Soil moisture monitor for direct-connected vacuum pressure gauge

A vacuum pressure gauge and soil moisture technology, applied in soil material testing, instruments, measuring devices, etc., can solve the problems of inconvenient operation, large volume of the negative pressure gauge, easy air intake of the vacuum pressure gauge, etc. Simple, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

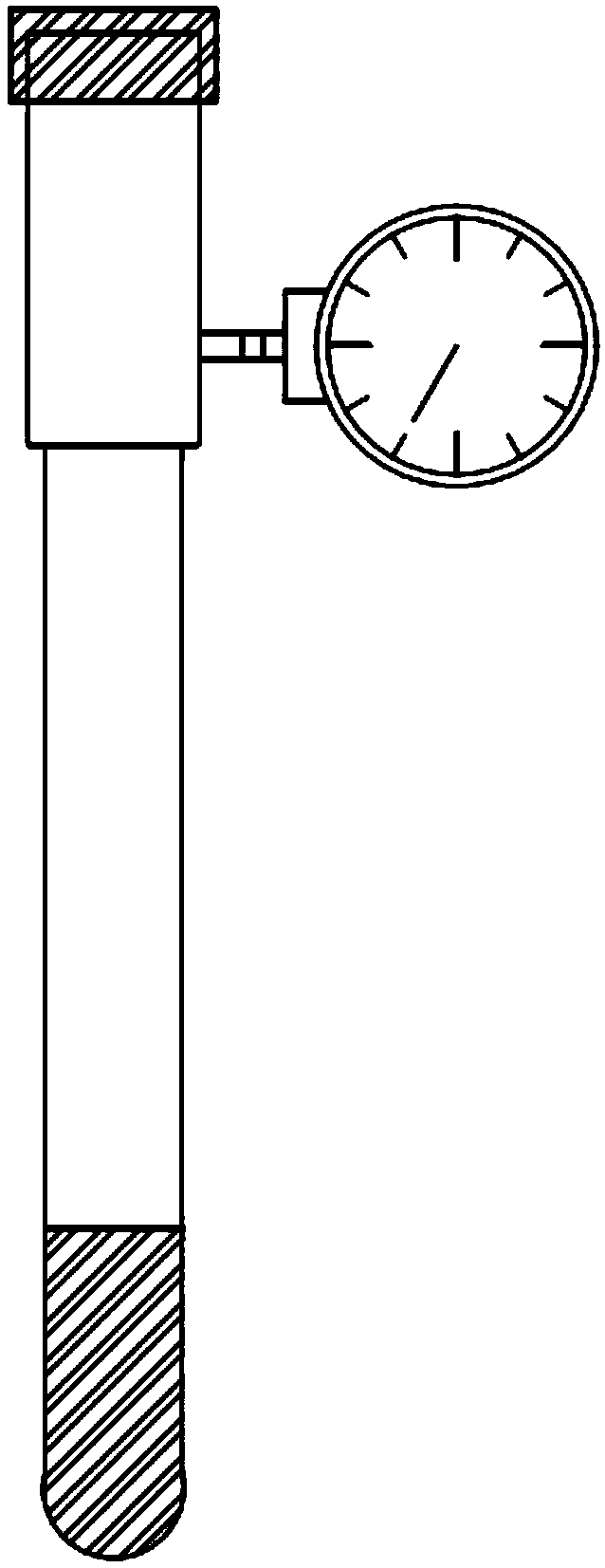

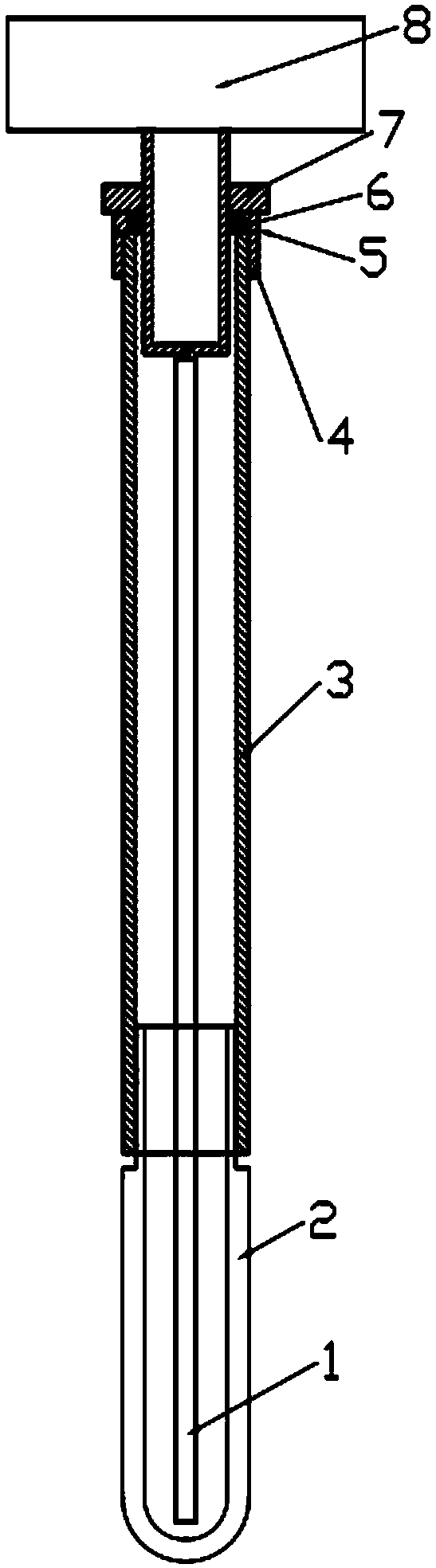

[0025] Such as figure 2 As shown, a soil moisture monitor directly connected to a vacuum pressure gauge includes a vacuum pressure gauge, a sealing device, a plastic hose 1, an air collection chamber 3 and a clay head 2. One end of the chamber 3 is connected, the other end of the gas collection chamber 3 is connected to the clay head 2, one end of the plastic hose 1 is connected to the air inlet of the vacuum pressure gauge, and the other end of the plastic hose 1 Deep into the clay head 2, 1-2cm away from the bottom of the clay head 2. The vacuum pressure gauge is an axial vacuum pressure gauge 8.

[0026] The gas collection chamber 3 is a transparent plastic tube or a plexiglass tube, and the present embodiment adopts a plexiglass tube.

[0027] The sealing device includes a rubber gasket 6 and an inner threaded joint. The inner threaded joint includes a threaded connection part 7, a rubber gasket installation part 5 and an air collection chamber connection part 4. The va...

Embodiment 2

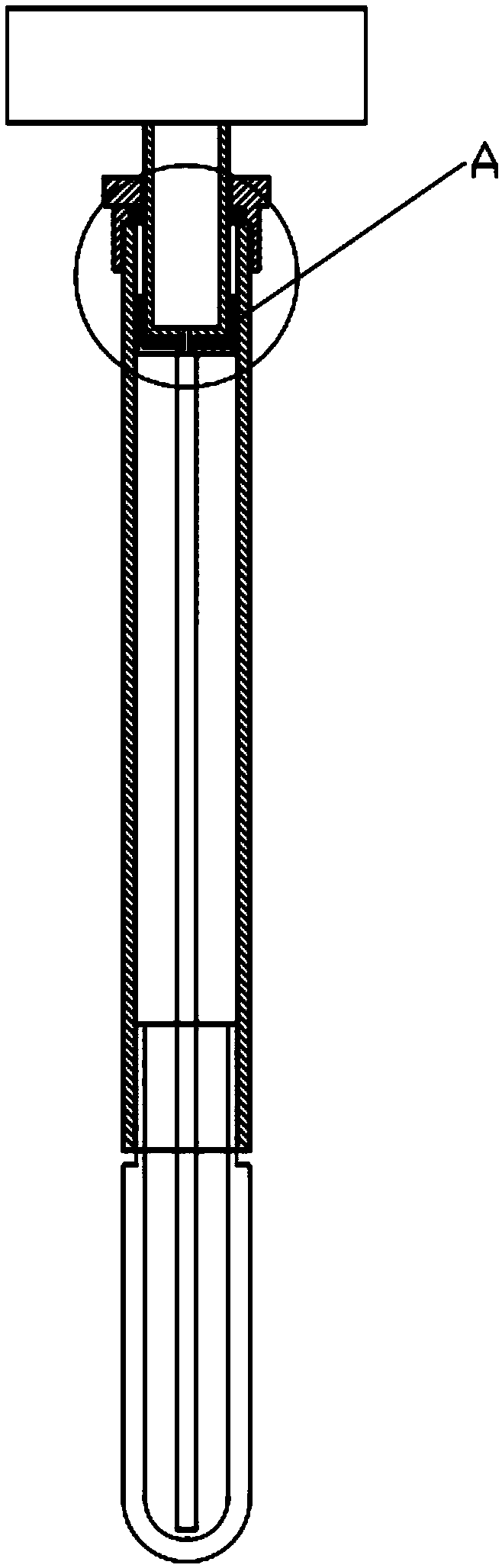

[0030] Such as image 3 and 4 As shown, a soil moisture monitor directly connected to a vacuum pressure gauge includes a vacuum pressure gauge, a sealing device, a plastic hose 1, an air collection chamber 3 and a clay head 2. One end of the chamber 3 is connected, the other end of the gas collection chamber 3 is connected to the clay head 2, one end of the plastic hose 1 is connected to the air inlet of the vacuum pressure gauge, and the other end of the plastic hose 1 Deep into the clay head 2, 1-2cm away from the bottom of the clay head 2. The vacuum pressure gauge is an axial vacuum pressure gauge 8.

[0031] The gas collection chamber 3 is a transparent plastic tube or a plexiglass tube, and the present embodiment adopts a plexiglass tube.

[0032] The sealing device includes a rubber gasket 6 and an inner threaded joint. The inner threaded joint includes a threaded connection part 7, a rubber gasket installation part 5 and an air collection chamber connection part 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com