A slide valve of screw compressor with airflow pulsation attenuation function

A screw compressor and airflow pulsation technology, which is applied in the direction of machines/engines, liquid fuel engines, pumping devices for elastic fluids, etc., can solve problems such as airflow pulsation, achieve less pressure loss, attenuate airflow pulsation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

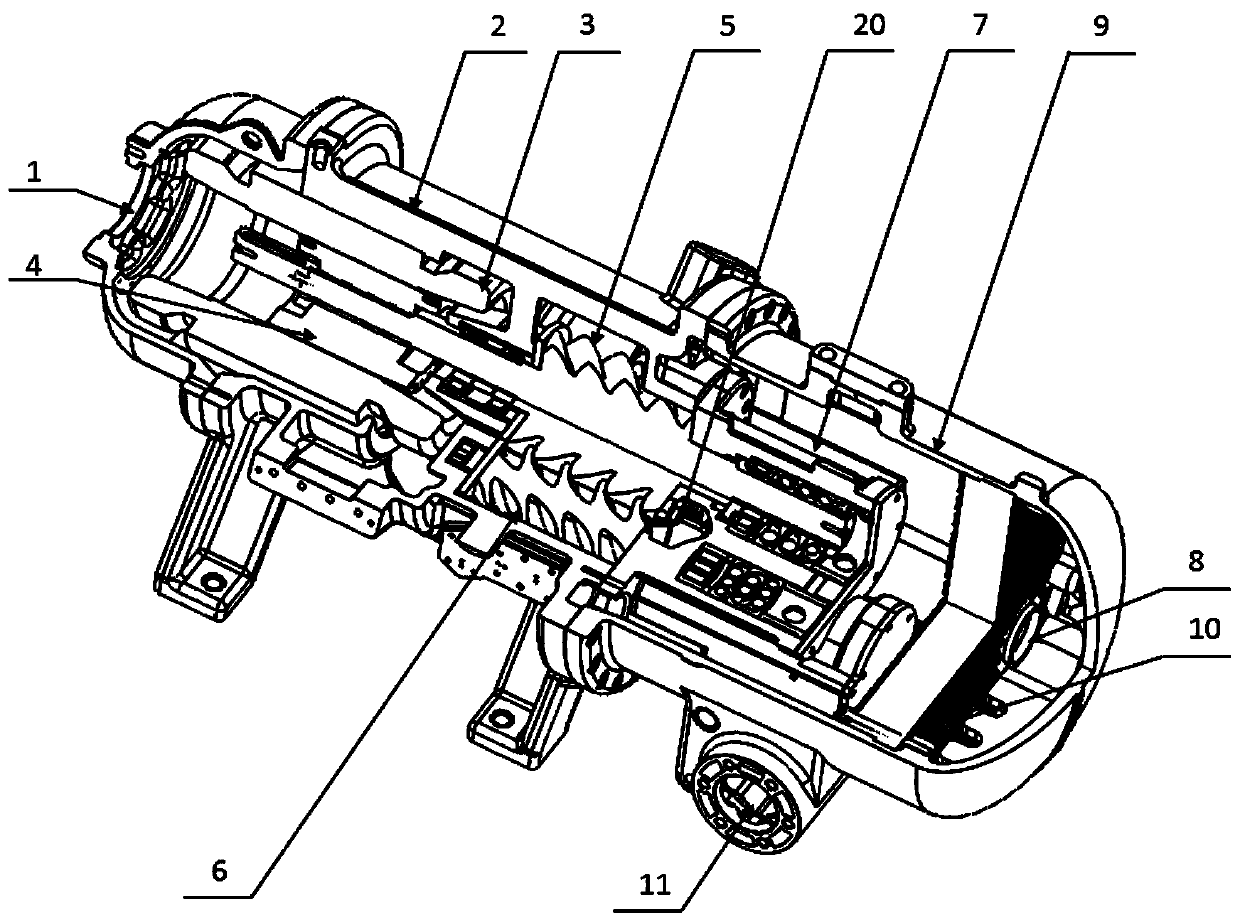

[0023] see figure 1 , the screw compressor inhales gas from the suction port 1 of the suction section, and then enters the suction chamber of the body 2 from the gap between the compressor body 2 and the motor stator 3 and the gap between the motor stator 3 and the electronic rotor 4, and enters the air suction cavity of the body 2 in the male rotor 5 and the female rotor 6 are compressed to the exhaust section under the meshing action, and then enter the exhaust cavity from the exhaust port through the exhaust bearing seat 7, and then are discharged into the exhaust oil separator barrel 9 through the exhaust pipe 8, and the built-in After the oil and gas in the oil filter 10 are separated, they are discharged from the exhaust port 11 . Through the axial movement of the slide valve 20 of the screw compressor, the exhaust gas volume of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com