Assembling type lifting device for building

A lifting device, construction technology, applied in the direction of lifting device, lifting frame, spring/shock absorber, etc., can solve the problems of lowering lifting device, not enough safety and reliability, not enough convenience and speed, to improve accuracy, good function, Avoid the effect of excessive lifting error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

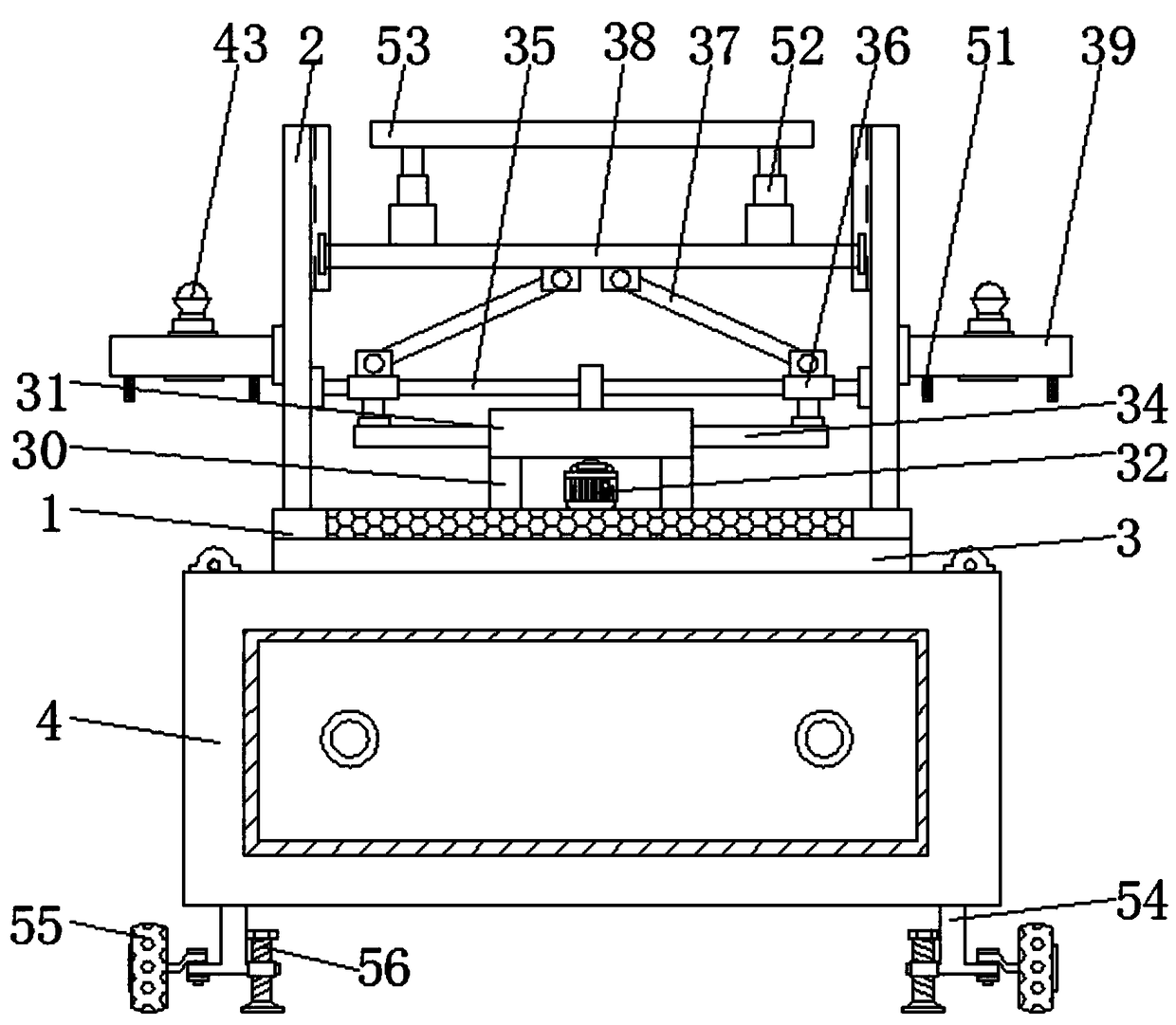

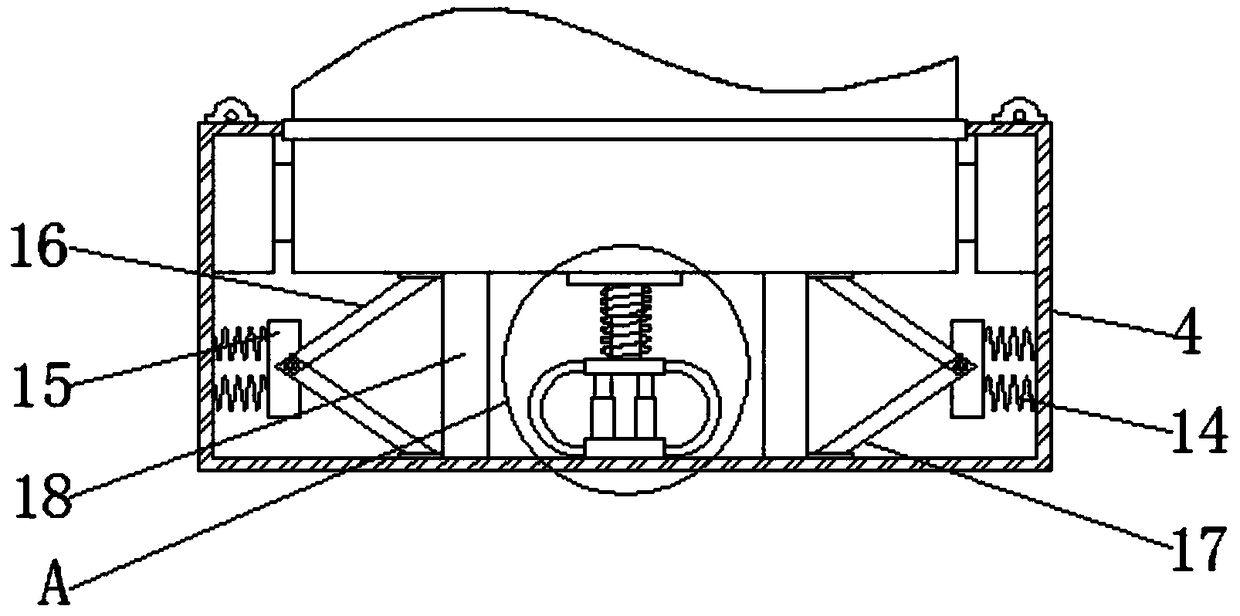

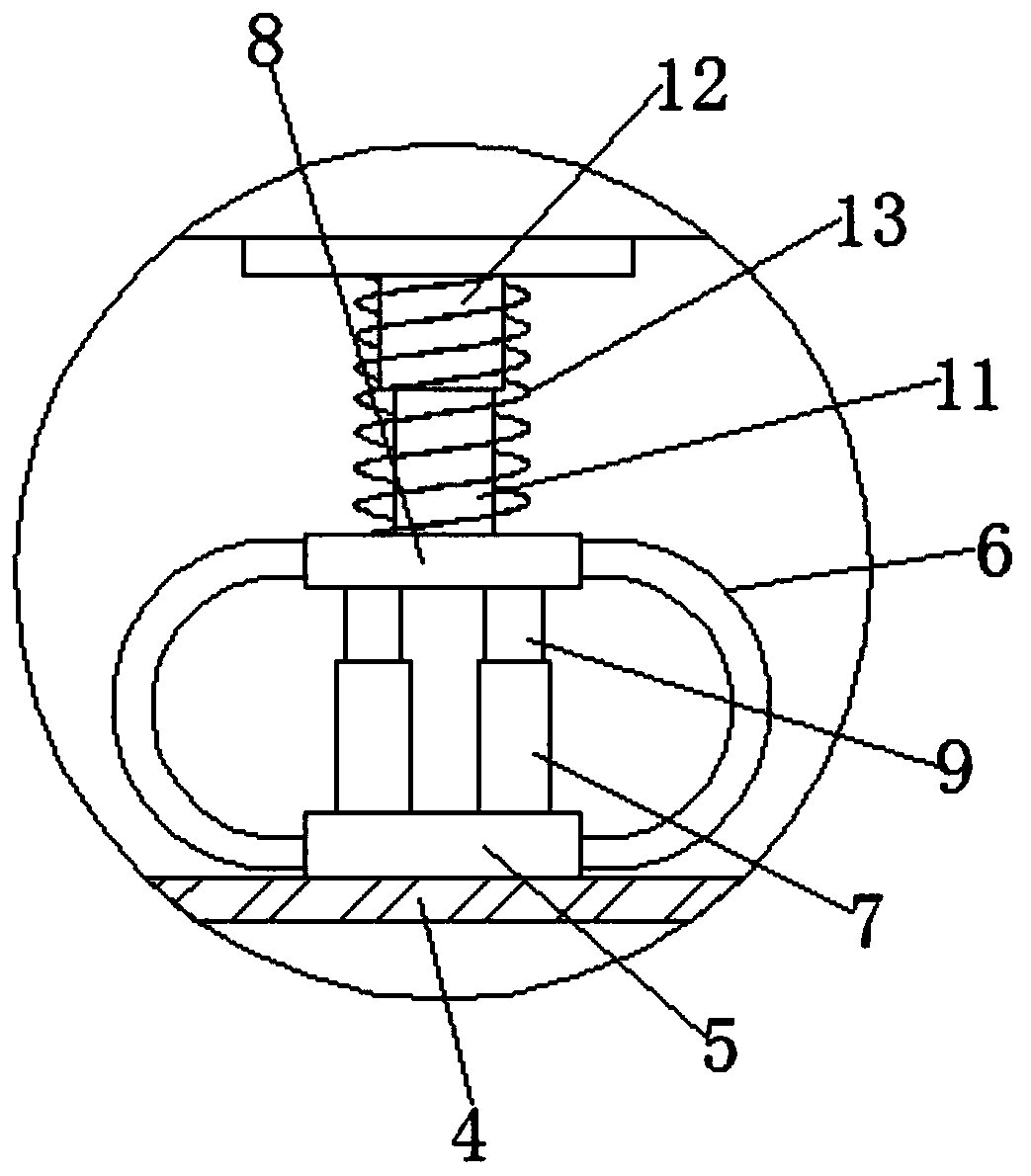

[0037] A lifting device for a prefabricated building, comprising a bottom plate 1, load-bearing vertical plates 2 are fixedly connected to both sides of the top of the bottom plate 1, a heat dissipation box 3 is fixedly connected to the bottom of the bottom plate 1, and a shock absorber is fixedly connected to the bottom of the heat dissipation box 3 Box 4, the bottom of the shock absorbing box 4 cavity is fixedly connected with a support plate 5, both sides of the support plate 5 are fixedly connected with a shock absorbing circular arc plate 6, and both sides of the top of the support plate 5 are fixedly connected with an air cylinder 7, The side of the shock-absorbing circular arc plate 6 away from the support plate 5 is fixedly connected with a fixed plate 8, and both sides of the bottom of the fixed plate 8 are fixedly connected with a piston rod 9, and the bottom end of the piston rod 9 runs through the air cylinder 7 and extends to the air cylinder 7 and the piston rod 9...

Embodiment 2

[0040] A lifting device for a prefabricated building, comprising a bottom plate 1, load-bearing vertical plates 2 are fixedly connected to both sides of the top of the bottom plate 1, a heat dissipation box 3 is fixedly connected to the bottom of the bottom plate 1, and a shock absorber is fixedly connected to the bottom of the heat dissipation box 3 Box 4, the bottom of the shock absorbing box 4 cavity is fixedly connected with a support plate 5, both sides of the support plate 5 are fixedly connected with a shock absorbing circular arc plate 6, and both sides of the top of the support plate 5 are fixedly connected with an air cylinder 7, The side of the shock-absorbing circular arc plate 6 away from the support plate 5 is fixedly connected with a fixed plate 8, and both sides of the bottom of the fixed plate 8 are fixedly connected with a piston rod 9, and the bottom end of the piston rod 9 runs through the air cylinder 7 and extends to the air cylinder 7 and the piston rod 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com