Agitation tank emptying and output solution concentration keeping disturbance-rejection method with saturation characteristic

A technology of solution concentration and stirring tank, which is applied in the direction of non-electric variable control, simultaneous control of multiple variables, instruments, etc., can solve the problem of excessive deviation between solution concentration and target concentration, and achieve the effect of eliminating local interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

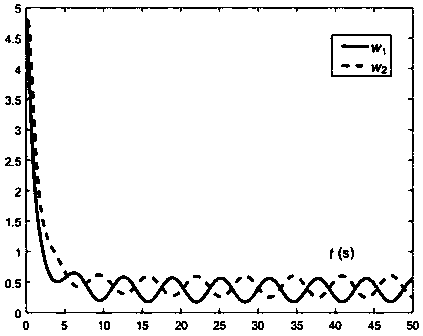

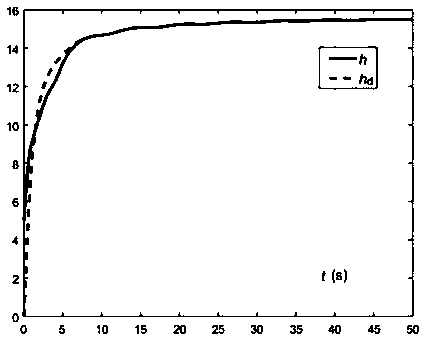

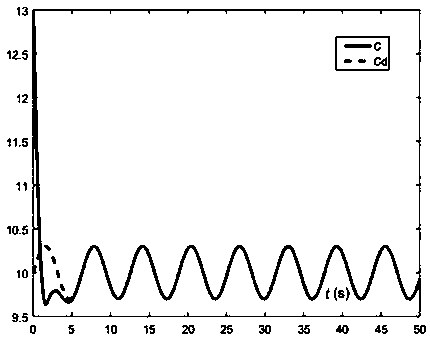

[0036] The present invention will be further described below in conjunction with the accompanying drawings. A kind of anti-disturbance and the method for emptying and maintaining the concentration of the output solution of the stirred tank with saturation characteristics, comprising the steps of:

[0037] 1) Obtain the parameters of the mixing tank, the parameters include the concentrations of the two liquids input into the mixing tank and Current and expected output solution concentration C of the stirred tank bd , C bd =C b (0), the expected trajectory of the liquid level drop in the stirring tank h d (t), where The system equation of the mixing tank is as follows:

[0038]

[0039]

[0040] where k 1 and k 2 In order to affect the outflow rate constant of the dynamic process of the system, h(t) is the height of the liquid level drop in the stirring tank, t is the time, and w 1 (t), w 2 (t) is the flow rate of the two liquids input into the mixing tank, C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com