Dual-layer eyelet lace and weaving technology thereof

A double-layer, shoe eyelet technology, applied in the field of weaving, can solve the problems of loose connection between the eyelet and the main body of the shoe eyelet, poor tensile strength, easy to move, etc., to achieve good market prospects, high production efficiency, and easy penetration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

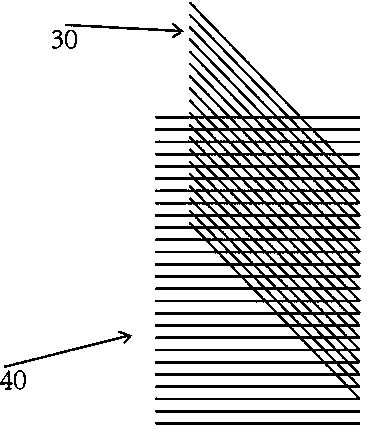

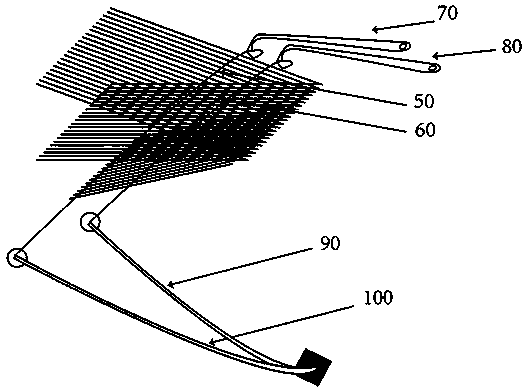

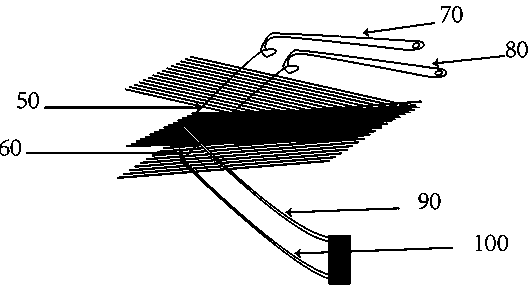

[0047] A total of 253 warp yarns are worn, and the material used is 150 denier twisted Teflon, the surface weft yarn is 150 denier twisted Teflon, and the bottom weft yarn is 300 denier twisted Teflon. The eyelets are 9mm wide and the body is 15.2mm wide.

Embodiment 2

[0049] A total of 223 warp yarns are worn, and the material used is 150 denier twisted Teflon, the surface weft yarn is 150 denier twisted Teflon, and the bottom weft yarn is 300 denier twisted Teflon. The eyelets are 6mm wide and the body is 10.6mm wide.

[0050] The key point of the design of the present invention is: the shoe eyelet belt formed by the double-layer structure of the present invention makes the main body ribbon and the shoe mesh form a whole, and the connection is natural and firm; The density should be small, so that the eyelets are softer and the shoelaces are easier to penetrate; when the shoelaces are tied to the eyelets, that is, when the eyelets are subjected to external tension, the eyelets have the characteristics of no deformation and no movement, making the entire shoelace The performance of the shoe eyelet is improved; compared with the single-drawstring shoe eyelet and the single-side drawstring shoe eyelet, it has the advantages of concealment, li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com