Improved extruder barrel structure

An improved, extruder technology, applied in the field of extruders, can solve the problems of difficult maintenance, high manufacturing cost, resin mixing, etc., and achieve the effect of simple and convenient assembly and maintenance, simple manufacturing process, and improved rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

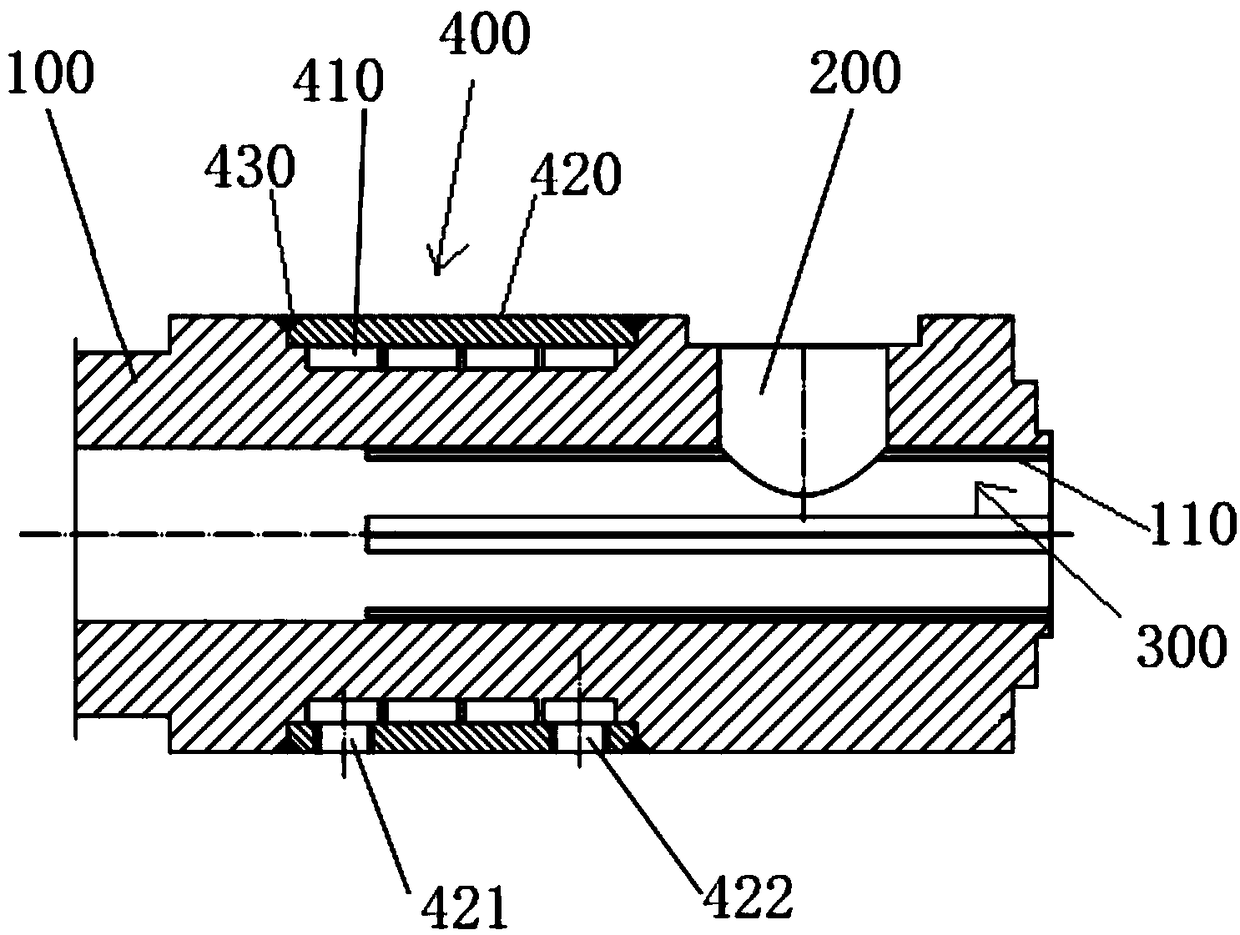

[0015] see figure 2 The improved structure of the extruder barrel shown includes a barrel 100, the outer wall of the barrel 100 is connected with a material inlet 200, and the inner wall of the barrel 100 is circumferentially arranged with a number of concave strips 110 at intervals to form a forced feeding The sleeve 300 , the feed inlet 200 is in communication with the forced feeding sleeve 300 , and the outer wall of the barrel 100 is also provided with a cooling water channel 400 .

[0016] In this embodiment, the outer wall of the barrel 100 is provided with an annular cooling water tank 410, and the annular cooling water tank 410 is covered by an annular wrapping 420. The annular wrapping 420 is provided with a water inlet 421 and a water outlet 422. The side 420 forms the cooling water channel 400 . The gap between the annular cooling water tank 410 and the annular wrapping 420 is sealed by a welding structure 430 .

[0017] The beneficial effects of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com