A creep-proof and step-triggered nested rail vehicle end energy absorbing structure

An energy-absorbing structure and rail vehicle technology, which is applied in railway car body parts, railway vehicle wheel guards/buffers, transportation and packaging, etc. problems, to achieve the effect of easy and orderly crushing, reducing the peak collision force, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

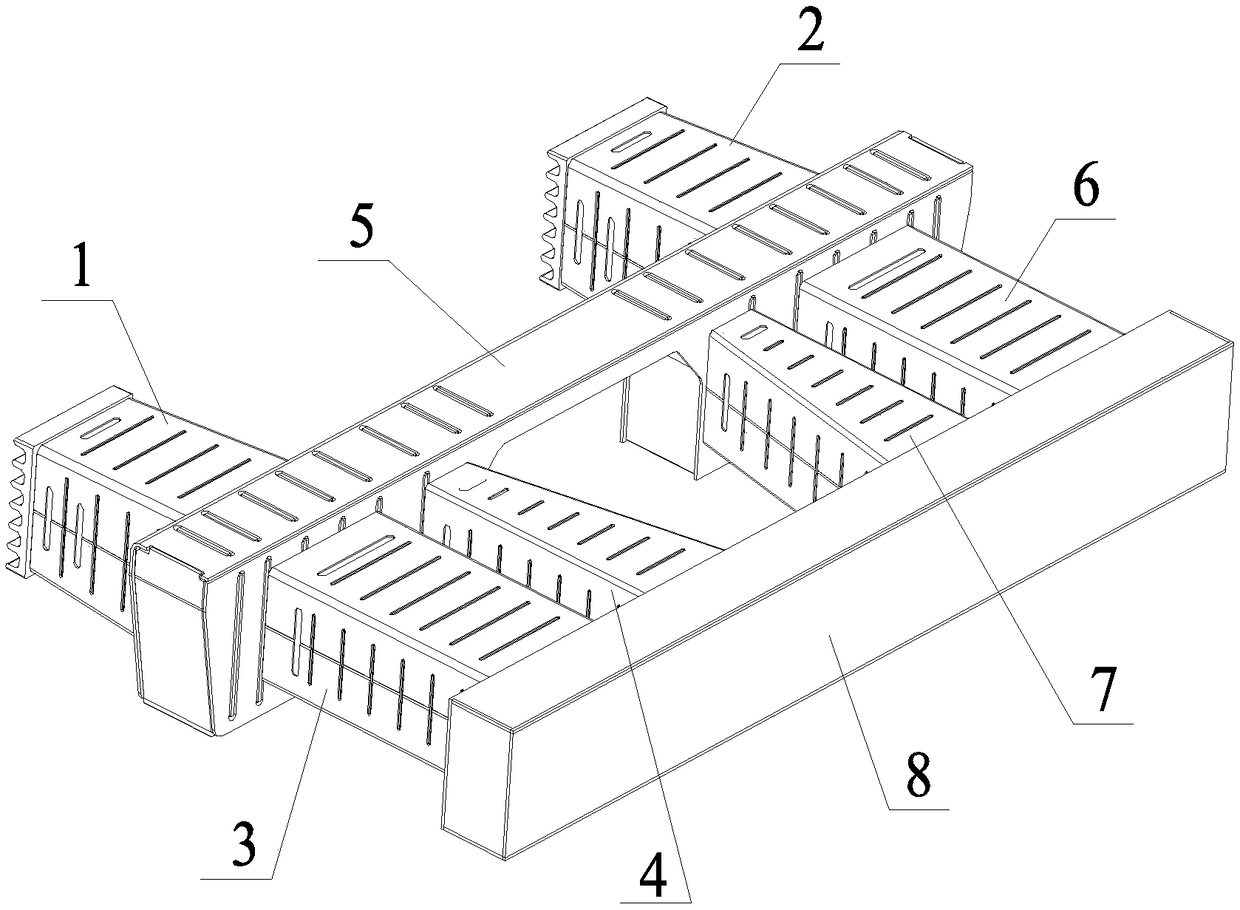

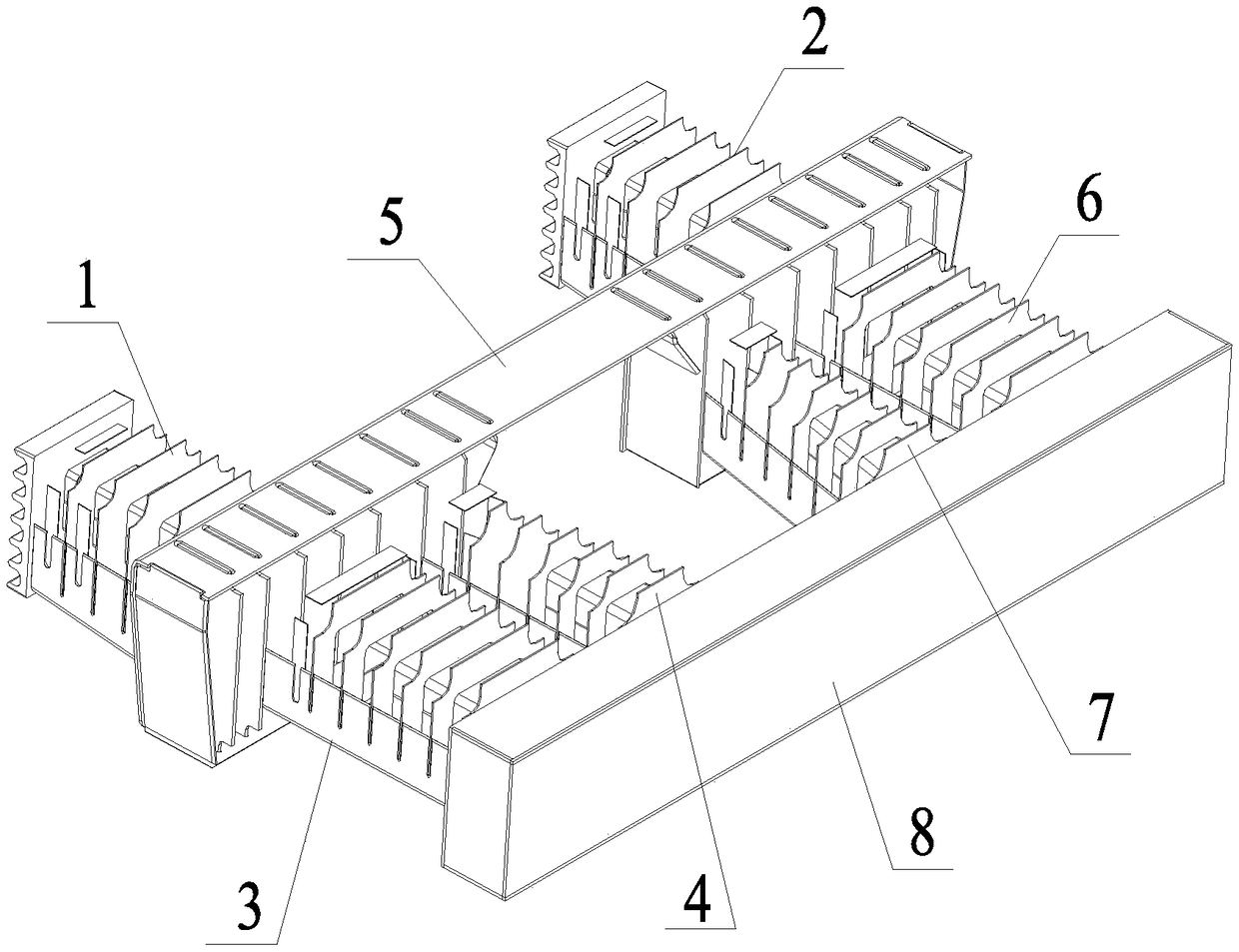

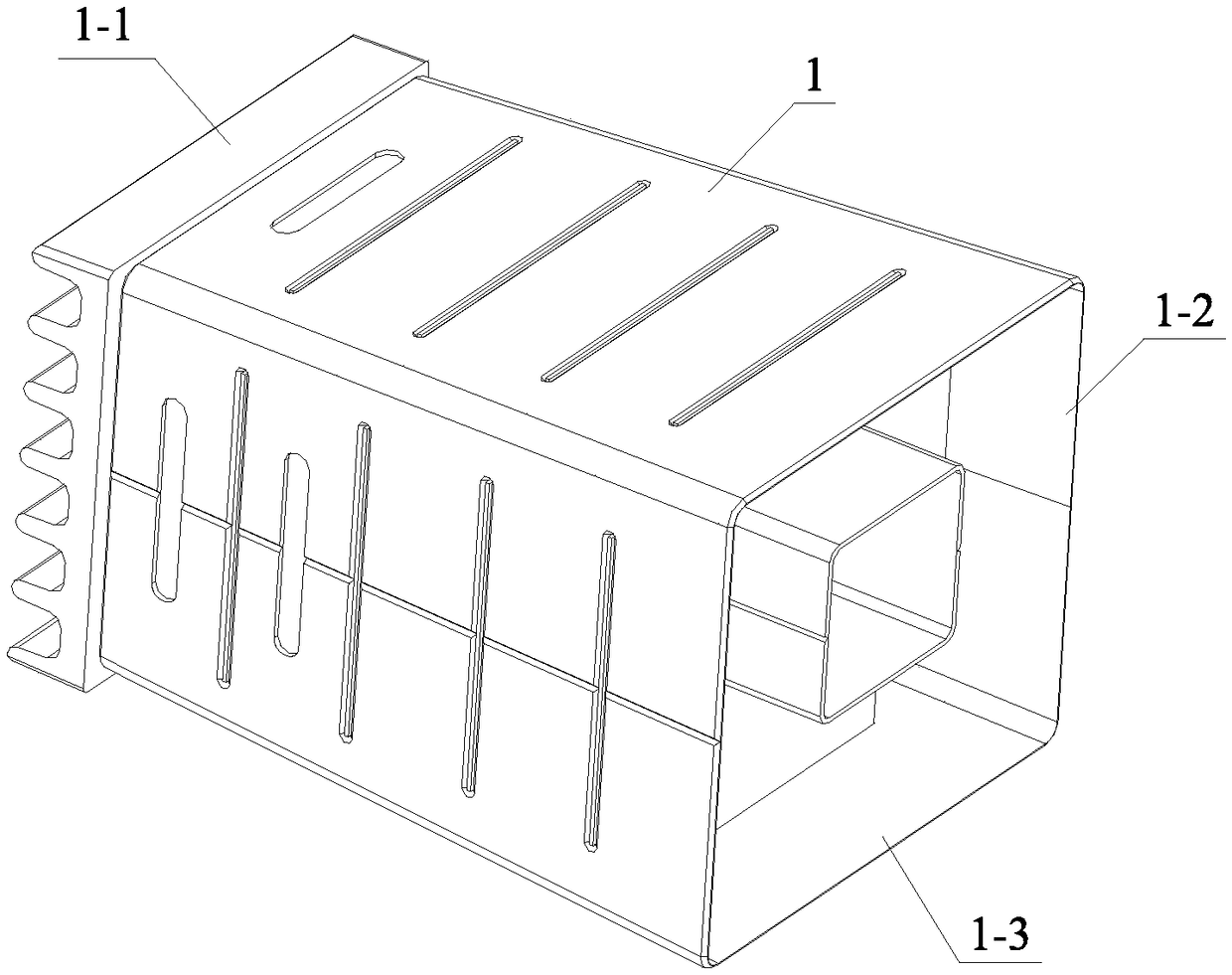

[0033] Such as figure 1 and figure 2 As shown, the anti-climbing and hierarchical triggering nested rail vehicle end energy-absorbing structure of the present invention includes a primary energy-absorbing structure, a secondary energy-absorbing structure, a connecting beam structure 5 and a rear end support beam 8, and the primary energy-absorbing structure The energy structure includes an energy-absorbing structure 1 with anti-climbing teeth on one side and an energy-absorbing structure 2 with anti-climbing teeth on two sides. Variable cross-section box-type energy-absorbing structure 4, two-position side equal-section box-type energy-absorbing structure 6 and two-position side variable-section box-type energy-absorbing structure 7; The structure of the energy-absorbing structure 2 of climbing teeth is exactly the same, the ends of the ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com