Manipulator for bottle blowing machine

A technology of manipulators and bottle blowing machines, applied in the field of manipulators, can solve problems such as inability to accurately discharge bottles, clamp head 3 stuck, and inability to accurately align the host machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

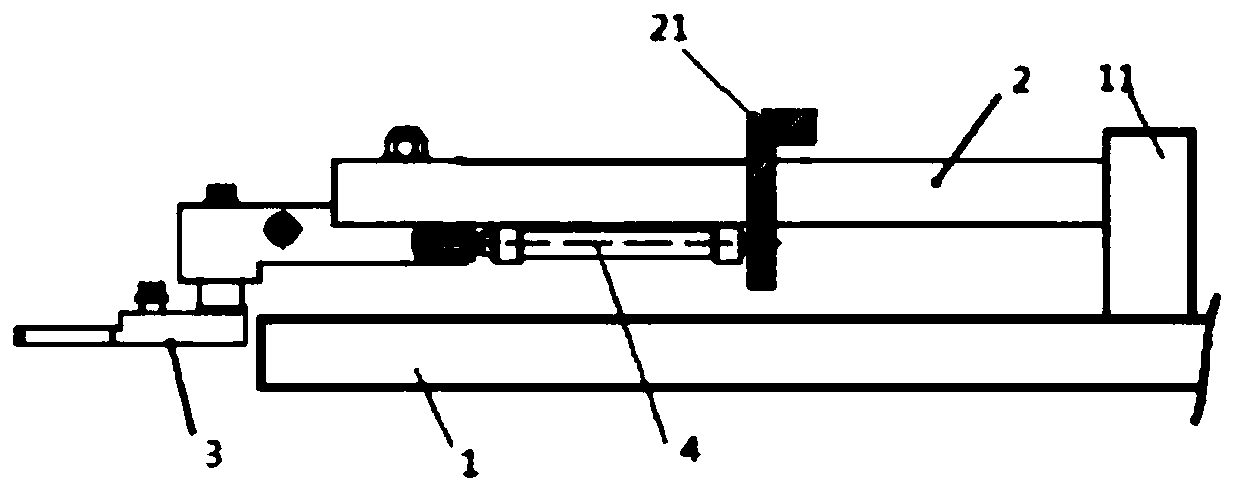

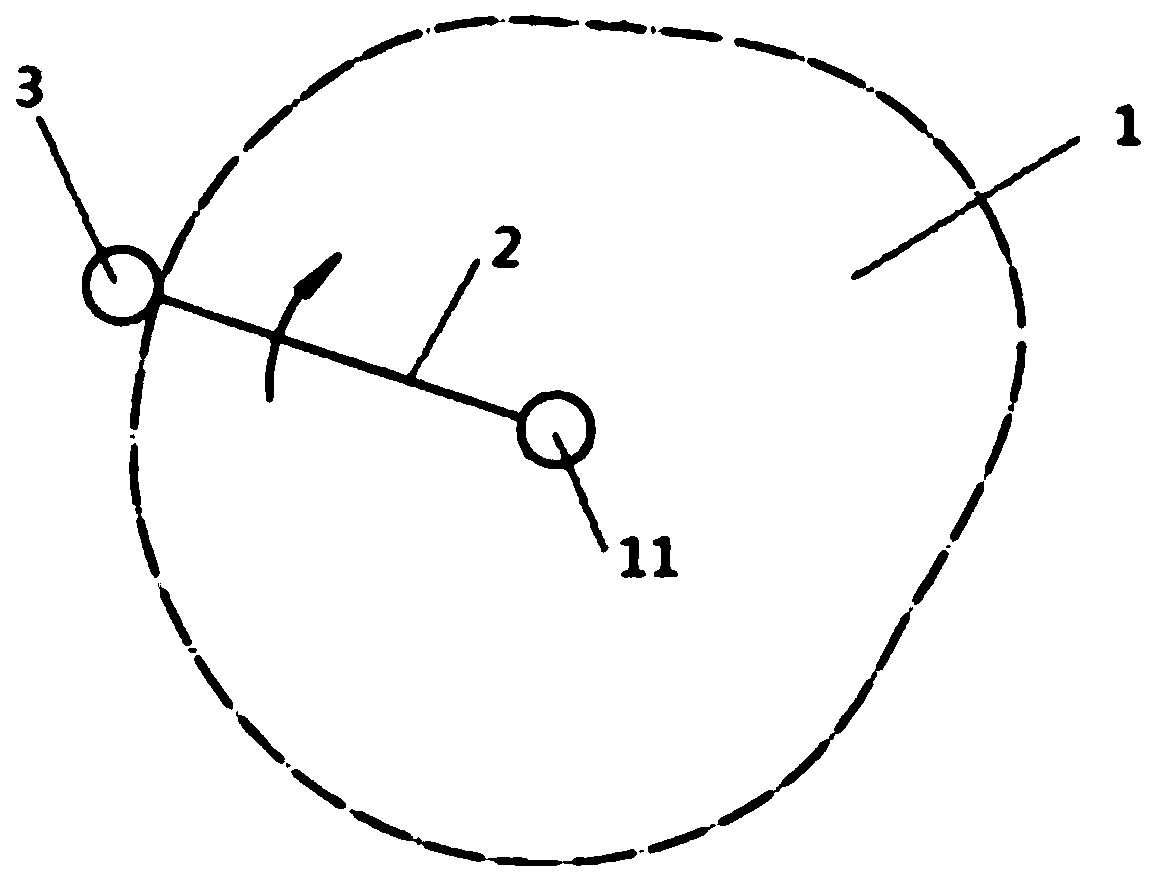

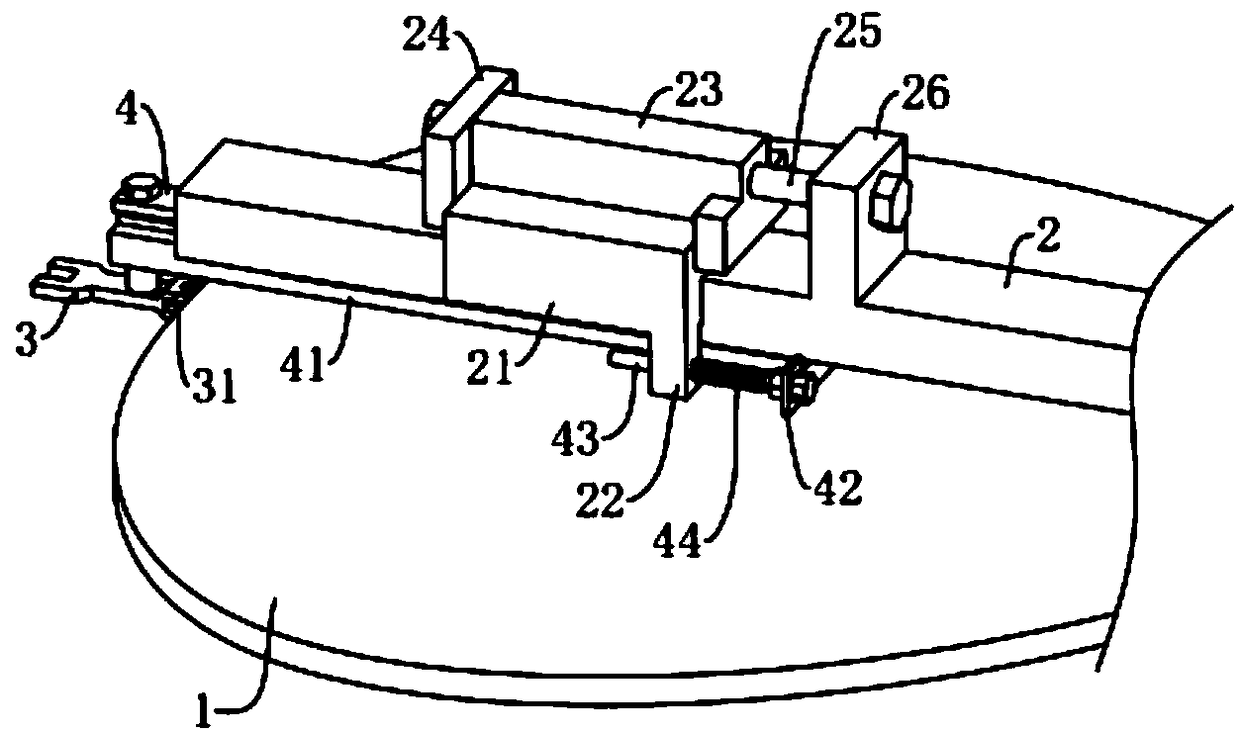

[0026] The structure of a robot arm for a bottle blowing machine provided in this embodiment is shown in the figure.

[0027] The manipulator for a bottle blowing machine includes a central rotating shaft 11 arranged on the base 1, a rotating arm 2 controlled by the central rotation, and a clamp head 3 arranged at the end of the rotating arm 2. The rotating arm 2 corresponds to the base One end of table 1 edge is provided with slideway 28, and slideway 28 extends toward central rotating shaft 11 places along the length direction of rotating arm 2, and sliding block 4 is slidably connected in slideway 28, and fixture head 3 is arranged on sliding block 4, and rotating arm 2 is provided with a connecting frame 21, the connecting frame 21 and the slider 4 are connected by an elastic member 44, the elastic member 44 is in a state of elastic deformation, and in the process of restoring the elastic member 44 to its original shape, it drives the sliding block 4 close to the central sh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap