Core anti-corrosion anchor cable anchorage for mining

An anchor and cable technology, which is used in mining equipment, bolt installation, earthwork drilling, etc., can solve problems such as hidden roadway support, anchor failure, and anchor corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0023] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

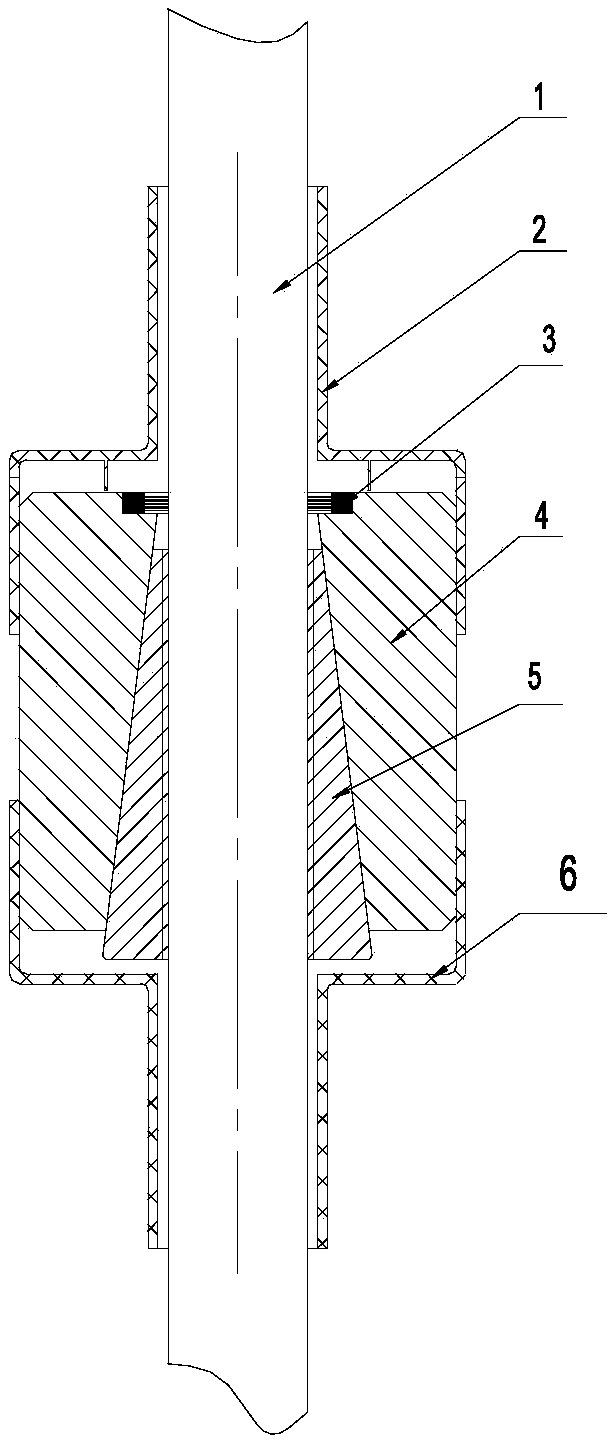

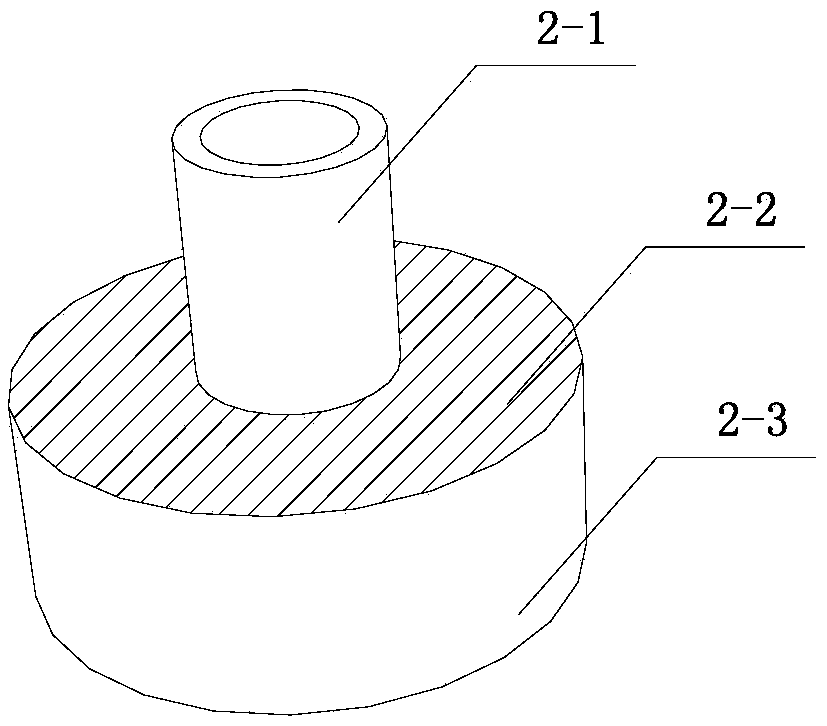

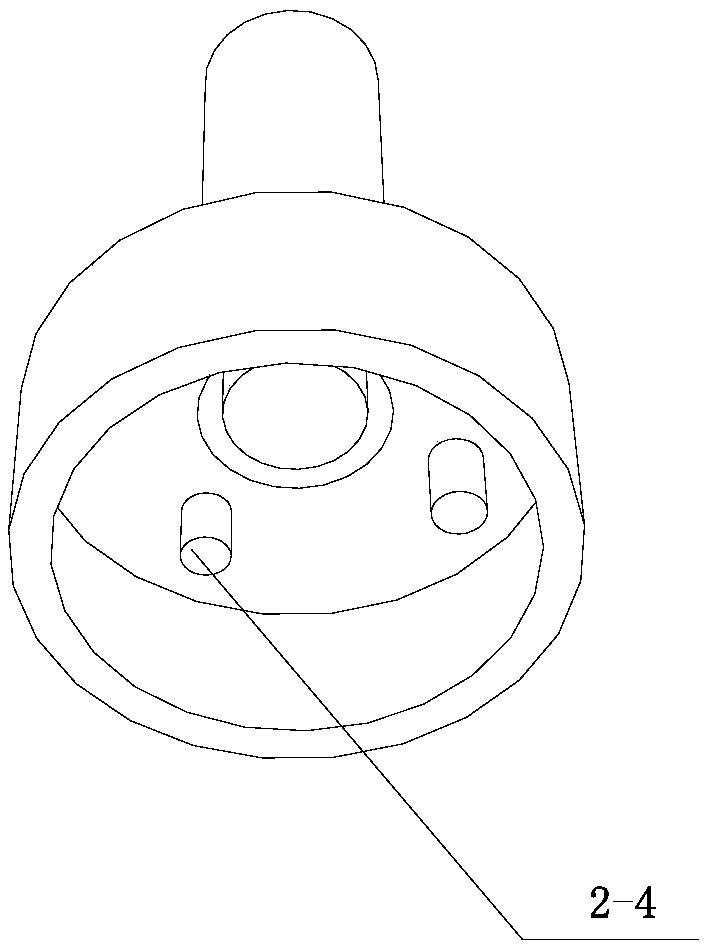

[0024] see Figure 1 to Figure 3 : A mine core anti-corrosion anchor cable anchorage, which is applied to the anti-corrosion of the anchorage inside the anchorage installation place and the steel strand 1; the same technical characteristics as the traditional technology include: the anchorage includes clamping on The clip 5 on the outer wall of the steel strand 1 and the anchor ring 4 sleeved on the clip 5;

[0025] In order to prevent the corrosive liquid from entering the gap between the outer wall of the steel strand 1 and the inner wall of the anchor ring 4, this patent is based on the traditional technology: a sealing member is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com