A nitrogen-containing duplex stainless steel cold-rolled profile lubricant composition

A technology of lubricant composition and duplex stainless steel, which is applied in the direction of lubricating composition, base material, petroleum industry, etc., can solve the problems of poor thermal conductivity of stainless steel, and achieve good filterability, good thermal oxidation stability, and good adhesion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A nitrogen-containing dual-phase stainless steel cold-rolled profile lubricant composition, adopting ethylene glycol oleate: the mass ratio of VHVI 4 = 1:2 is compounded as a compound semi-synthetic base oil, and is blended with a variety of compound additives, wherein The acid value of ethylene glycol oleate is <8mgKOH / g, and the mass percentage of each component is shown in the following table:

[0036]

[0037]

[0038] The sum of the above components is 100%.

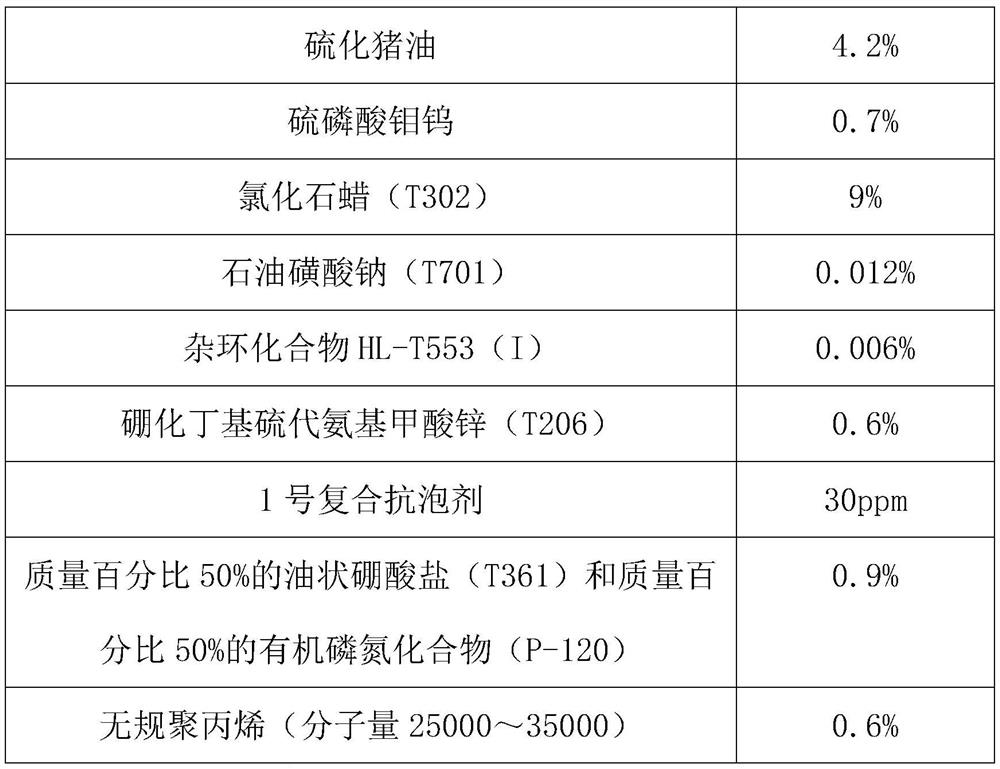

Embodiment 2

[0040] A nitrogen-containing dual-phase stainless steel cold-rolled profile lubricant composition, adopting ethylene glycol oleate: the mass ratio of VHVI 4 = 1:2 is compounded as a compound semi-synthetic base oil, and is blended with a variety of compound additives, wherein The acid value of ethylene glycol oleate is <8mgKOH / g, and the mass percentage of each component is shown in the following table:

[0041]

[0042]

[0043] The sum of the above components is 100%.

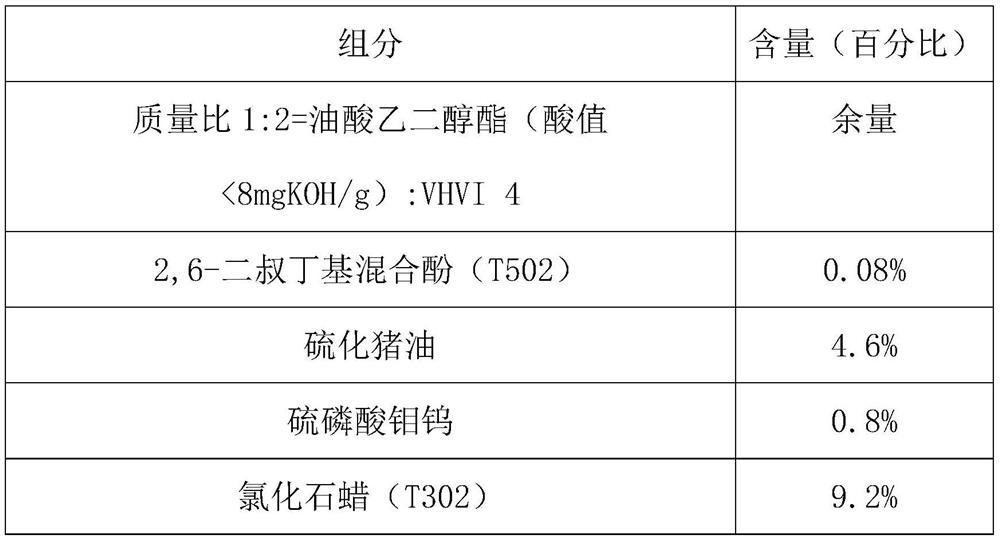

Embodiment 3

[0045] A nitrogen-containing dual-phase stainless steel cold-rolled profile lubricant composition, adopting ethylene glycol oleate: the mass ratio of VHVI 4 = 1:2 is compounded as a compound semi-synthetic base oil, and is blended with a variety of compound additives, wherein The acid value of ethylene glycol oleate is <8mgKOH / g, and the mass percentage of each component is shown in the following table:

[0046]

[0047]

[0048] The sum of the above components is 100%.

[0049] The typical technical index of embodiment 1 is as shown in the table below:

[0050]

[0051]

[0052] The typical technical index of embodiment 2 is as shown in the following table:

[0053]

[0054]

[0055] The typical technical indicators of the implementation of 3 are shown in the following table:

[0056]

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com