Wire harness fixing clasp assembly

A buckle assembly and wiring harness fixing technology, which is applied to electrical components, vehicle components, circuits or fluid pipelines, etc., can solve the problems of waste of resources, extremely high accuracy requirements for wiring harness fixing positions, and inability to adjust the buckle position of cable ties, etc. , to achieve the effect of improving versatility and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention are described in detail below, and examples of the embodiments are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

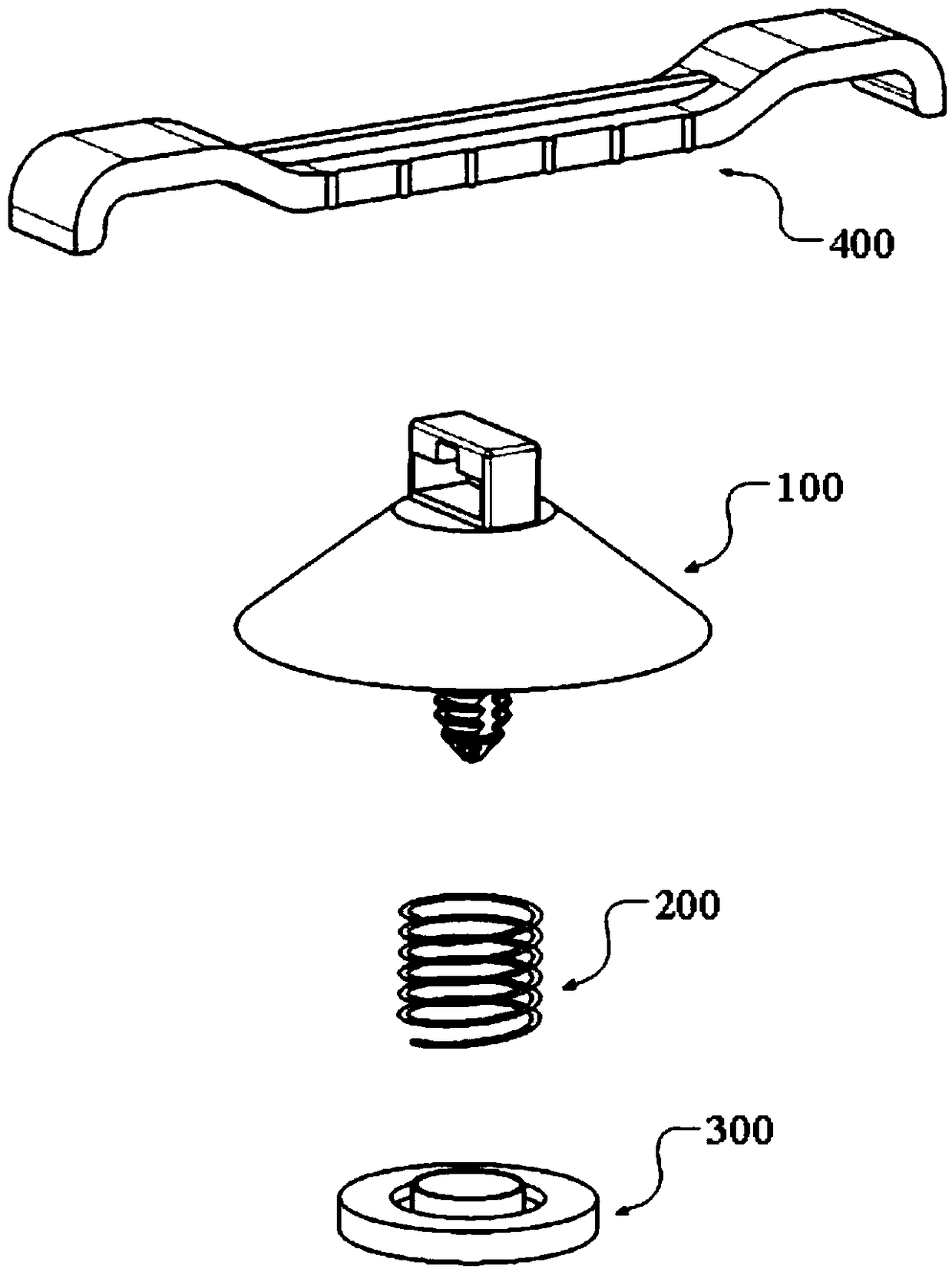

[0039] Please refer to figure 1 , the wire harness fixing buckle assembly provided by the embodiment of the present invention includes a buckle 100 , a spring 200 and a pressing ring 300 .

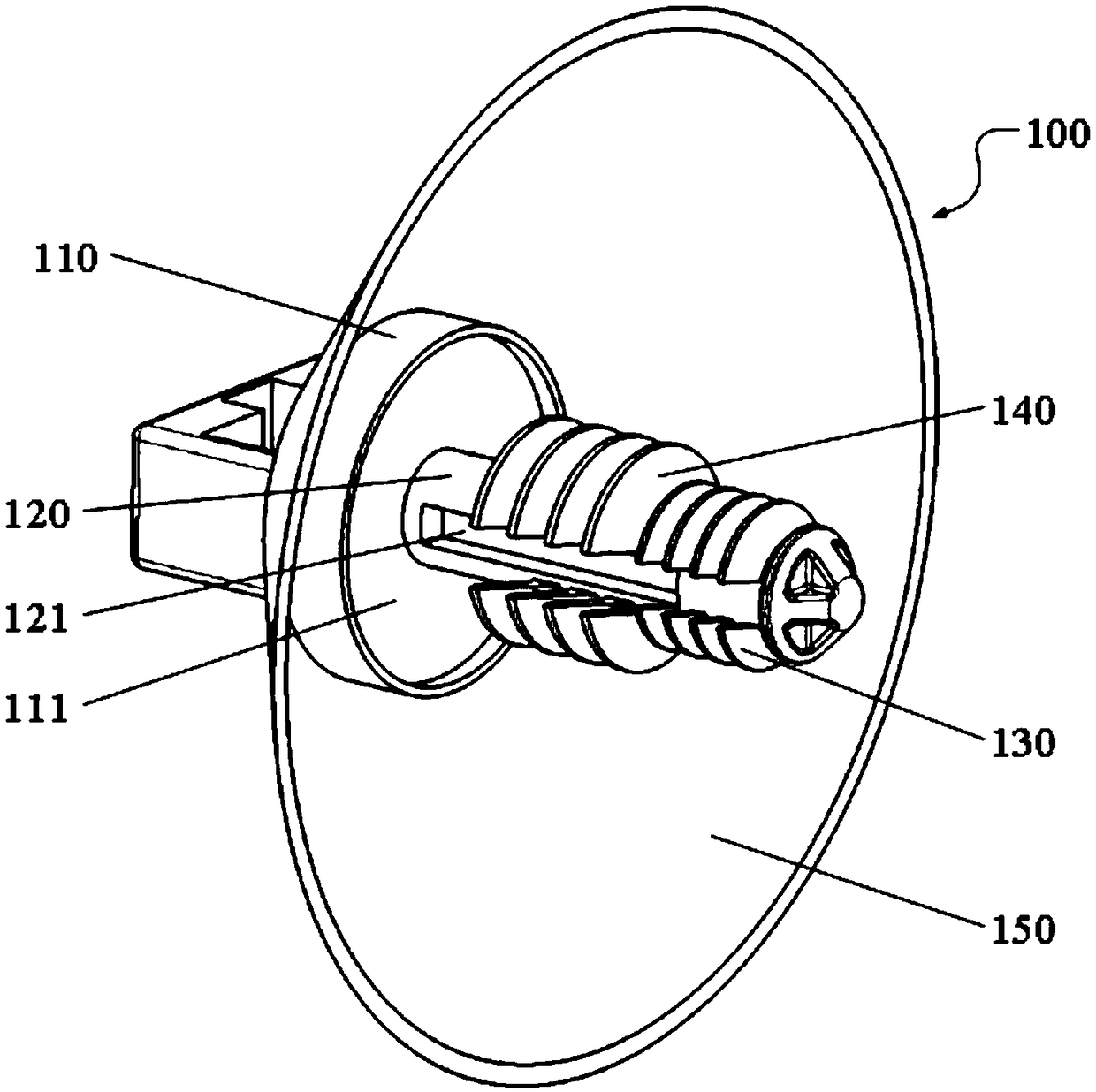

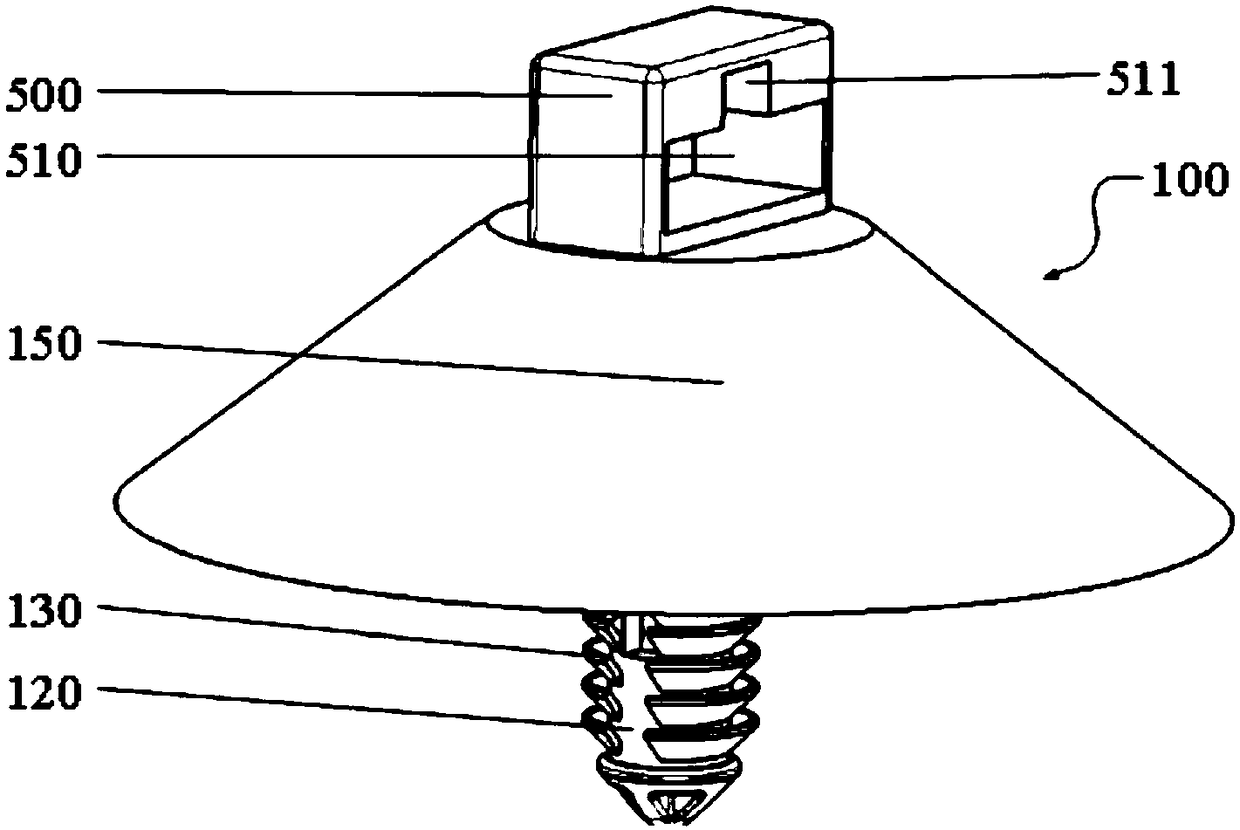

[0040] Among them, please refer to figure 2 , the buckle 100 includes an end cover 110, a post 120, a first elastic piece 130 and a second elastic piece 140; the post 120 is fixedly connected to the end cover 110; the first elastic piece 130 is fixedly connected to one end of the post 120, and the second elastic piece 140 It is fixedly ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap