Miniaturized insensitiveness detonating tube detonator

A detonator and detonator technology, which is applied in the field of miniaturized insensitive detonator detonators, can solve problems such as poor safety and detonation reliability, achieve safety in use, detonation completeness and reliability, and enhance radial restraint , the effect of reducing the axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing of description, the present invention will be further described.

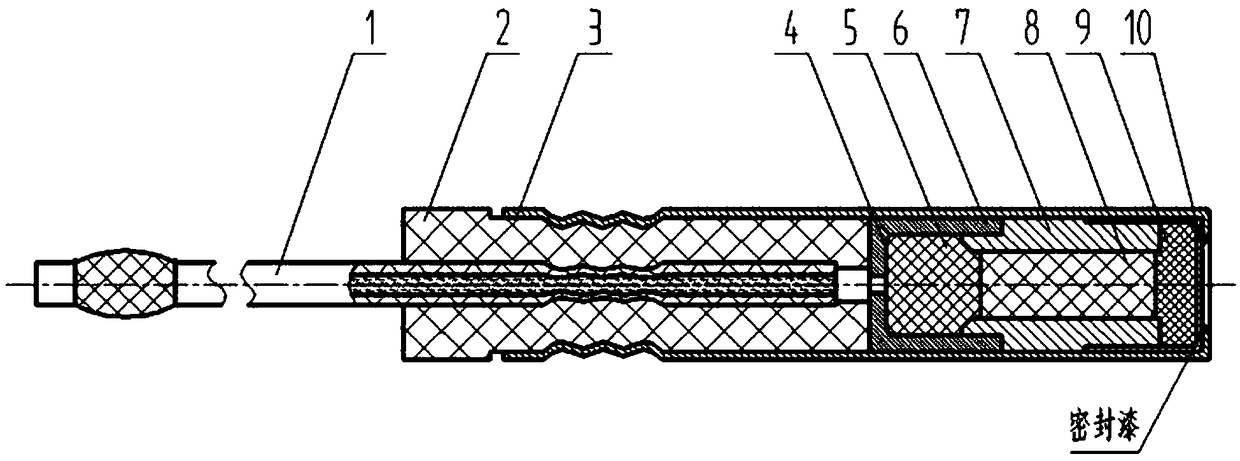

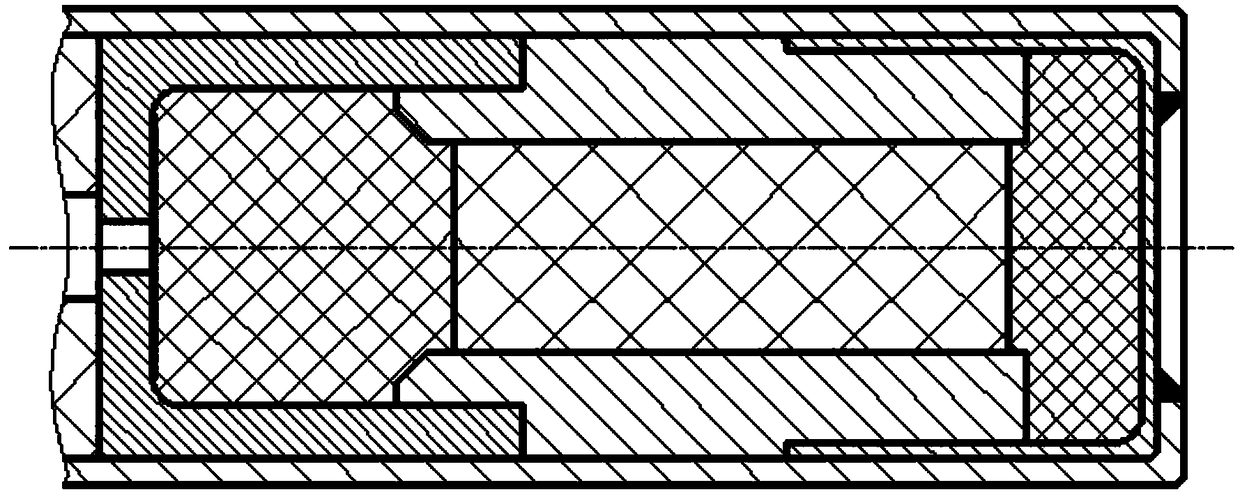

[0019] combine Figure 1-2 , a miniaturized insensitive nonel detonator, comprising a nonel 1, a bayonet plug 2, a shell 3, an ignition powder 5, a cap 6, an inner tube 7, an intermediate charge 8, a bottom charge 9 and a bottom cap 10, The shell 3 is a hollow tubular structure with openings at both ends, the shell 3 includes a top opening and a bottom opening, the bottom outer surface of the bottom cap 10 is close to the bottom inner surface of the shell 3 and the bottom cap The bottom of 10 is limited by the bottom opening of the tube shell 3, the bottom medicine 9 is located at the bottom of the bottom cap 10, the inner tube 7 is arranged on the top of the bottom medicine 9, and the lower part of the inner tube 7 is located at the bottom of the bottom cap 10. In the bottom cap 10, the upper part of the inner tube 7 is located in the cap 6, the intermedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com