Pipeline auxiliary inspection system

A technology for pipelines and inspection information, applied in computer-aided design, instrumentation, geometric CAD, etc., can solve the problems of low accuracy and complicated operation of inspection pipelines, so as to avoid memory errors, improve inspection efficiency, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

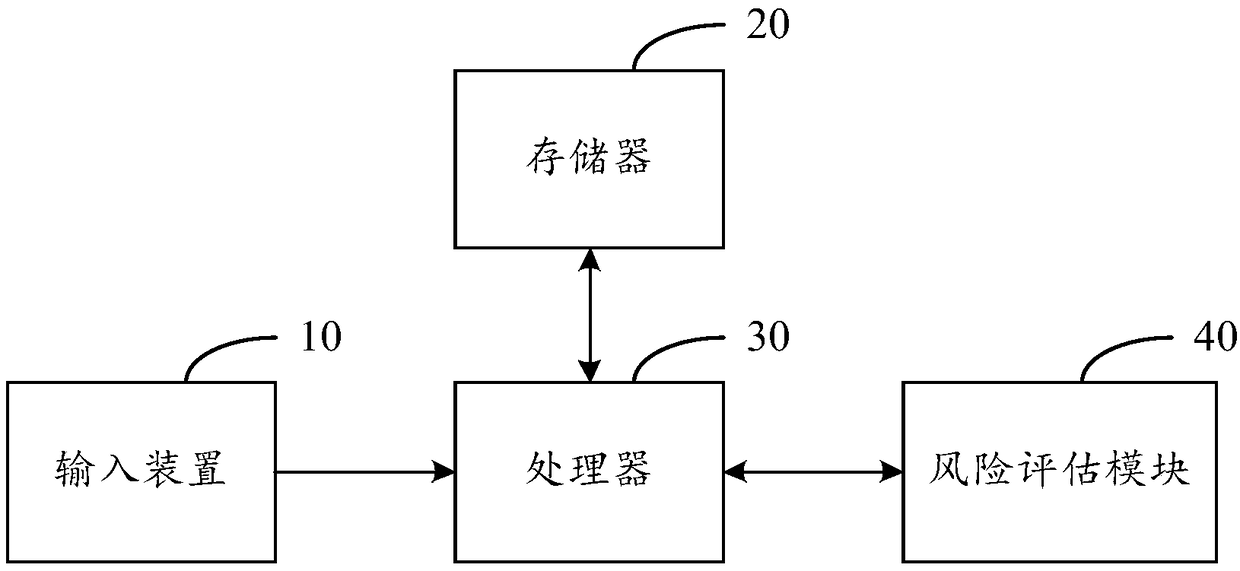

[0054] For a pipeline auxiliary inspection system provided by an embodiment of the present invention, see figure 1 As shown, it includes: an input device 10 , a memory 20 , a processor 30 and a risk assessment module 40 .

[0055] Among them, the input device 10 is used to obtain the pipeline inspection information of the point to be tested input by the user, and send the pipeline inspection information to the processor 30. The pipeline inspection information includes: temperature information, size information, pressure information, pipeline thickness and flaw detection data.

[0056] The memory 20 is used for pre-storing pipeline standard information generated base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com