Shakeout machine with convenient casting collecting

A shakeout machine and casting technology, which is applied in the field of shakeout machines, can solve problems such as long time consumption, high energy consumption, and unfixed casting positions, and achieve the effects of saving production costs, saving collection time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

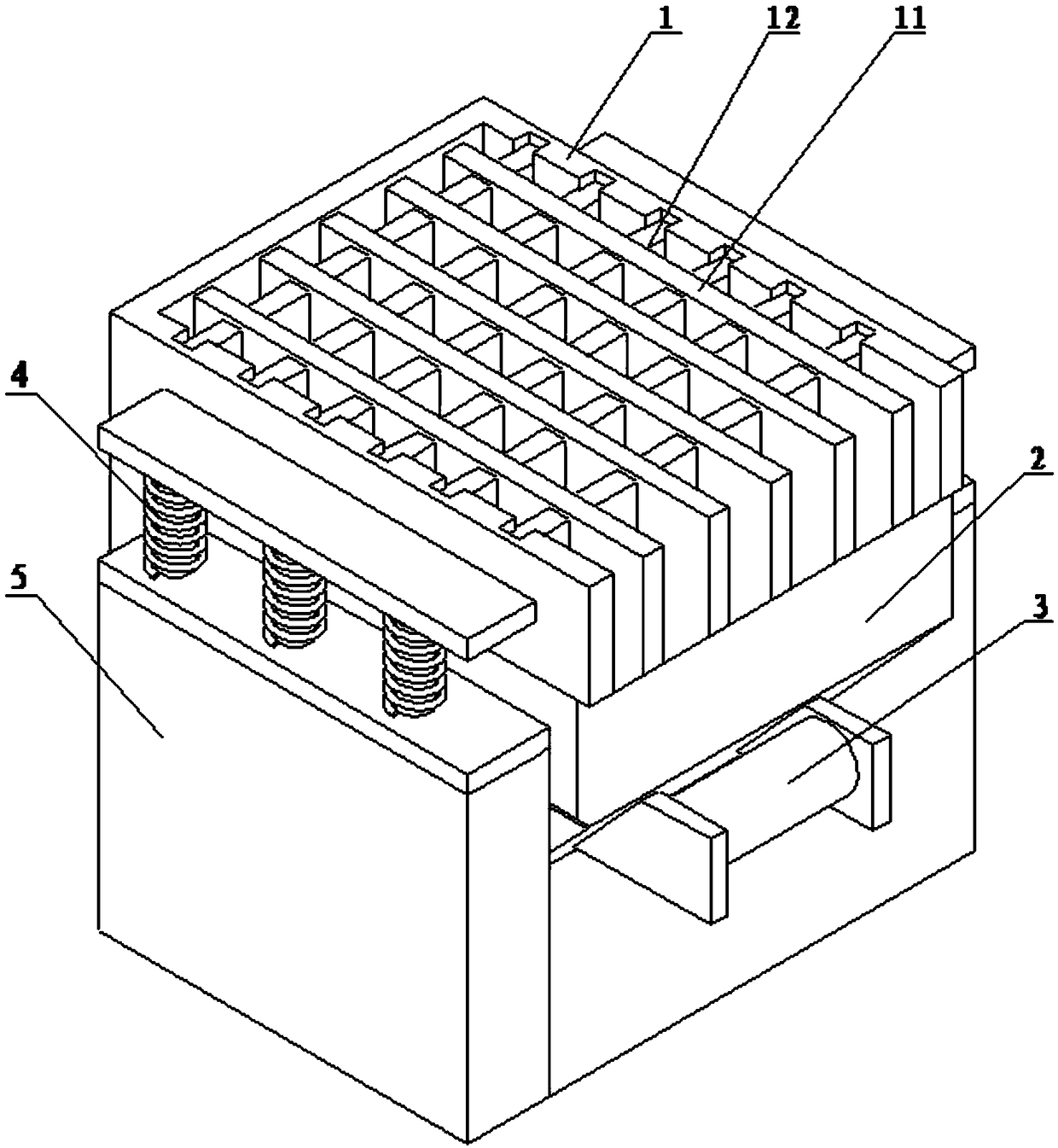

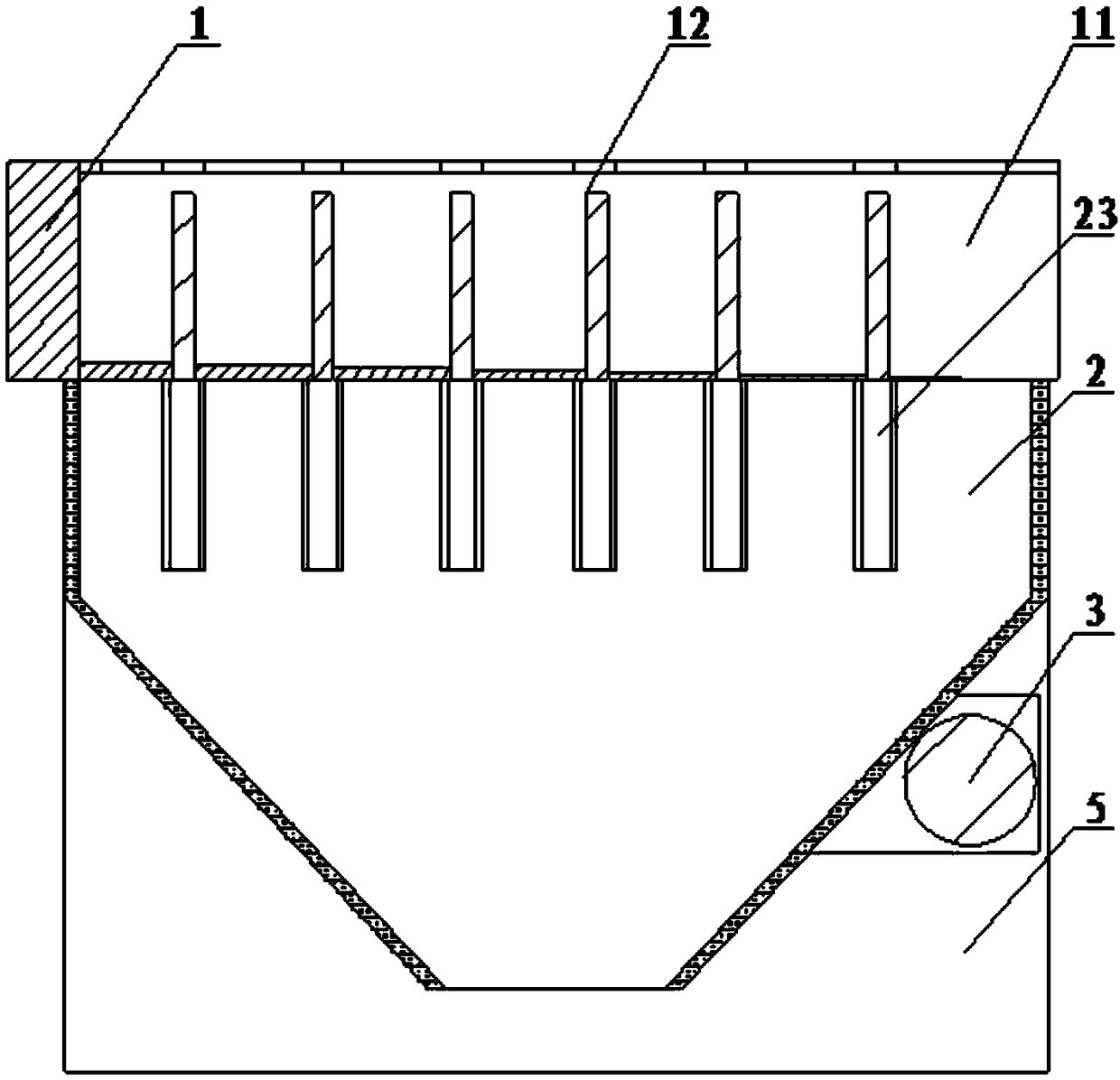

[0038]A shakeout machine for easy collection of castings, comprising a shakeout machine table 1, a sand collection bucket 2, a vibration motor 3, a spring 4 and a machine base 5; the sand collection bucket 2 is arranged below the shakeout machine table 1, and The base is connected to the shakeout machine table 1 through a spring 4, and the vibration motor 3 is arranged on the sand collecting bucket 2;

[0039] The shakeout machine table 1 is a cuboid structure with a side opening, and the shakeout machine table 1 has no top plate, and the bottom plate of the shakeout machine table 1 is uniformly provided with mesh holes, and the shakeout machine bottom plate is arranged obliquely. Fixed grids 11 parallel to each other are fixed on the bottom plate, movable grids 12 perpendicular to the fixed grids 11 are installed on the base, and the movable grids 12 and the fixed grids 11 are open at the contact points;

[0040] The upper part of the sand collection bucket 2 is a hollow cubo...

Embodiment 2

[0043] Embodiment two of the invention is:

[0044] A shakeout machine for easy collection of castings, comprising a shakeout machine table 1, a sand collecting bucket 2, a vibration motor 3, a spring 4 and a machine base 5; the base is connected to the shakeout machine table 1 through a spring 4, and the The sand collecting bucket 2 is arranged under the sand shaker table 1, and the vibration motor 3 is arranged on the sand collecting bucket 2;

[0045] The shakeout machine table 1 is a cuboid structure with a side opening, and the shakeout machine table 1 has no top plate, and the bottom plate of the shakeout machine table 1 is uniformly provided with mesh holes, and the shakeout machine bottom plate is arranged obliquely. Fixed grids 11 parallel to each other are fixed on the bottom plate, movable grids 12 perpendicular to the fixed grids 11 are installed on the base, and the movable grids 12 and the fixed grids 11 are open at the contact points;

[0046] The upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com