Combined transparent roller assembly

A combined type and roller technology, applied in the field of color sorters, can solve the problems of reducing the working efficiency of the color sorter and the difficulty of accurately collecting color signals by the camera, so as to achieve the effect of ensuring reliability and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

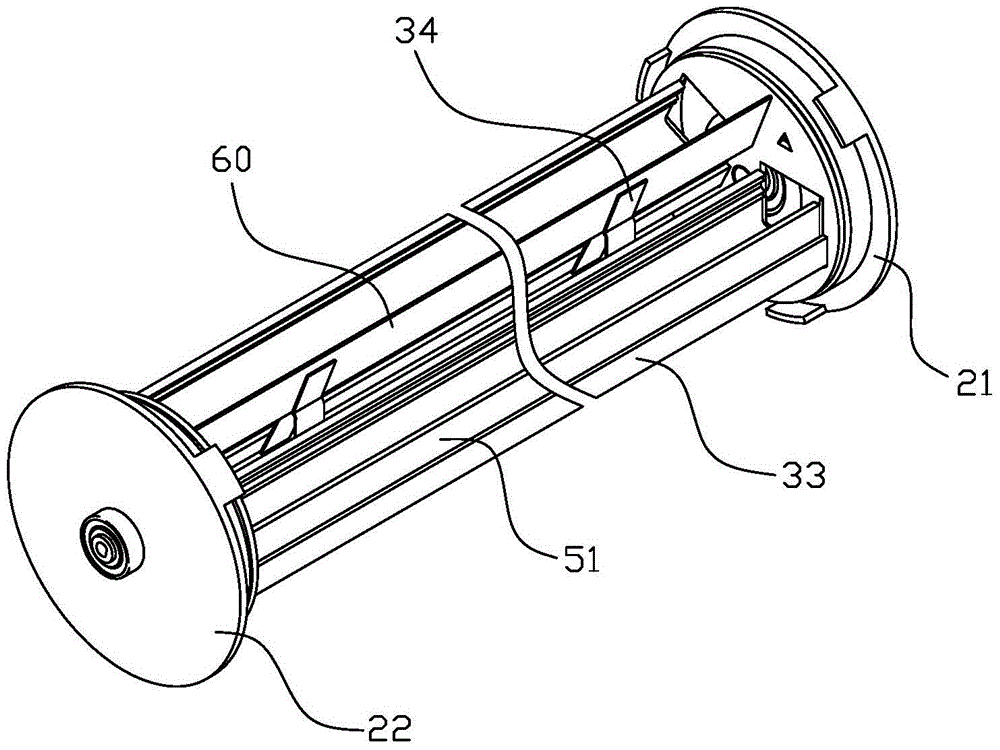

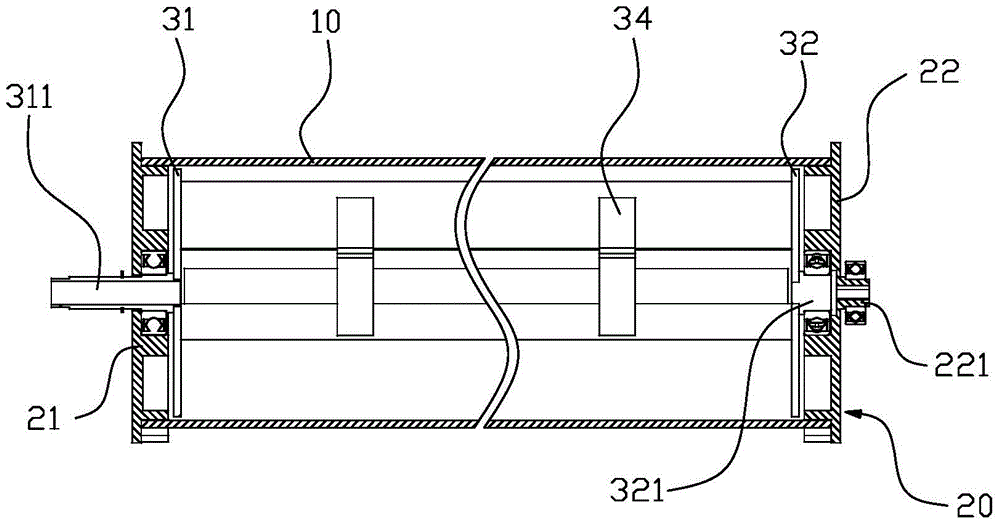

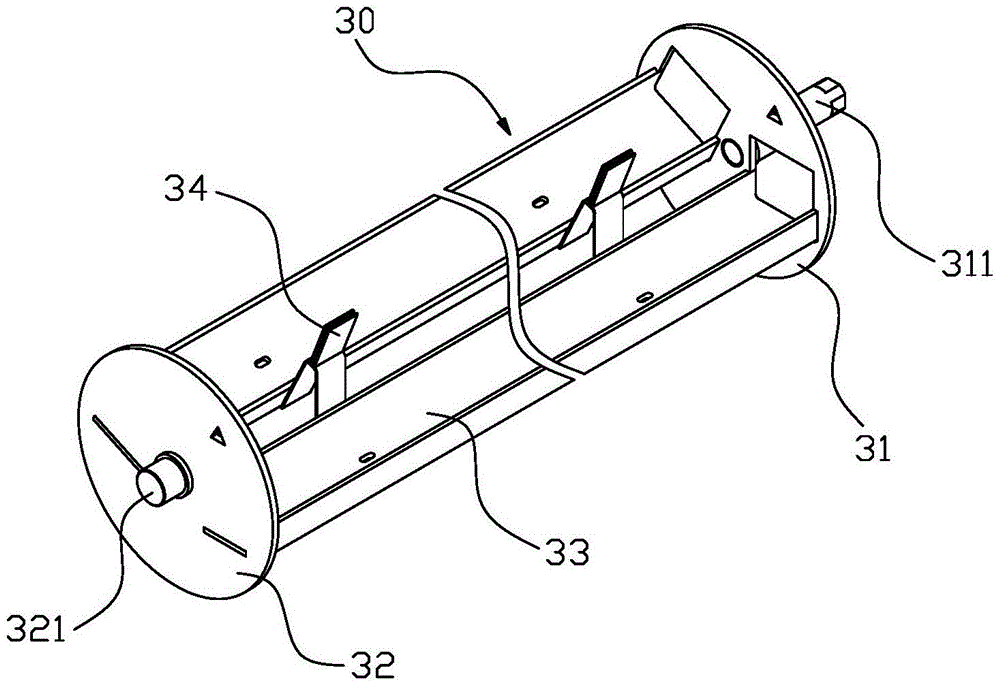

[0011] Combine below Figure 1 to Figure 4 , the present invention is described in further detail.

[0012] refer to Figure 1-4 , a combined light-transmitting roller assembly, including a cylindrical light-transmitting roller 10, the light-transmitting roller 10 is connected to the drive unit through a roller bracket 20, and the cavity of the light-transmitting roller 10 is provided with The fixed bracket 30 is fixedly connected with the color sorter, the light source unit 40, the background unit 50 and the isolation plate 60 are all arranged on the fixed bracket 30, and the isolation plate 60 is located between the light source unit 40 and the background unit 50 for isolating the light emitted by the light source unit 40. The light is reflected by the transparent roller 10 onto the background unit 50 . Both the light source unit 40 and the background unit 50 are arranged in the light-transmitting roller 10 , and when the driving unit drives the light-transmitting roller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com