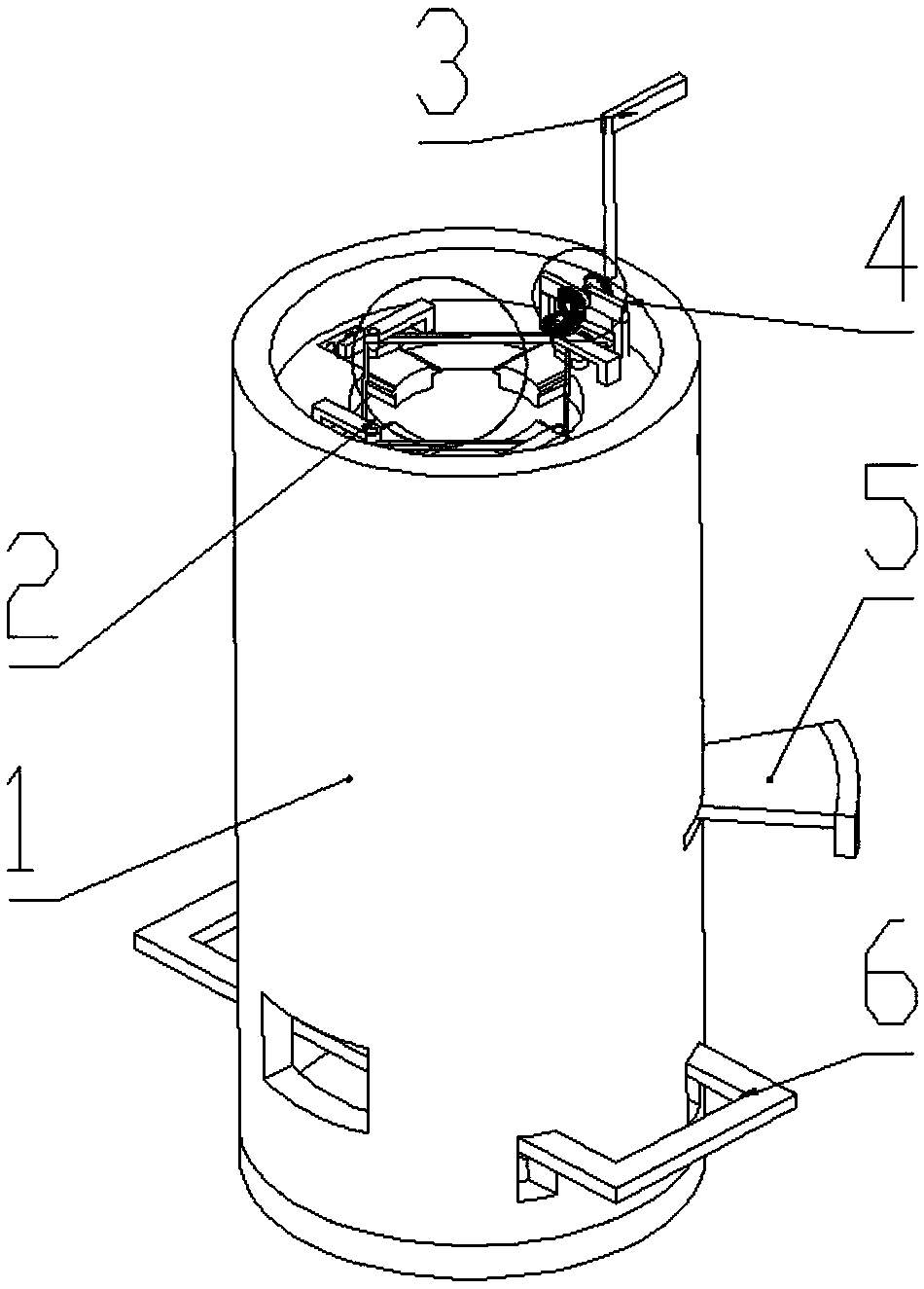

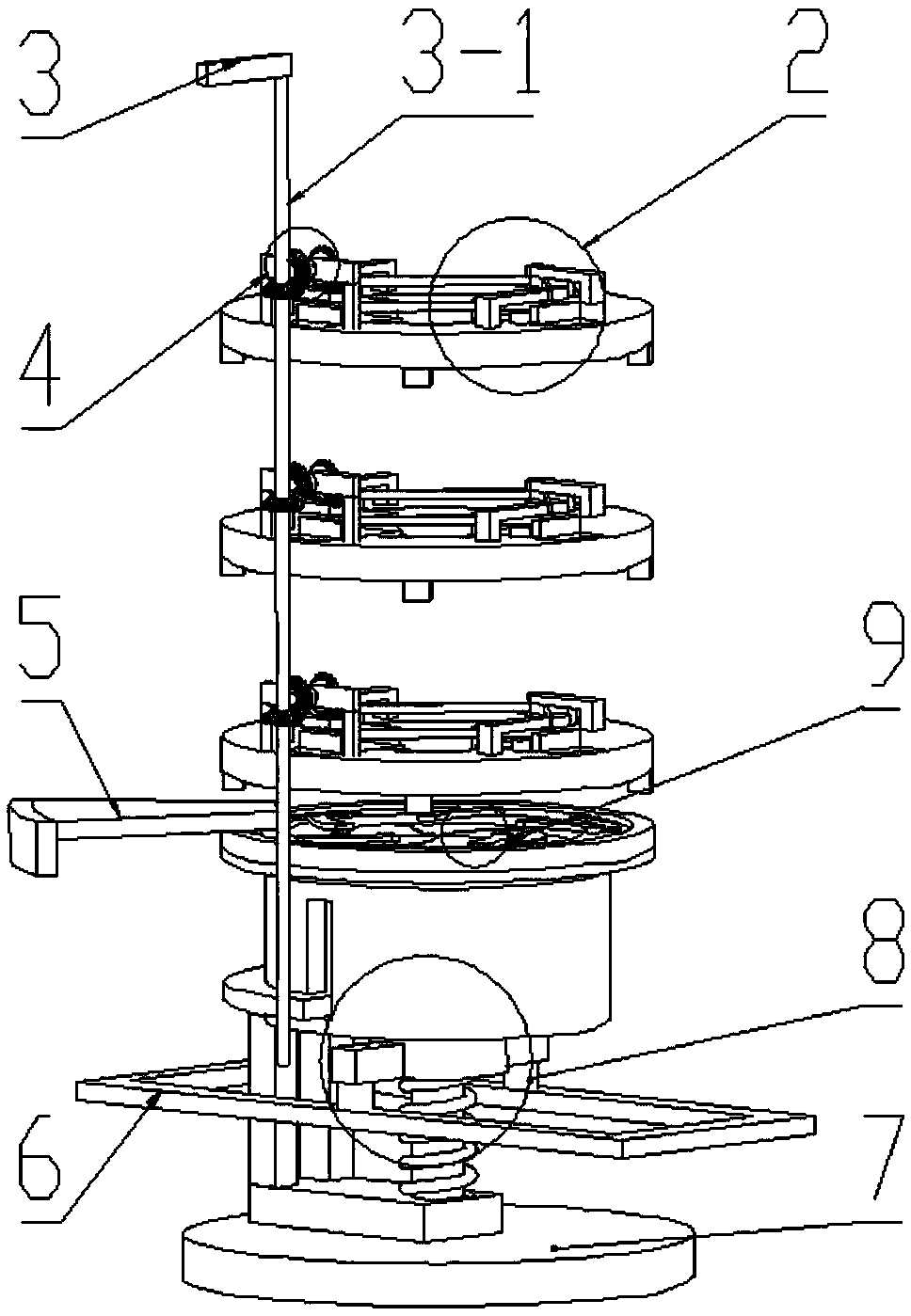

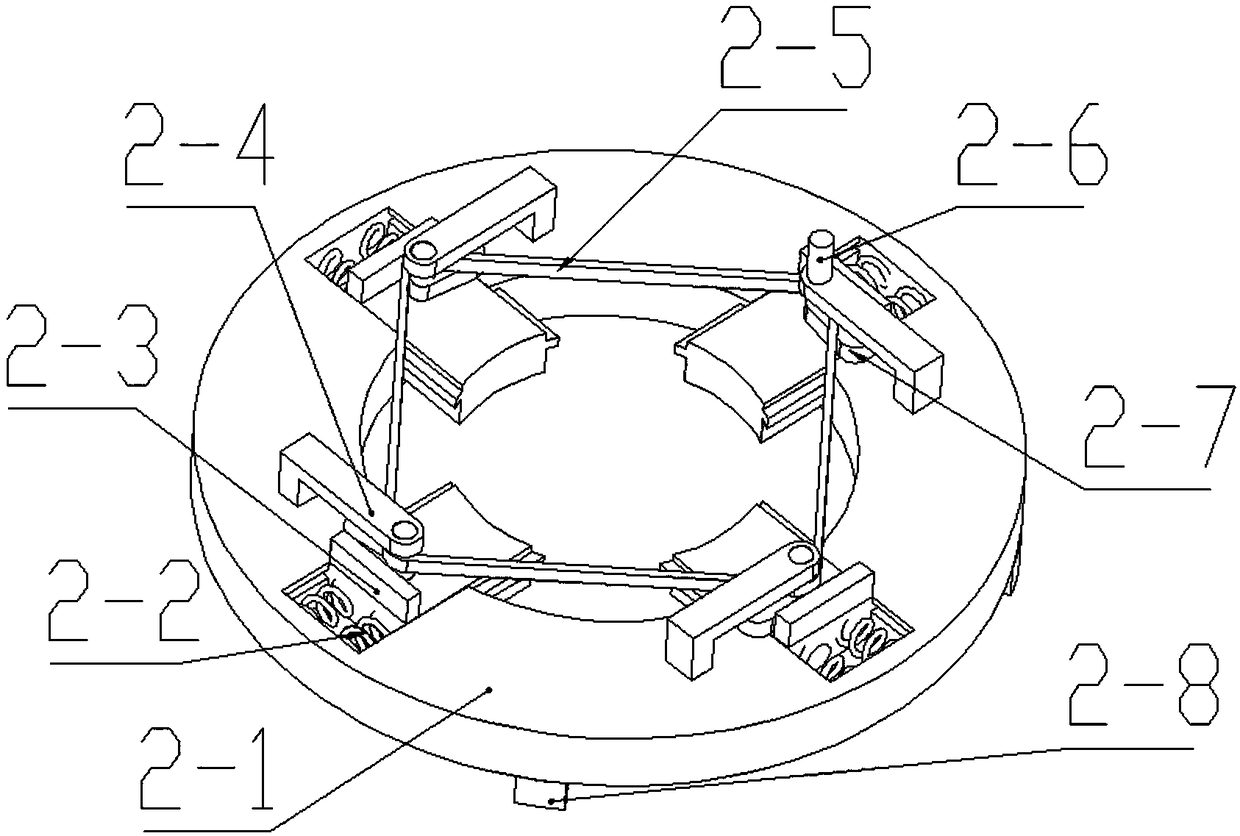

[0059] see figure 1 and figure 2 , a briquette replacement device, comprising a furnace wall cover 1, including several clamping mechanisms 2 arranged downwards from the upper end of the furnace wall cover 1, and a driving mechanism 4 arranged on the furnace wall cover 1 and used to drive the clamping mechanisms 2 to work , the shearing mechanism 9 arranged at the bottom of the furnace wall cover 1 and used to separate the burnt briquettes, the up and down movement mechanism 8 arranged at the lower end of the shearing mechanism 9 and used to remove the burnt briquettes, and the clamping mechanism 2 is arranged on the furnace wall cover 1 On the brackets 2-9 provided on the inner surface, the shearing mechanism 9 is arranged between the clamping mechanism 2 and the up and down movement mechanism 8, and the up and down...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap