High-speed scanner

A scanner and high-speed technology, applied in the field of high-speed scanners, can solve the problems of ordinary scanners, such as the reduction of precision, the limitation of graphic scanning technology, and the great impact on scanning accuracy, so as to ensure quality reliability and stability, reliable scanning quality, Obvious effect of speed advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

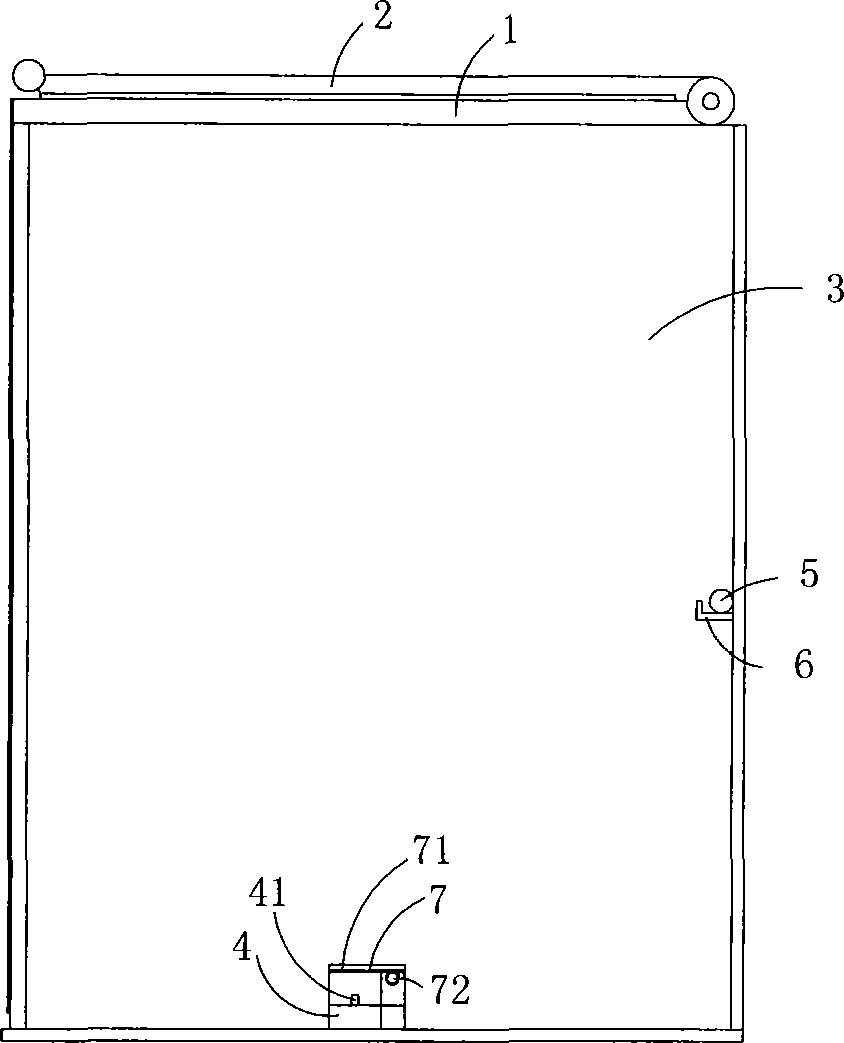

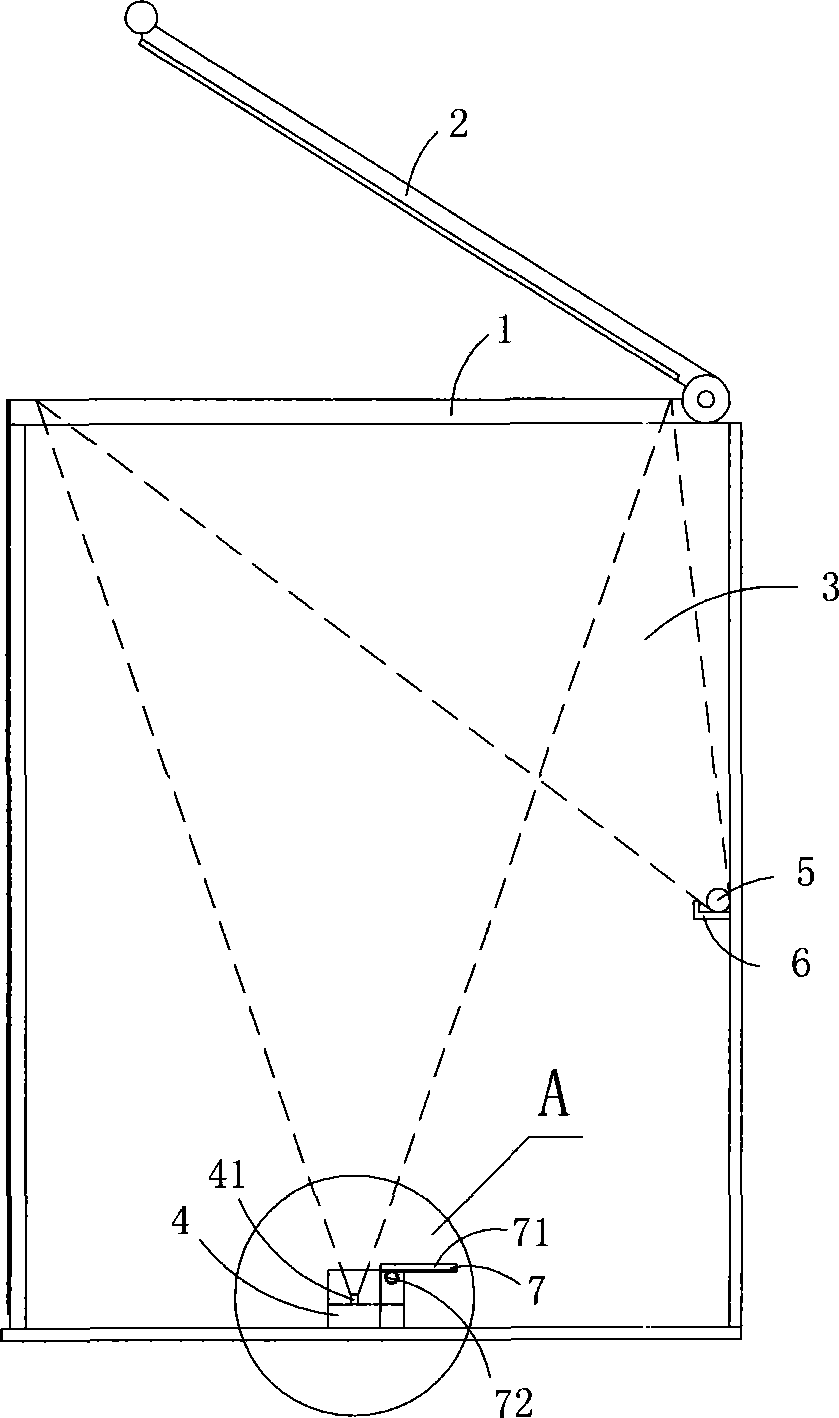

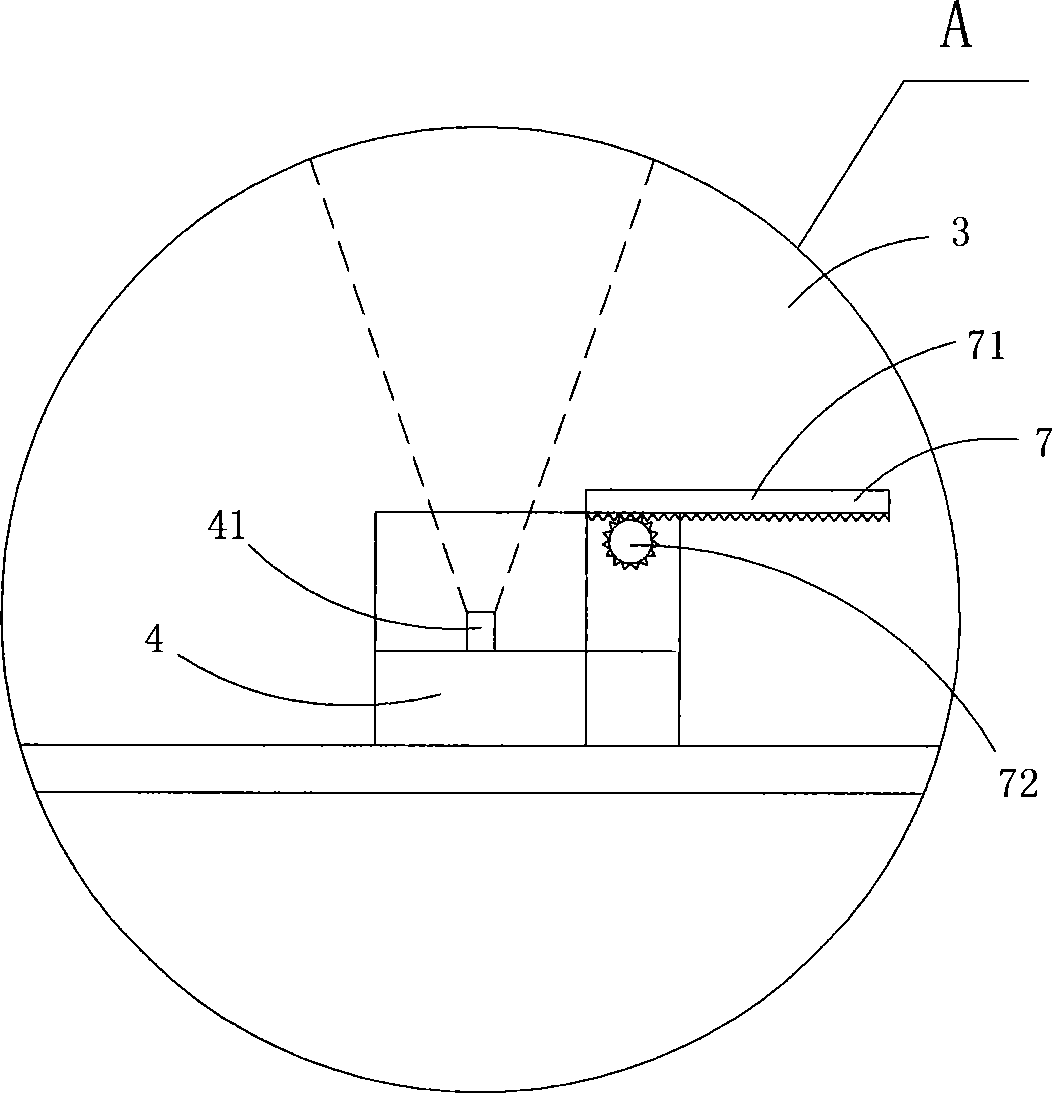

[0033] figure 1 and figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 A structural schematic diagram of the platen in the high-speed scanner shown in an open state; image 3 Yes figure 2 The partial enlarged schematic diagram of A in the high-speed scanner shown.

[0034] The present embodiment is a flatbed high-speed scanner, see Figure 1 to Figure 3 , including a transparent plate 1 for placing documents to be scanned and a platen 2 for pressing documents to be scanned, see figure 2 , the pressure plate 2 is rotatably arranged above the transparent flat plate 1 through a pin shaft; a cavity 3 is provided below the transparent flat plate 1 to facilitate light travel, and a side wall at the bottom of the cavity 3 is provided with a A digital camera main body 4 for one-time imaging. The digital camera body 4 includes a lens element 41, an electronic shutter...

Embodiment 2

[0044] Figure 4 It is a partial structural diagram of the second structure of this embodiment, showing the second specific implementation manner of this embodiment.

[0045] This embodiment is basically the same as Embodiment 1, except that: the drive motor (72) drives the lens cover (71) to rotate at a certain angle through the rotating shaft; the lens cover (71) covers the Or exposing said lens element (41).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com