Single-cylinder double-cavity reciprocating damper

A reciprocating, damper technology, applied in shock absorbers, shock absorbers, liquid shock absorbers, etc., can solve the problems of low linear speed, high cost, increased device cost, etc., and achieve simple sealing structure and good damping effect. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

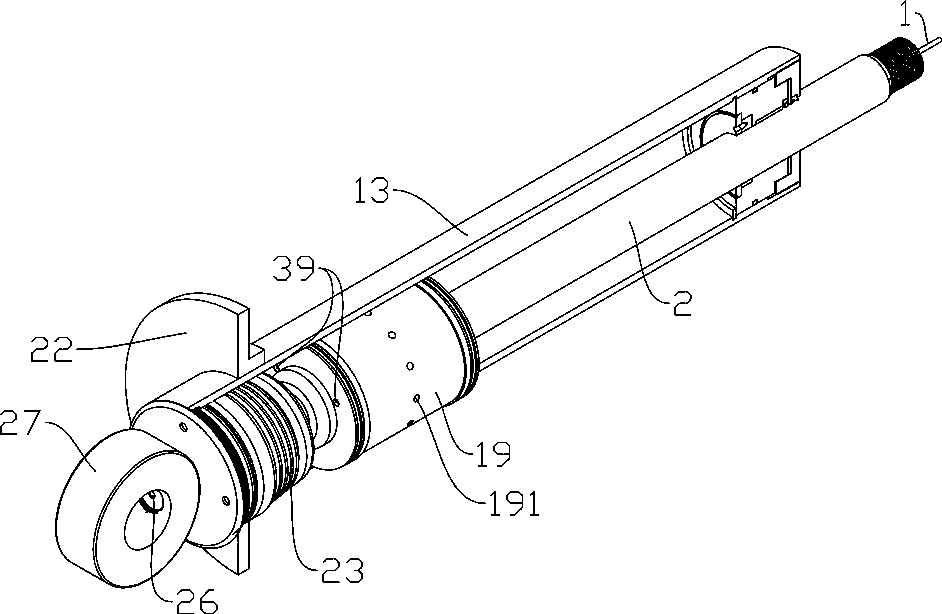

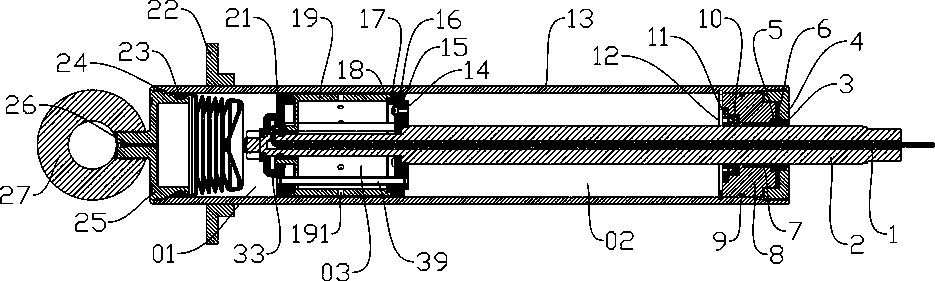

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] refer to Figure 1 to Figure 7 , a single-tube double-chamber reciprocating damper involved in the present invention, comprising a cylindrical hollow cylinder 13, a reciprocating piston disposed in the cylinder 13, a piston rod 2 is fixed on the piston, the One end of the piston rod 12 extends out of the cylinder body 13; one end of the cylinder body 13 close to the piston is provided with an end cap for sealing, and the other end on the cylinder body 13 is provided with a seal for sealing, wherein the piston, the end cap , seals and the like specifically have the following structures.

[0028] Such as Figure 5 As shown, the piston is provided with a channel 39 formed by a pipe fitting, and the channel 39 communicates with the cavities 01 and 02 on both sides of the cylinder cavity separated by the piston; the piston is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com