Electrolytic plate barrel plating device facilitated taking and discharging materials

An electrolytic plate, picking and discharging technology, applied in the electrolytic process, electrolytic components, etc., can solve the problems of not being able to meet modern production, increase the working time of users, increase the working intensity of users, etc., to increase capacity and save a lot of time , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

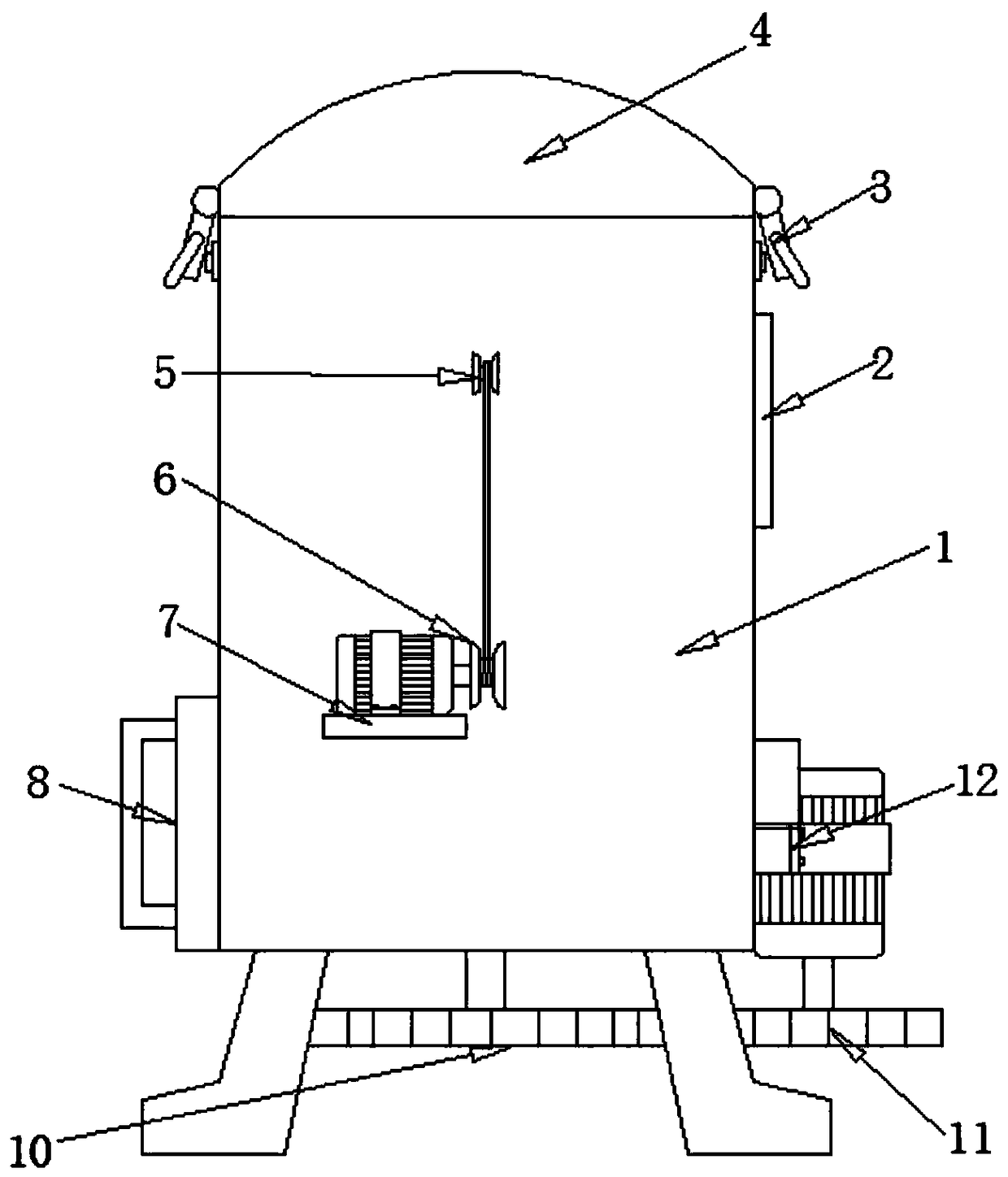

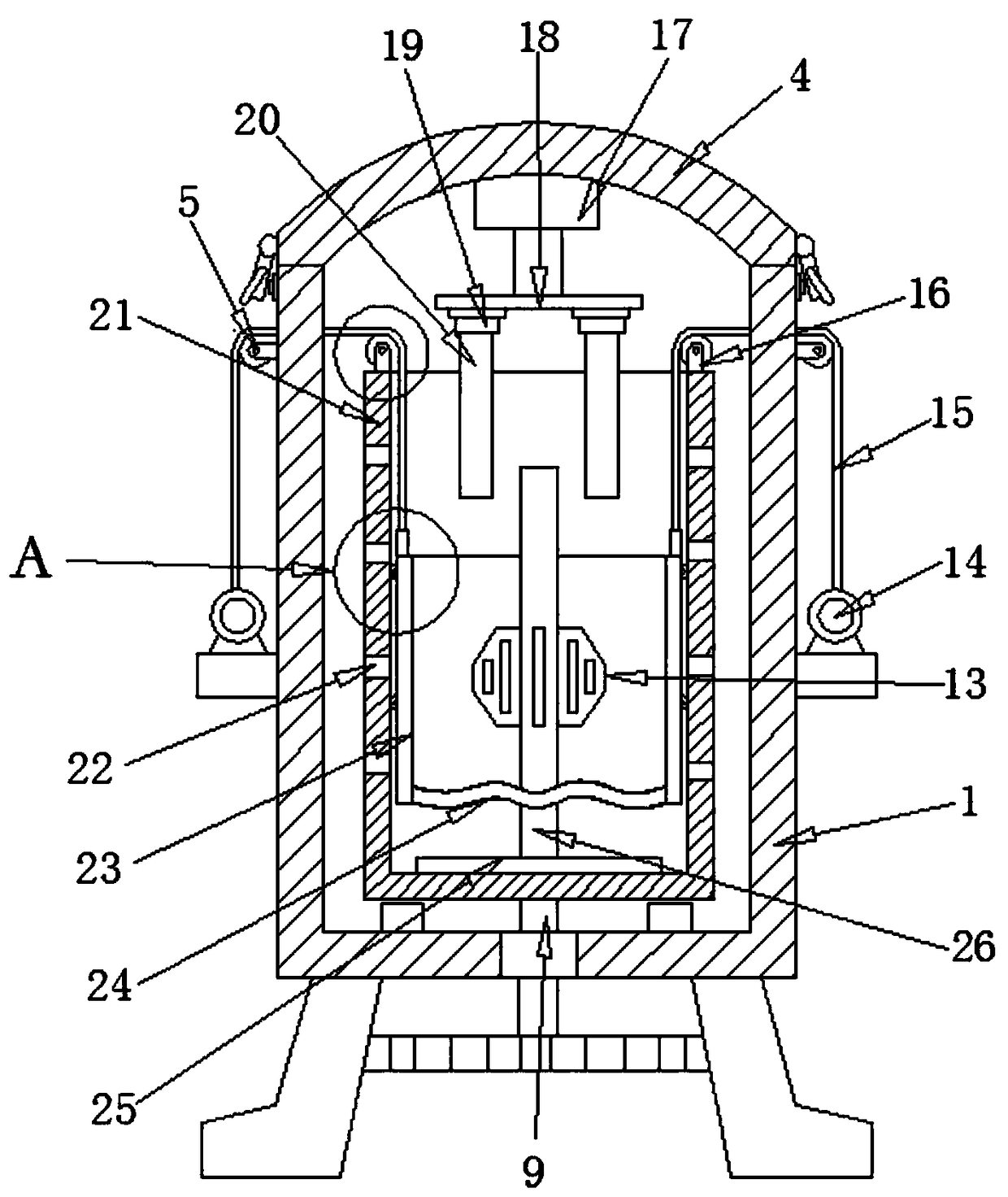

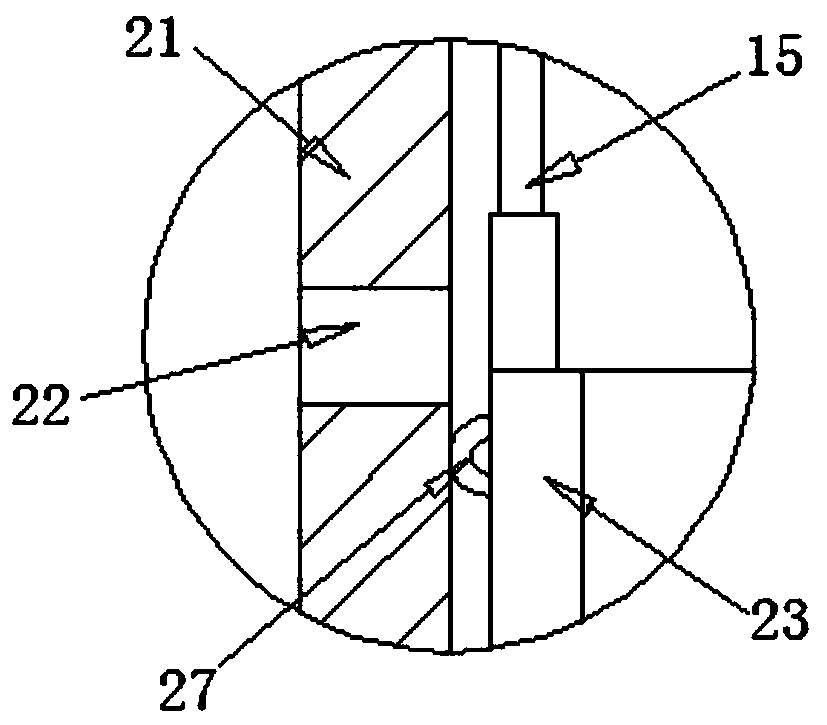

[0022] refer to Figure 1-4 , an electrolytic plate barrel plating device that is convenient for taking and discharging materials, comprising an electroplating box 1 and a retrieving net bucket 23, a stirring motor 12 is fixed on the outer wall of one side of the electroplating box 1 by bolts, and the output shaft of the stirring motor 12 is welded with a first gear 11. There is a groove at the bottom of the electroplating box 1, and the groove is welded with a bearing 9, and the inner wall of the bearing 9 is welded with a vertical transmission rod 26, and the end of the transmission rod 26 located on the outer wall of the electroplating box 1 is welded with a second...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap