Correction method for output torque of permanent magnet synchronous motor affected by temperature

A permanent magnet synchronous motor, output torque technology, applied in the control of generators, motor control, motor-generator control and other directions, can solve the problems of limited computing power, complex algorithms, affecting the computing efficiency of the on-board controller single-chip microcomputer, etc., to achieve a simple algorithm , Improve the load rate and ensure the effect of control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The method for correcting the output torque of the permanent magnet synchronous motor affected by the temperature of the present invention comprises the following steps:

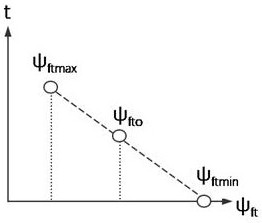

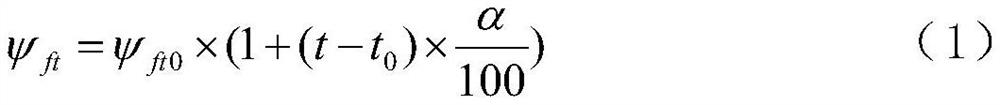

[0044] Step 1. Measure the normal temperature t 0 The flux linkage value ψ of the rotor permanent magnet of the lower motor ft0 , according to the known formula (1) of the flux linkage and temperature of the permanent magnet of the rotor, calculate the minimum temperature t within the operating range of the motor min and the maximum temperature t max The flux linkage value ψ of the rotor permanent magnet of the lower motor ftmin 、ψ ftmax ;

[0045]

[0046] Where: ψ ft is the flux linkage value at the measured temperature, t is the measured temperature, t 0 is the normal temperature, and α is the coefficient;

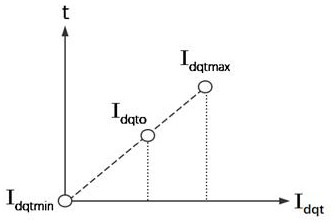

[0047] Step 2, respectively at the lowest temperature t min , room temperature t 0 and the maximum temperature t max Calibrate the motor at the ambient temperature, draw three I d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com