Brewing and drinking machine

A technology of drinking machines and machine casings, applied in the field of beverage brewing, which can solve the problems of hot water overflow, electronic components soaked in water circuits, and the inability to know the real-time status of the inner packaging container of the drinking machine, etc., and achieve the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] A further description will be given below with reference to the drawings and the preferred embodiments of the present invention.

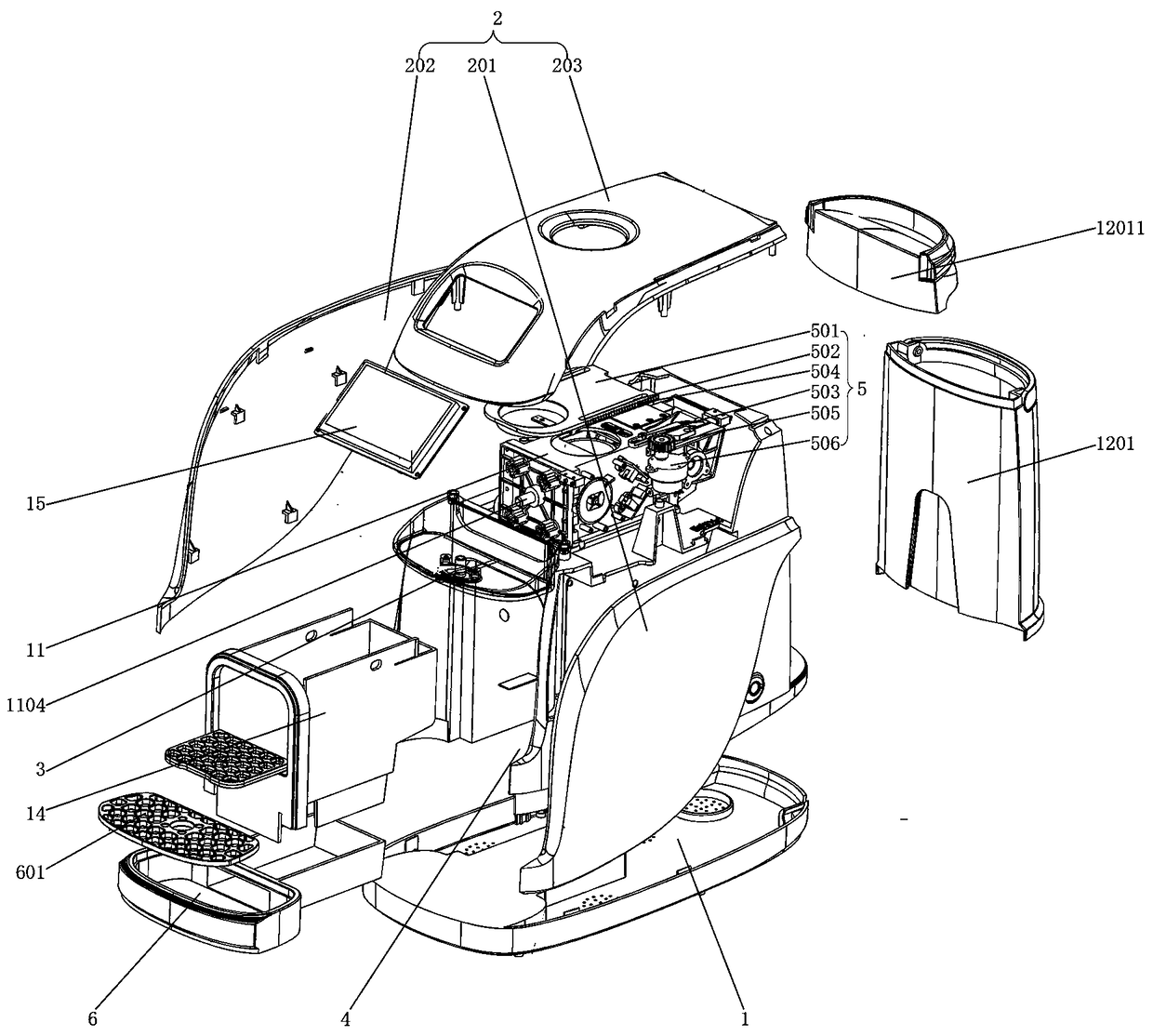

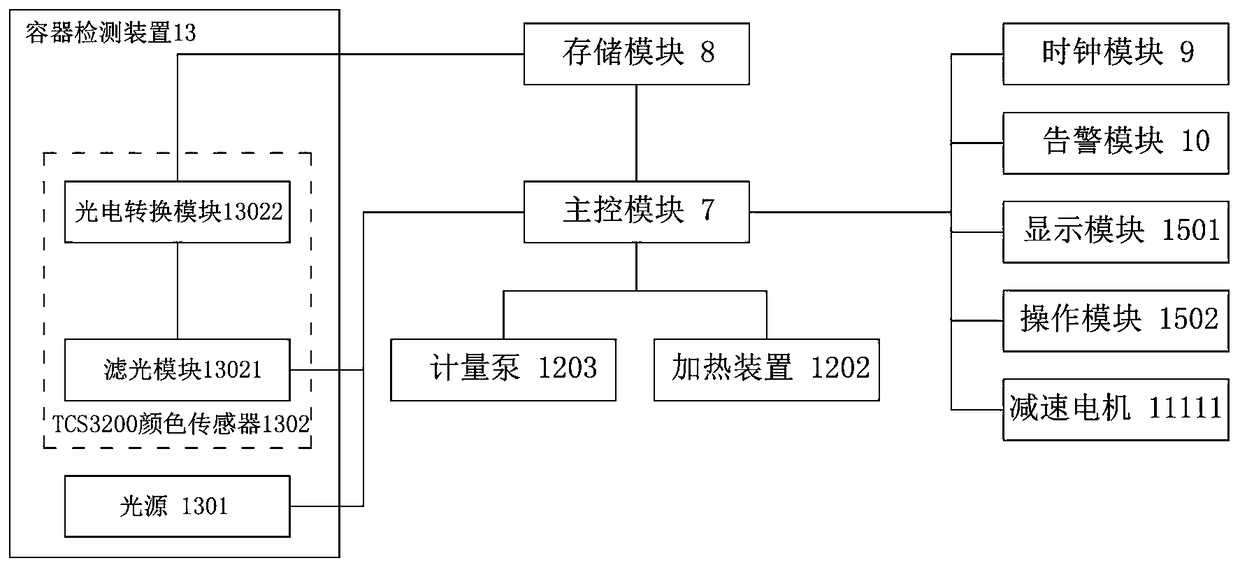

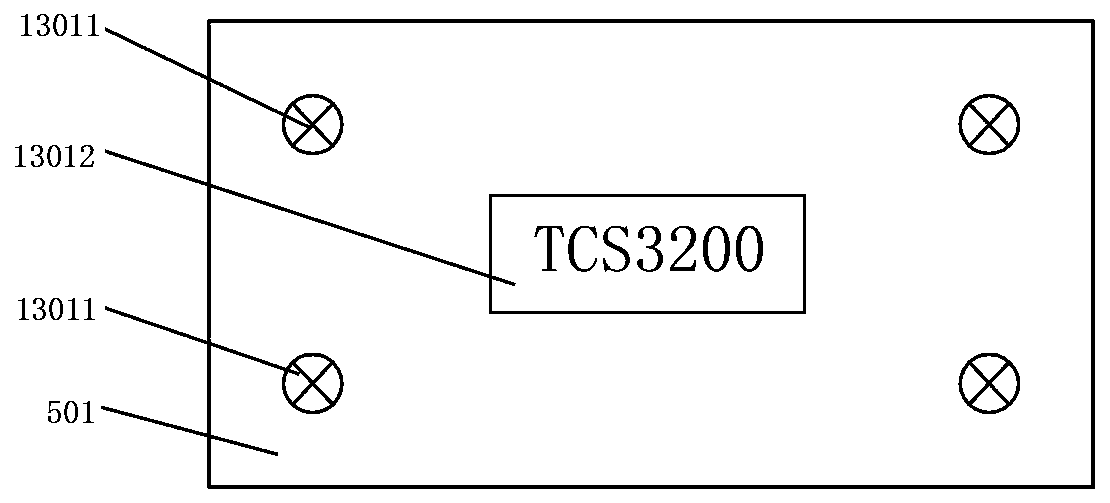

[0053] Such as Figure 1 to Figure 2 As shown, a brewing machine includes a base 1 and a casing 2. The casing 2 is arranged on the base 1. The casing 2 includes a left side plate 201, a right side plate 202 and an upper cover plate 203. The casing 2 The front part is provided with a liquid outlet 3, and an inner cavity 4 is formed inside the casing 2; a cover door 5 is provided on the upper cover plate 203, and the cover door 5 adopts a sliding plate 501 with a sliding groove 502, and is fixedly arranged in the inner cavity 4. There is a positioning block 503 in the sliding groove 502 and matching the sliding groove 502. The sliding plate 501 has a rack 504 on the side. The gear 505 is driven by the motor 506 to mesh with the rack 504, so that the sliding plate 501 is in the sliding groove 502. The positioning block 503 performs translational ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com