Optical compensation apparatus applied to panel and operating method thereof

An optical compensation and display panel technology, applied in static indicators, instruments, etc., to improve visual experience, correct uneven color defects, and avoid abnormal bright spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

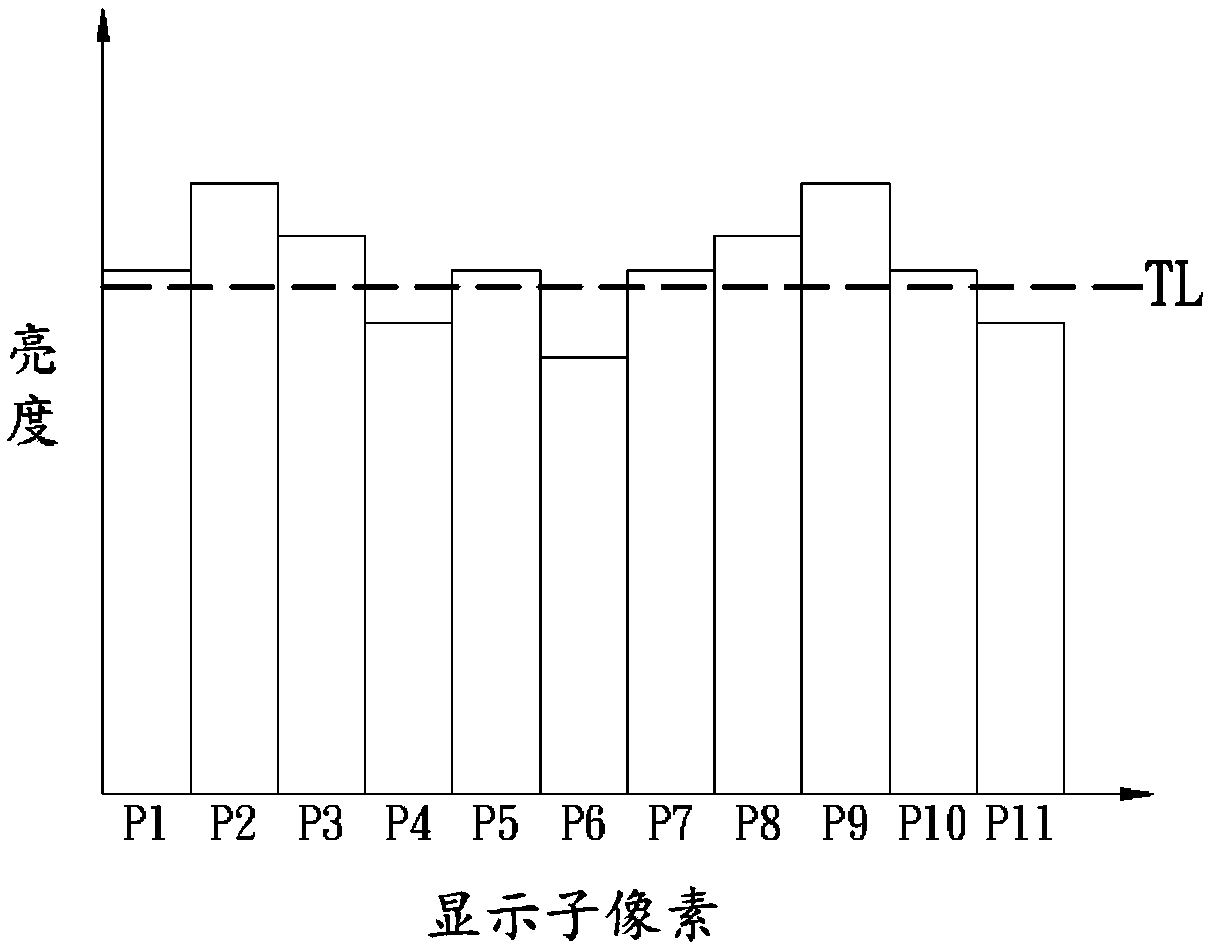

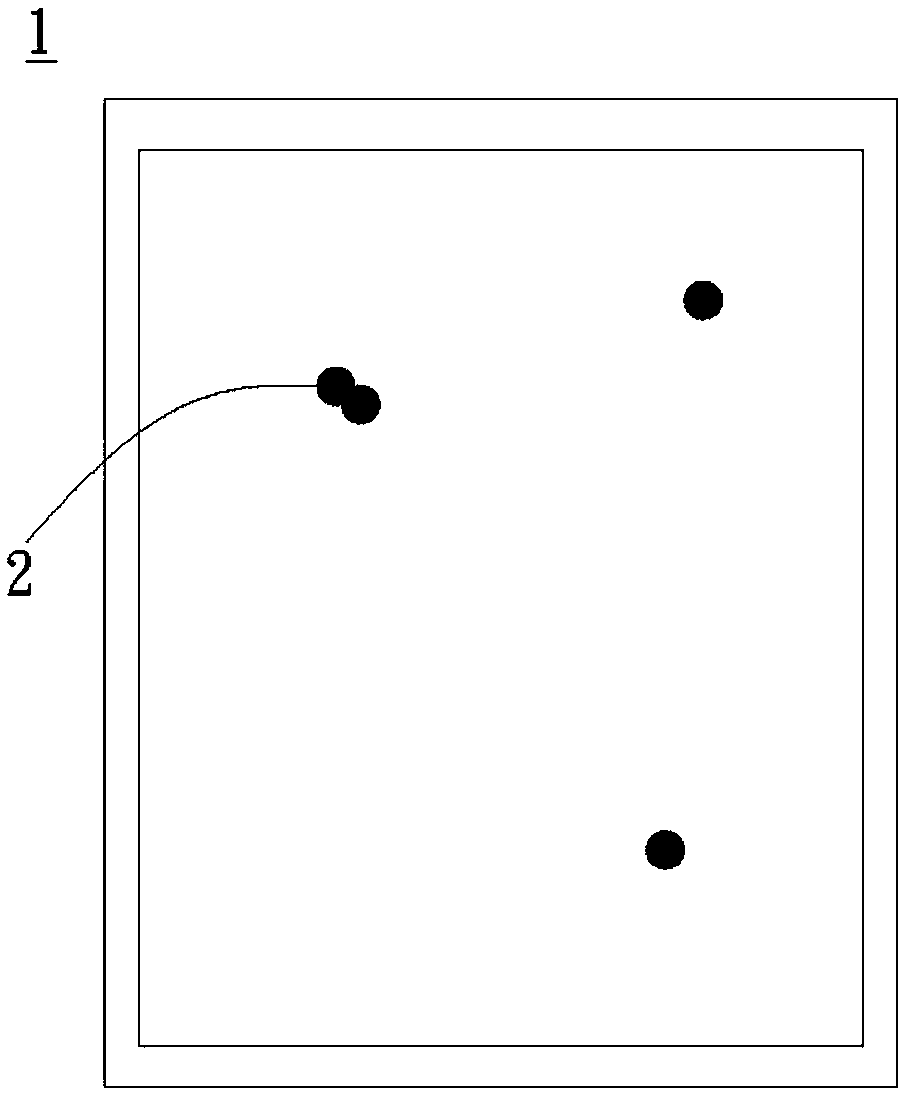

[0067] The invention discloses an optical compensation device and its operation method. In the process of measuring the brightness of all display sub-pixels of a display panel, even if there is dust or other disturbances on the display panel, the optical compensation device and its operation method of the present invention The method will first automatically detect these abnormal display sub-pixels and deal with them appropriately, so as to achieve the effect of color unevenness defect correction (Demura), and can effectively prevent the partial display of the display panel due to wrong optical compensation Unusual bright spots appear in sub-pixels.

[0068] A preferred embodiment of the present invention is an optical compensation device. In this embodiment, the optical compensation device is applied to a display panel, such as an organic light emitting diode (OLED) display panel, but not limited thereto. The display panel includes a plurality of display sub-pixels for displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com