Instantaneous opening device for molten liquid in high temperature and high pressure container

A high-temperature, high-pressure, opening device technology, applied in the direction of pressure vessels, gas/liquid distribution and storage, fixed-capacity gas storage tanks, etc., can solve the problems of difficult control of holding time, high-temperature and high-pressure resistance performance needs to be improved, and achieve good application status , control the heat preservation time, and improve the effect of heat preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

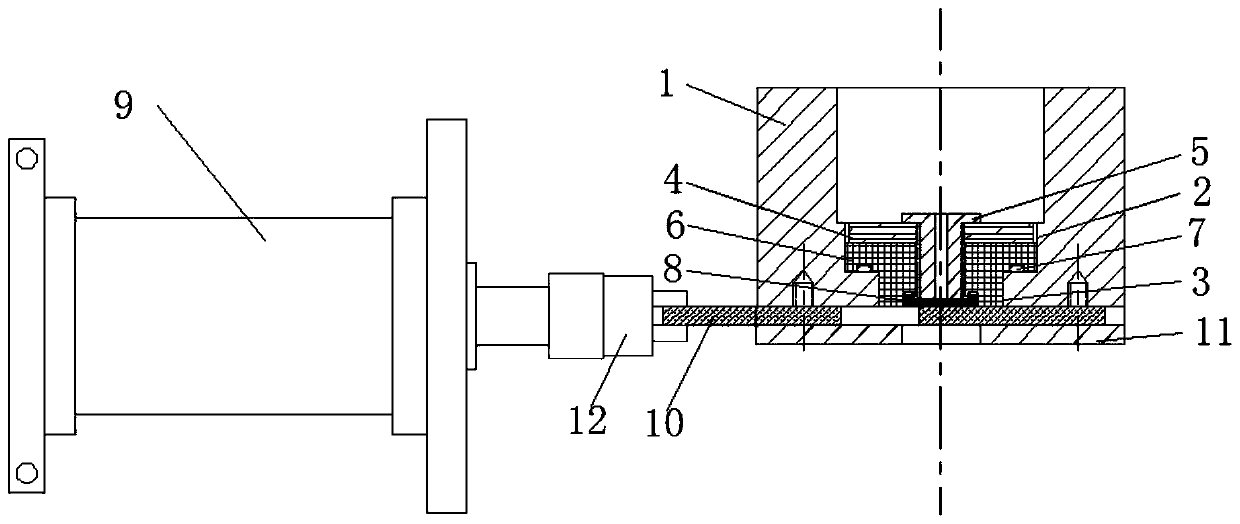

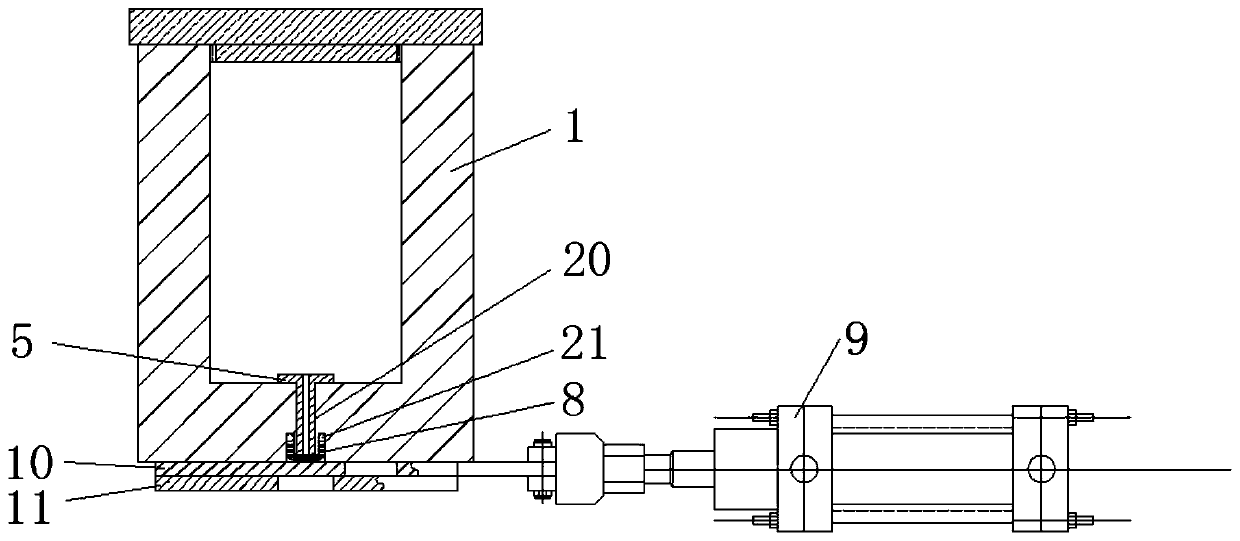

[0023] Specific Embodiment 1: The instant opening device for the molten liquid in the high-temperature and high-pressure container of this embodiment includes a reactor 1, a tablet 4, a nozzle 5, a nozzle bracket 6, a sealing pretensioner 8, an upper slide 10, a lower slide 11 and a drag The device 9 is provided with two-stage stepped circular holes along the thickness direction of the bottom of the reactor 1, the first stepped circular hole 2 is located on the upper part of the second stepped circular hole 3 and the diameter of the first stepped circular hole 2 is larger than the second stepped circular hole 3 in diameter;

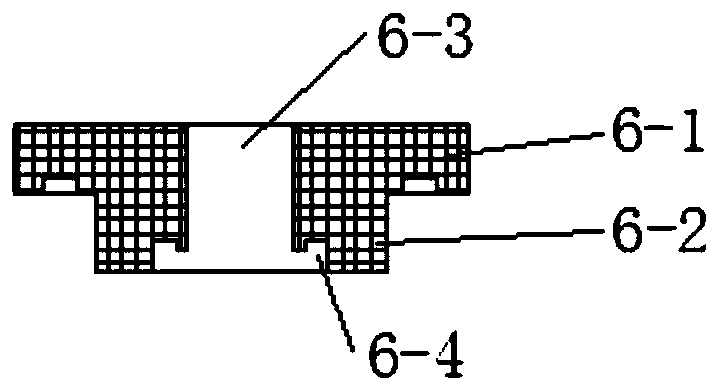

[0024] The nozzle bracket 6 is composed of a disc-shaped frame body part 6-1 and a cylindrical part 6-2 to form a coaxial integrated structure, and an insertion hole 6-3 is opened along the central axis of the nozzle bracket 6, and the end surface of the cylindrical part 6-2 There is a ring groove 6-4, the nozzle bracket 6 is inserted into the two-stage s...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the material of the nozzle 5 is graphite, W, graphite / Cu (graphite copper infiltration), W / Cu (tungsten copper infiltration), C / C, HfB 2 Ultra-high temperature ceramics, ZrB 2 Ultra-high temperature ceramics, TaB 2 Ultra-high temperature ceramics, TiB 2 Ultra-high temperature ceramics, ZrC ultra-high temperature ceramics, HfC ultra-high temperature ceramics, TaC ultra-high temperature ceramics or TiC ultra-high temperature ceramics.

[0030] Each part of the nozzle in this embodiment can be made of different materials.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the lower surface of the disc-shaped frame body part 6-1 of the nozzle holder 6 has a sealing ring groove, and a first sealing ring groove is arranged in the sealing ring groove. Circle 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com